UHMWPE conveyor roller sleeves, crafted from ultra-high molecular weight polyethylene with a molecular weight exceeding 1.5 million g/mol, are advanced components designed to enhance the performance and longevity of conveyor roller systems. These sleeves are used to encase conveyor rollers, providing exceptional wear resistance, low friction, and corrosion resistance, making them ideal for demanding industrial applications such as mining, quarrying, port operations, and bulk material handling. The unique properties of UHMWPE ensure that these sleeves outperform traditional materials like steel, HDPE, or nylon in harsh environments where abrasion, impact, and chemical exposure are common.

The UHMWPE conveyor roller sleeve boasts wear resistance 7 times greater than steel and 3 times that of nylon, significantly extending the service life of rollers in abrasive conditions, such as coal, ore, or grain transport. Its impact resistance is equally impressive, with a toughness 5 times that of HDPE, 3 times that of nylon, and 10 times that of PTFE, allowing it to withstand heavy loads and repeated impacts without cracking or deforming. The material’s low friction coefficient (0.009 compared to 0.013 for steel) and self-lubricating, anti-adhesion properties prevent material buildup on the roller surface, reducing belt damage and ensuring smooth, energy-efficient operation. This low friction also contributes to noise reduction, creating a quieter and safer working environment.

UHMWPE’s chemical stability ensures resistance to corrosive substances, including acids, alkalis, salts, and seawater, making these sleeves suitable for harsh environments like chemical processing plants or coastal port facilities. The material’s anti-aging properties, with a service life of over 20 years without degradation under UV exposure or extreme temperatures (down to -196°C), further enhance its durability. The lightweight nature of UHMWPE—approximately one-third the weight of steel—reduces the overall weight of conveyor systems, lowering energy consumption by up to 25% and simplifying installation and maintenance.

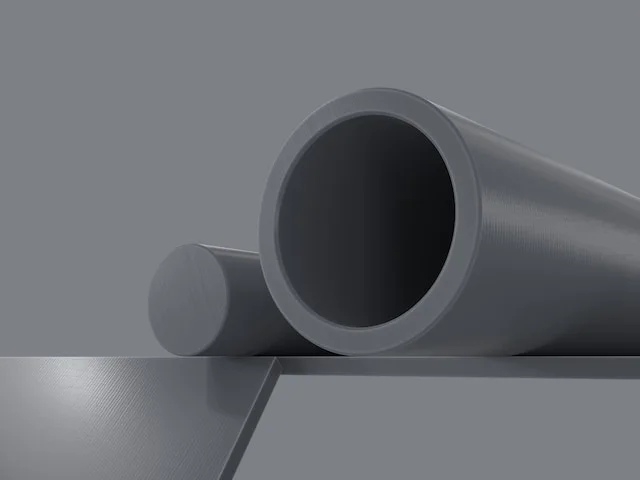

These sleeves feature an effective sealing system, typically incorporating a labyrinth seal that prevents dust and water ingress into the bearing housing, ensuring reliable performance in wet or dusty conditions. The narrow clearance between the bearing shell and shaft forms a secondary seal, further enhancing protection. The anti-adhesion properties of UHMWPE ensure that the sleeve repels dust and debris, reducing maintenance needs and downtime. Available in custom sizes with outer diameters from 50mm to 1200mm and wall thicknesses up to 65mm, UHMWPE conveyor roller sleeves can be tailored to fit various roller types, including standard, impact, return, and guide rollers, meeting specific operational requirements.

In mining, UHMWPE conveyor roller sleeves are widely used to transport abrasive materials like coal, ores, and minerals, where their durability and low maintenance requirements reduce operational costs. In port and dock operations, they handle bulk materials like grain or cement, withstanding constant abrasion and harsh weather conditions. The food and beverage industry also benefits from their hygienic, easy-to-clean surfaces, which resist contamination and meet stringent regulatory standards. Compared to steel rollers, UHMWPE sleeves offer a service life over three times longer, while their lightweight design and energy efficiency make them a cost-effective alternative to HDPE or metal rollers.

The eco-friendly design of UHMWPE conveyor roller sleeves, requiring no lubrication or frequent maintenance, reduces operational costs by up to 95% compared to traditional metal rollers. Their smooth surface improves conveyor efficiency by over 20%, saving energy and extending the lifespan of conveyor belts. For inquiries or custom orders, contact Shandong Buoy and Pipe Industry Co., Ltd. at sales@buoyandpipe.com.