UHMWPE sheets, made from ultra-high molecular weight polyethylene with a molecular weight exceeding 3 million g/mol,

are versatile, high-performance materials designed for demanding applications such as marine fender pads, conveyor

linings, and industrial linings. Renowned for their exceptional wear resistance—7 times greater than steel and 3

times that of nylon—these sheets are ideal for environments involving abrasive materials, heavy impacts, or

corrosive conditions. Their low friction coefficient (0.009 compared to 0.013 for steel) and self-lubricating,

non-adhesive properties prevent material buildup, ensuring smooth operation and reduced maintenance in applications

like bulk material handling, port operations, and construction.

UHMWPE Sheet Properties and Engineering Properties

| # |

Item |

Test Method |

Unit |

Criteria |

Result |

| 1 |

Density |

ISO 1183 |

g/cm³ |

> 0.94 |

1.05 |

| 2 |

Tensile Strength |

ISO 527 |

N/mm² |

> 17 |

22 |

| 3 |

Elongation at Break |

ISO 527 |

% |

> 50% |

140% |

| 4 |

Abrasion (Sand Slurry) |

ISO 15527 |

% |

< 140% |

120% |

| 5 |

Notched Impact Strength (Charpy) |

ISO 11542-2 |

mJ/mm² |

> 50 |

80 |

| 6 |

Hardness (Shore D) |

ISO 868 |

D |

> 62 |

68 |

| 7 |

Melt Point (DSC) |

ISO 11357 |

°C |

> 135 |

139 |

| 8 |

Water Tightness |

GB/T 328.10-2007 |

- |

Non Leakage |

Non Leakage |

| 9 |

Water Absorption |

GB/T 1034-2008 |

% |

- |

6.15 × 10⁻³ |

| 10 |

Vicat Softening Temperature |

GB/T 1633-2000 |

°C |

- |

137 |

In marine applications, UHMWPE sheets serve as fender facing pads, dock bumpers, and car stoppers, providing

superior impact resistance (5 times that of HDPE) and corrosion resistance against seawater, acids, and alkalis.

Unlike steel, UHMWPE fenders do not require painting, as the color is molded into the material, reducing maintenance

costs and resisting marine growth adhesion. The sheets’ resilience and stretch resistance allow them to absorb

collision forces and rebound without deformation, making them ideal for protecting vessels and dock structures

during berthing. Their non-toxic, environmentally friendly properties ensure no pollution during manufacturing or

use, aligning with sustainable marine operations.

For bulk material handling, UHMWPE sheets are used as silo liners, chute liners, and bunker liners for materials

like coal, lime, cement, mineral powder, salt, and grain. Their low water absorption (

UHMWPE sheets are also used in construction as outrigger pads for crane lifting and temporary road mats, offering

lightweight yet robust support under heavy loads. In the sports industry, they serve as synthetic ice rink panels

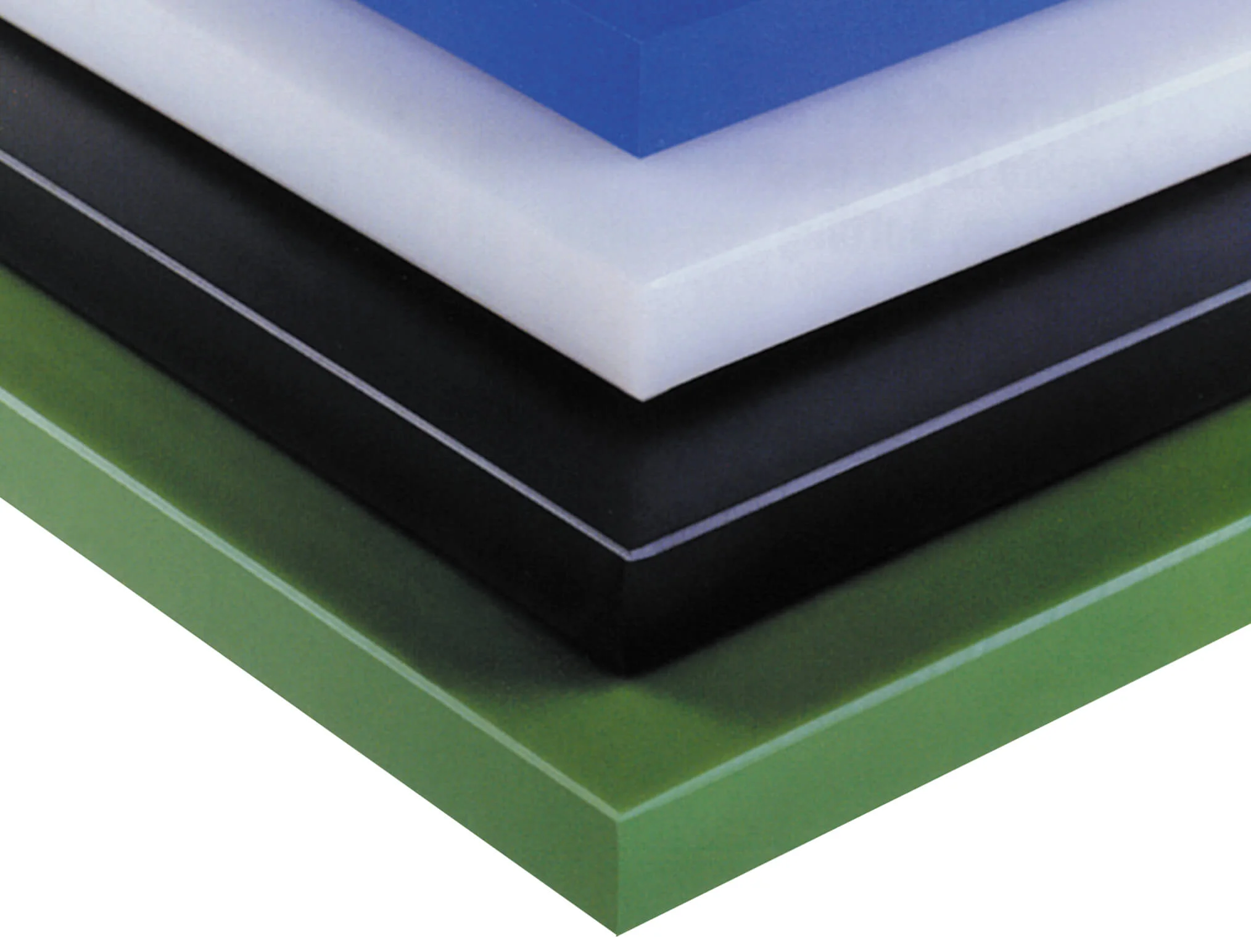

and barriers due to their low friction and durability. Available in custom sizes (50-1200mm width, up to 65mm

thickness) and colors (natural, black, gray, yellow, white, blue, green, red), these sheets can be easily fabricated

and fastened to steel, concrete, wood, or rubber surfaces using bolts or adhesives, simplifying installation. Their

anti-aging properties ensure a service life of over 20 years without degradation under UV exposure or extreme

temperatures (down to -196°C), and they pass 200-hour Xenon lamp aging tests without fading.

Compared to alternatives like HDPE or steel, UHMWPE sheets offer superior abrasion resistance, impact strength, and

chemical stability, making them a cost-effective choice for long-term use. Their lightweight design—approximately

one-third the weight of steel—reduces installation costs and energy consumption in dynamic applications like

conveyor systems. For inquiries or custom orders, contact Shandong Buoy and Pipe Industry Co., Ltd. at

sales@buoyandpipe.com.

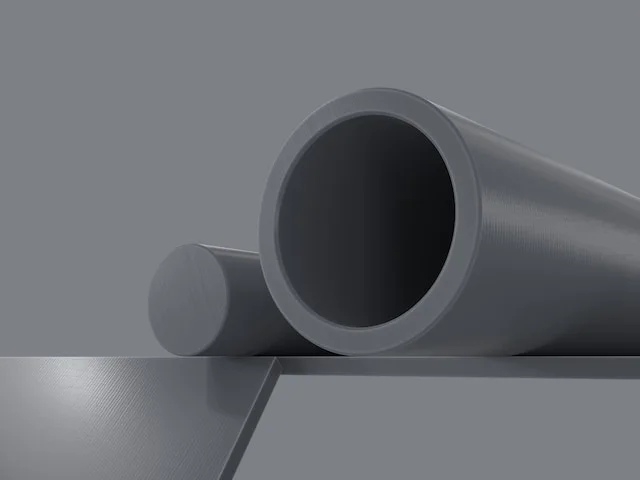

UHMWPE Sheets areoften suited for the lining of chutes as well as hoppers. Their task is to protect the metal

surfaces and keep the solid materials moving slowly. These are suited for the manufacturing of hydraulicbearings and

seals. The provided sheets are apt to perform the medium mechanical duties in water, pneumatics, oil hydraulics, and

unlubricated applications. UHMWPE Sheets are accessible with the good abrasion resistance and are suited to be kept

on the soft mating surfaces.These sheets also boast ofexcellent waterproof capabilities and high abrasion

resistance.

UHMW-PE is specified as polyethylene whose molecular weight is 3.1 million or greater. When making this resolution,

it was located that physical residential or commercial properties raised rapidly as lower MW worths boosted, and

after that leveled off at the 3,100,000 worth. Just like a lot of high-performance polymers, handling of UHMW-PE is

not easy. Because of its high thaw thickness, traditional molding as well as extrusion procedures would break the

long molecular chains that offer the product its superb homes. Existing production approaches include compression

molding, ram extrusion and also warm creating of extruded slugs. UHMW-PE has superior abrasion resistance as well as

an exceptionally low coefficient of rubbing. Effect stamina is high as well as chemical resistance is exceptional.

The material does not barge in impact toughness examinations using standard scratched samplings; double-notched

specimens damage at 20 ft-lb/in (42.1 kJ/m2). UHMW-PE has a crystalline melting point of 267 ° F( 131 ° C). Advised

optimal solution has to do with 200 ° F (93 ° C). Care ought to be taken when attaching UHMW-PE, as its big thermal

development can create the product to bend in between bolts if they are also far apart.