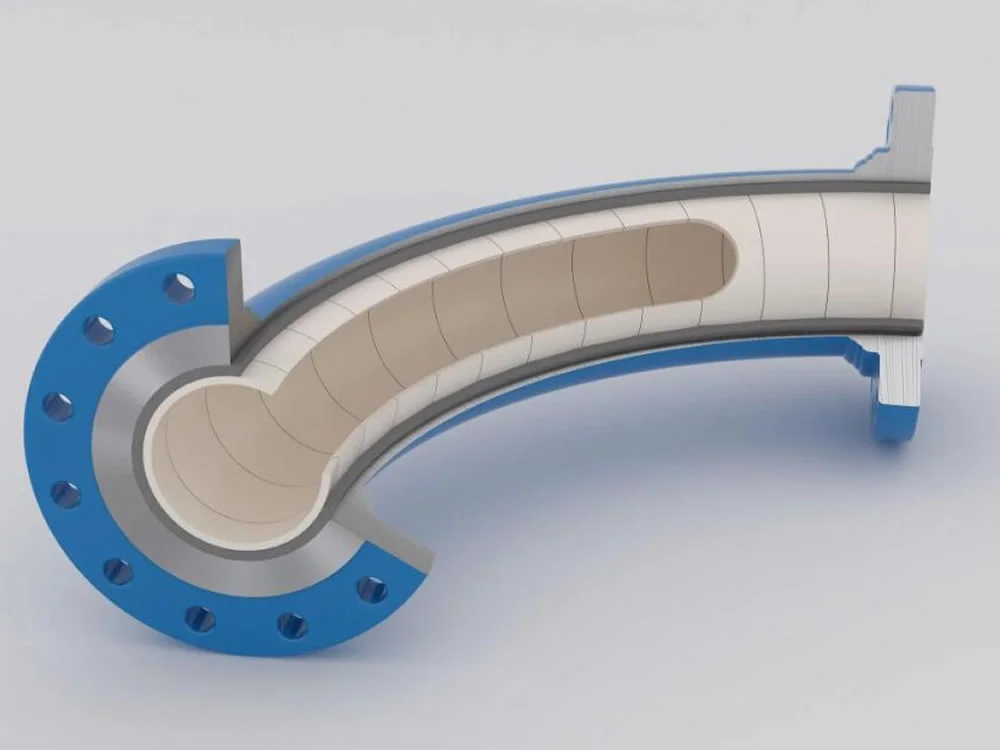

Boiler tube erosion shields, also known as anti-wear shields or tube protection plates, are essential components used to protect boiler tubes in high-temperature, high-pressure systems such as fossil fuel-fired boilers, circulating fluidized bed (CFB) boilers, and waste-to-energy units. These shields are typically installed on the windward side of the tube where flue gas velocity and abrasive particles cause the most severe damage.

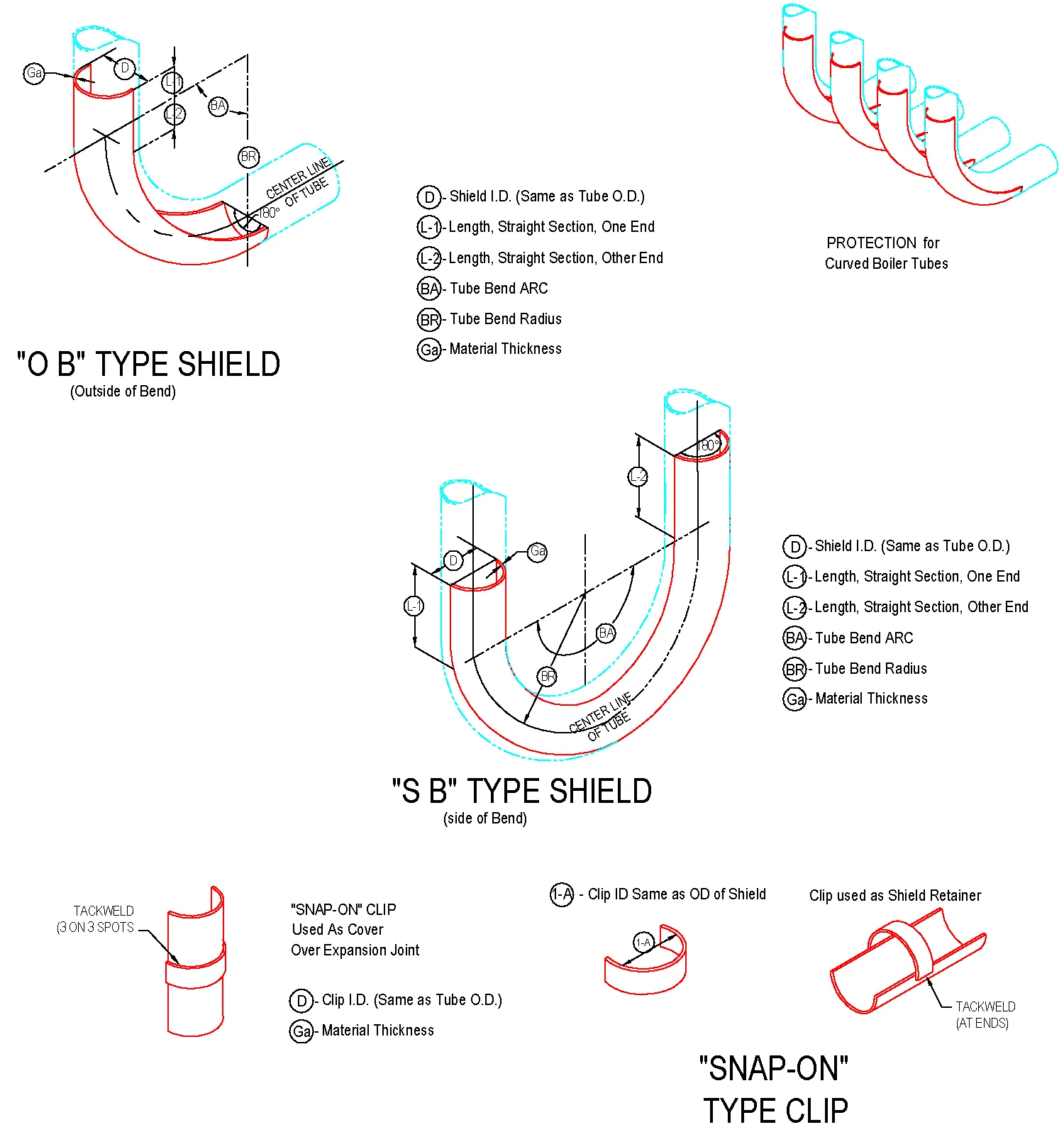

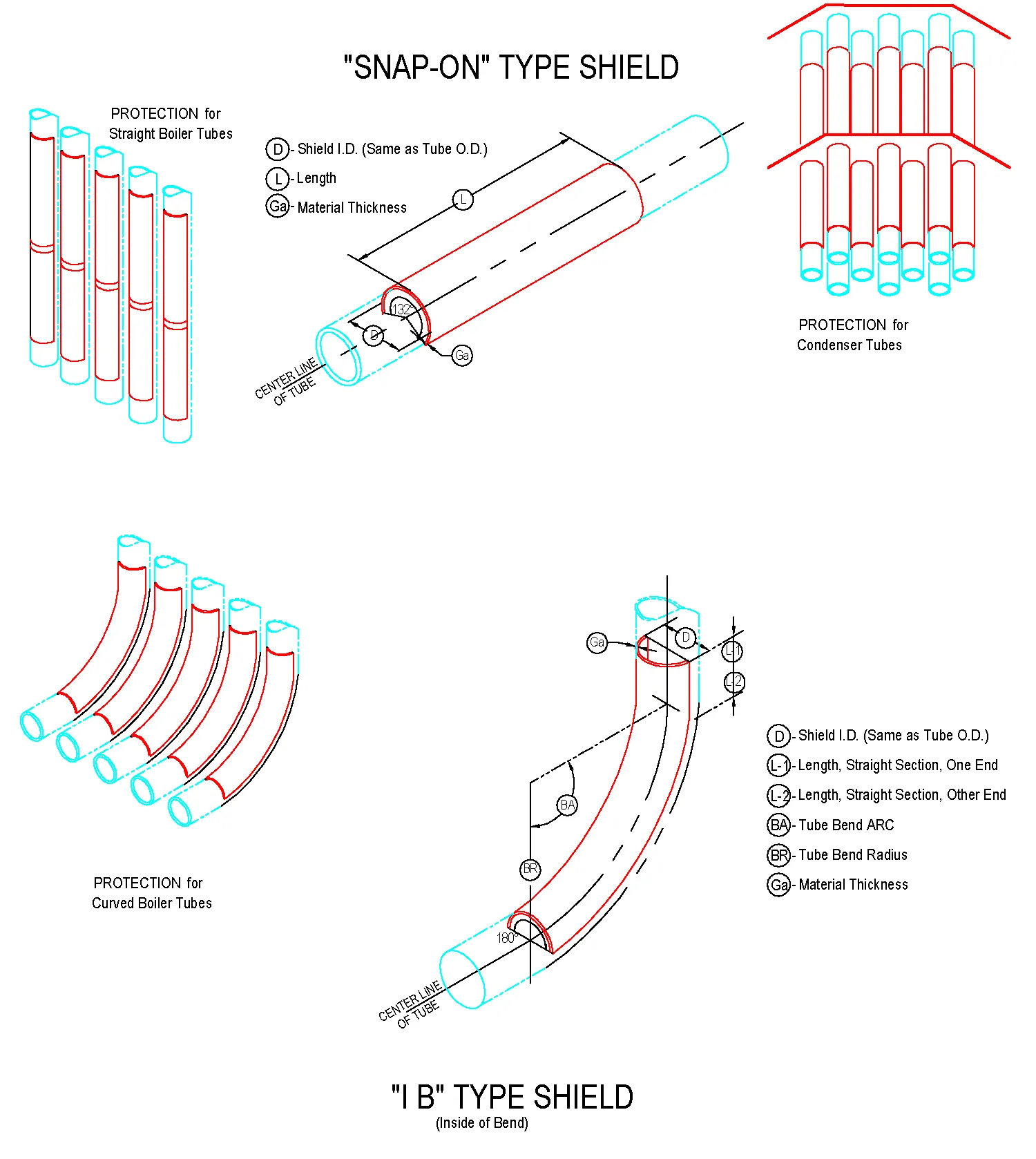

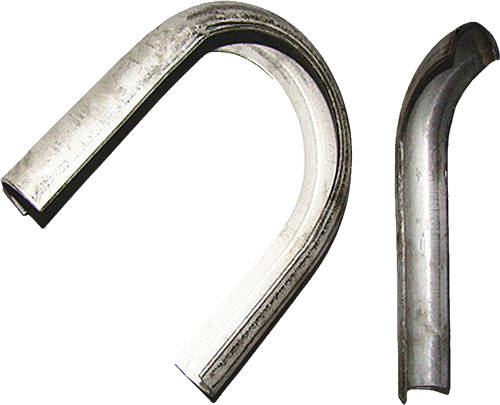

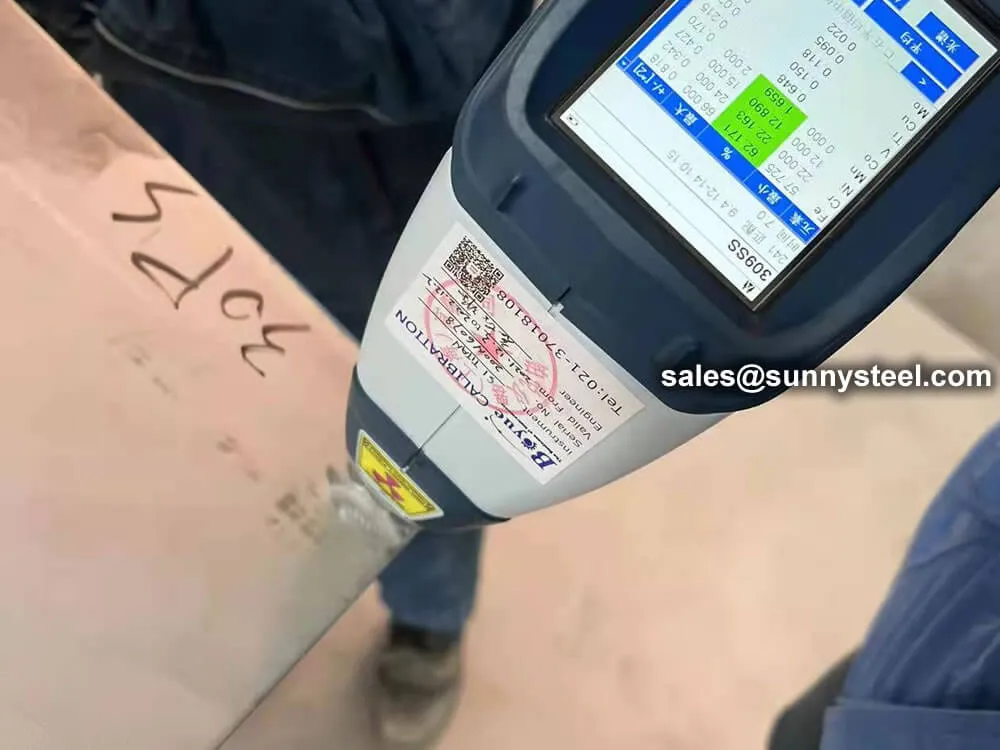

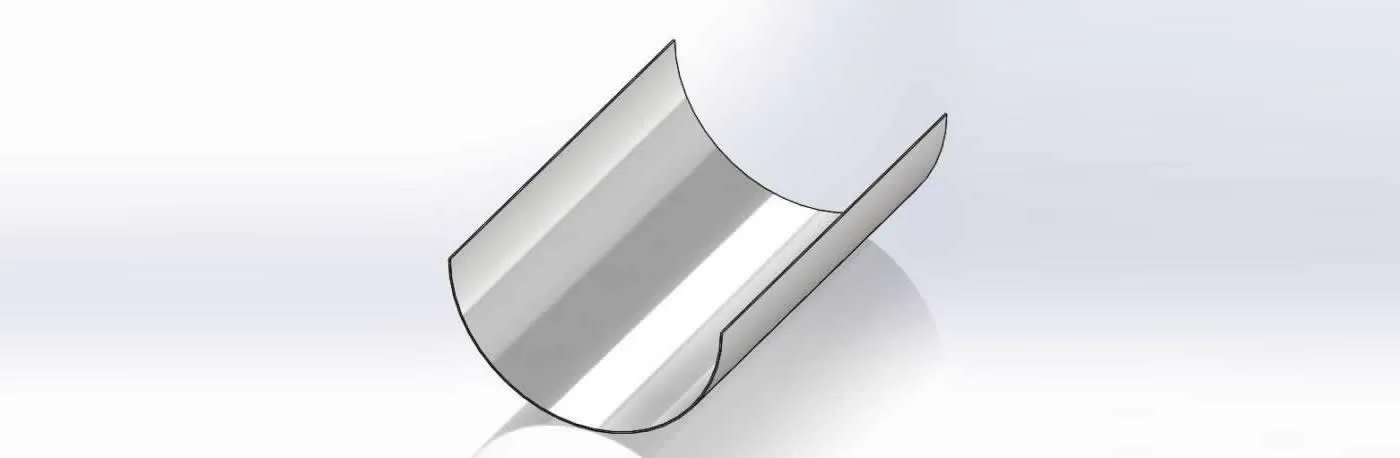

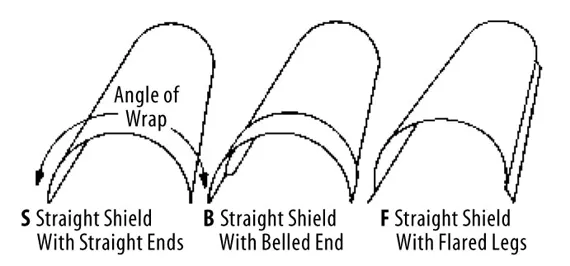

Manufactured from high-grade stainless steels (e.g., SS304, SS316, TP321) or high-temperature alloys like Inconel, these shields offer excellent resistance to erosion, corrosion, and thermal stress. The shields are precision-formed to match tube profiles including straight, U-shaped, L-shaped, and curved segments such as in-curve, outer-curve, and s-curve. Typical outer diameters range from 32mm to 89mm, with shield thicknesses from 2mm to 5mm depending on service severity.

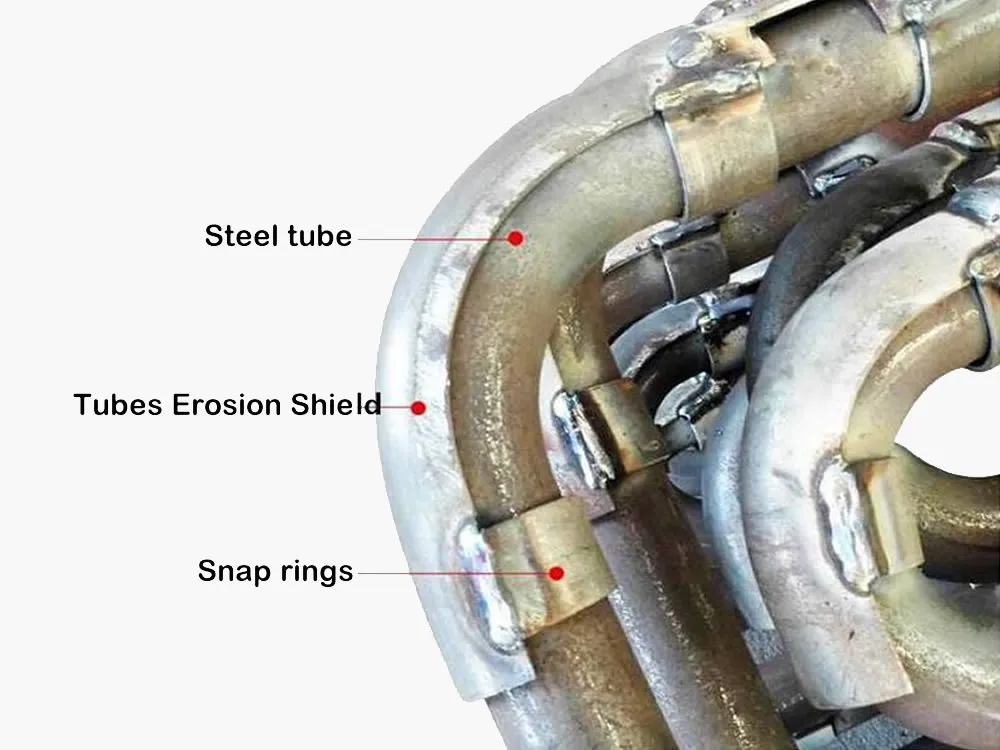

Erosion shields extend the operational life of boiler tubes by forming a durable, impact-resistant barrier. They are spot-welded or clamped directly to the tube surface, preventing thinning, puncturing, and premature failure caused by abrasive flue gases or sootblowing. Service life averages 3–5 years and aligns with common boiler overhaul intervals.

Key Features

- Resistance to erosion, corrosion, and high temperature

- Precision fit for OD 32–89mm tubes

- Available in 180°, 120–160°, or custom arc profiles

- Manufactured via high-pressure pressing for uniform surface finish

- Welded, clamped, or snap-fit installation options

Material Options

- SS304, SS316, TP321 (Cr18Ni9Ti)

- TP309S (Cr23Ni13), TP310S (Cr25Ni20)

- 1Cr13, 1Cr6Si2Mo for 600°C resistance

- Optional chromium carbide coatings for enhanced surface durability

Boiler tube erosion shields are widely applied in power plants, petrochemical facilities, biomass boilers, and industrial furnaces—anywhere high-velocity flue gas or abrasive particles compromise tube integrity. In CFB boilers in particular, these shields help reduce wear from ash and turbulent gas flows, ensuring safer and longer-lasting boiler operation.

Compared to ceramic coatings or hard-facing welds, erosion shields offer superior flexibility, faster replacement, and cost-effectiveness. Regular inspections during maintenance cycles allow damaged shields to be replaced easily, preventing catastrophic failures and reducing operational downtime.