Advantages of Tube Erosion Shields

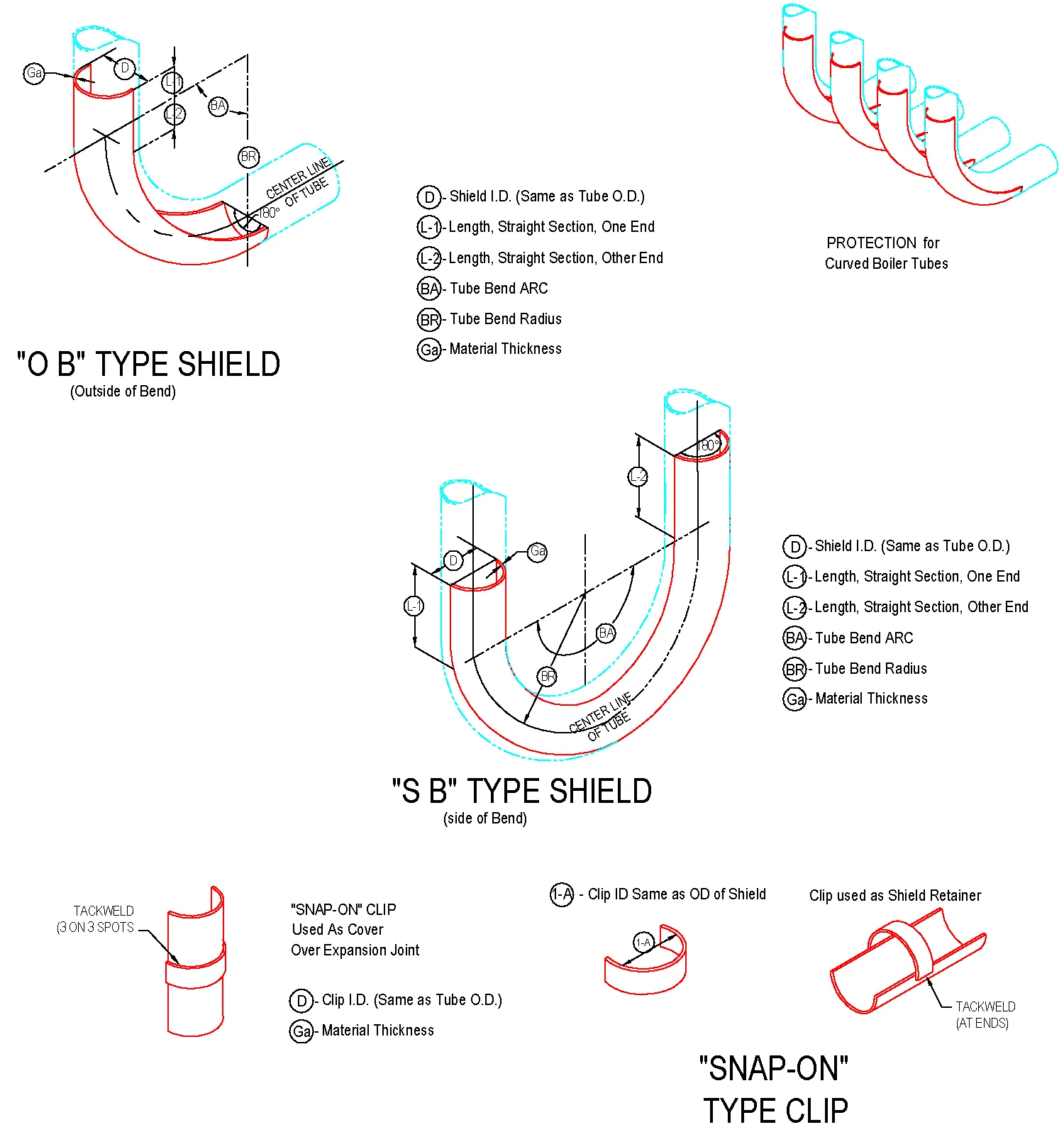

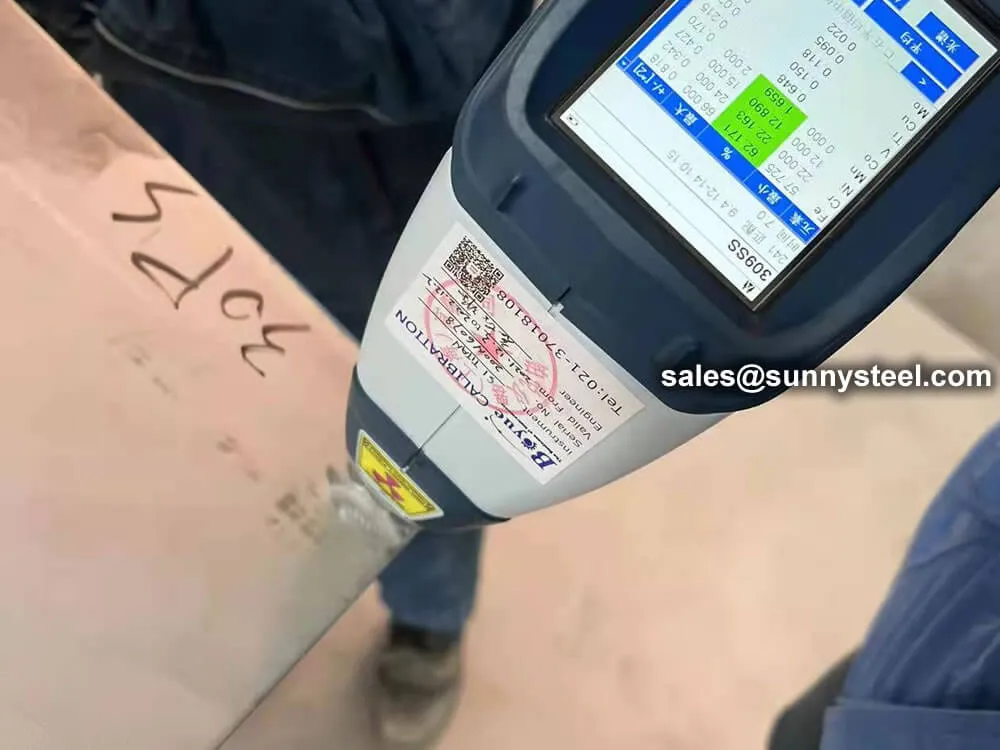

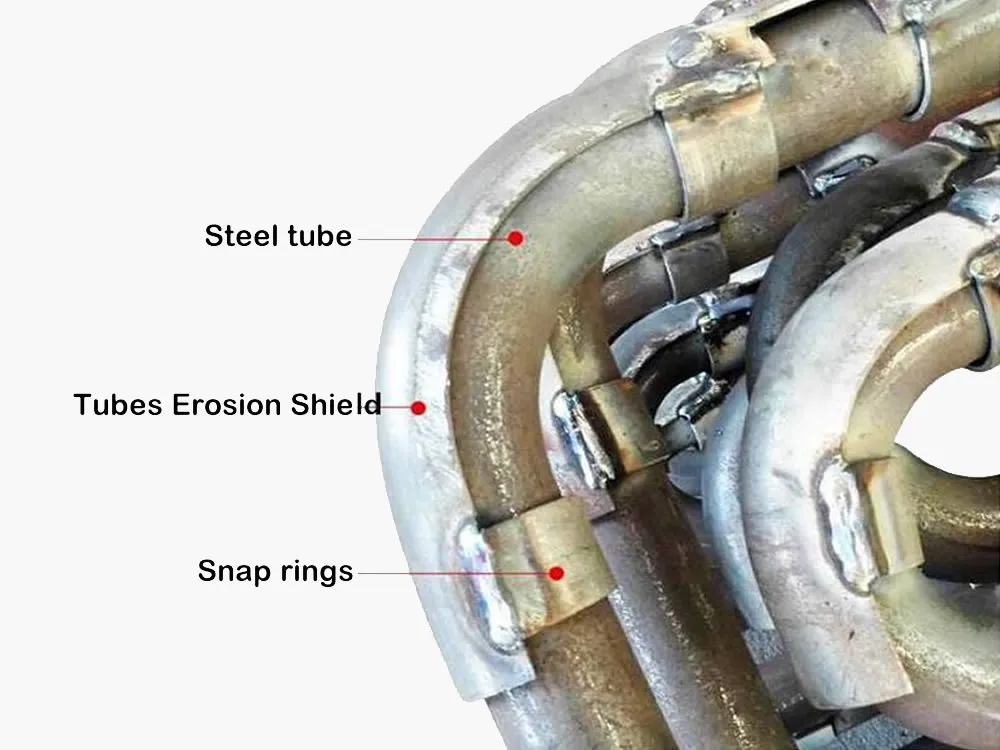

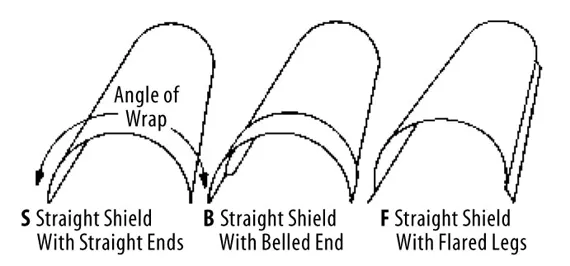

Tube erosion shields are precision-engineered to fit straight sections, tube bends, finned pipes,

and other complex geometries, providing long-term protection in high-wear boiler zones.

Also known as anti-wear plates, anti-corrosion shields, boiler tube protection covers, or snap-on

climbing plates, these components are typically paired with snap rings to ensure

firm and efficient installation on boiler surfaces.

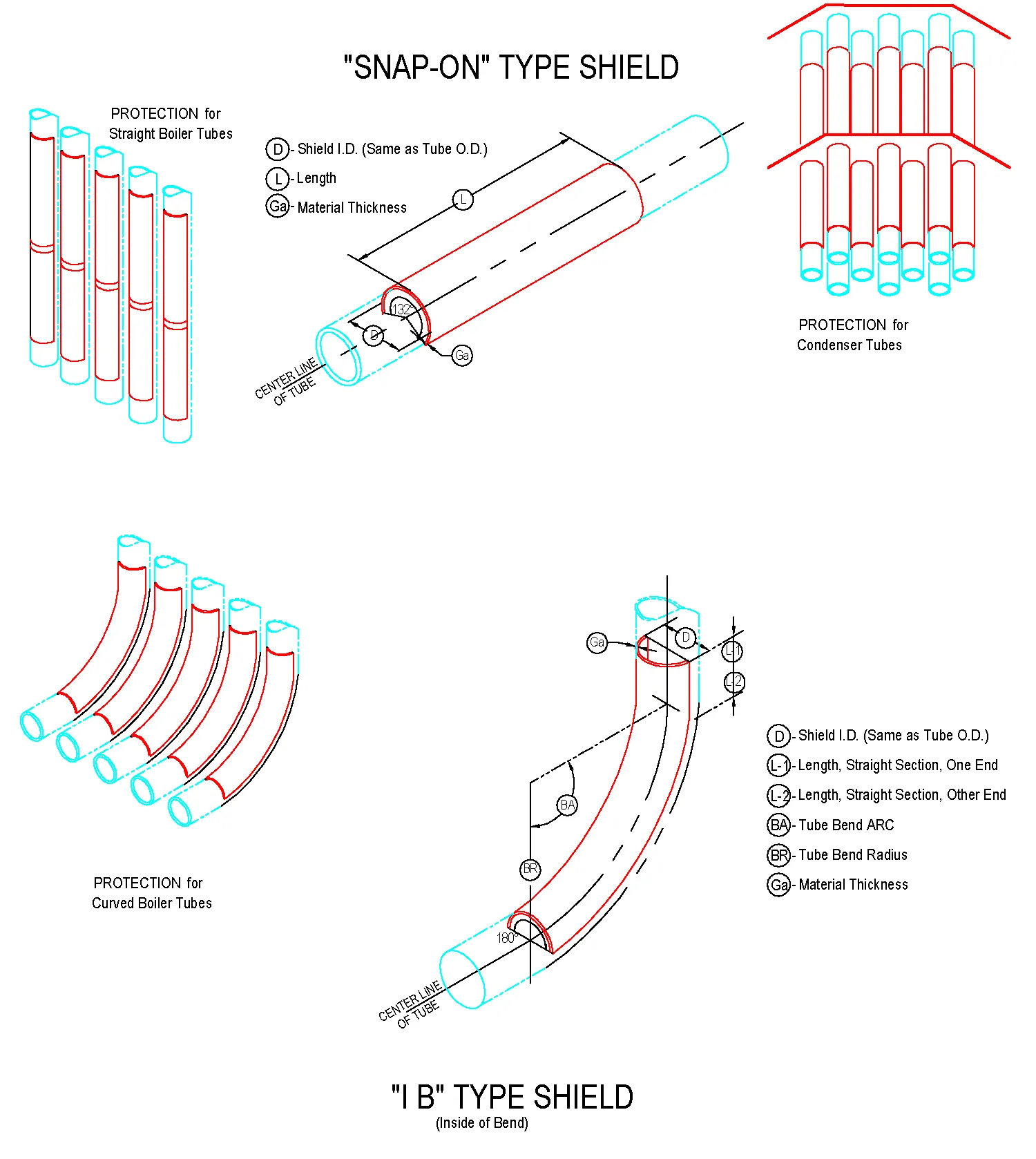

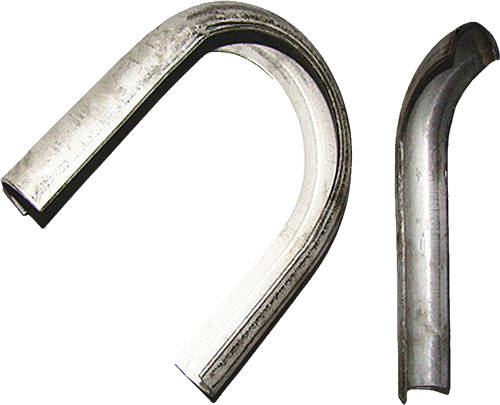

Each erosion shield is manufactured using a high-pressure pressing process with precision moulds.

The result is a smooth surface finish, excellent weldability, and strong attachment performance

without risk of separation under thermal stress.

Curved tube shields are shaped using custom tube benders or formed under pressure, making them ideal

for use in elbows, U-bends, and complex heat exchanger tube paths. The shields effectively absorb

erosive wear from sootblowers, high-speed flue gas, and abrasive particles.

By preventing localized thinning and cracking, these shields significantly reduce boiler downtime,

extend tube life, and lower maintenance costs, especially in CFB boilers, waste heat recovery

systems, and coal-fired power plants.