High-temperature Erosion Shields Made From 310s Stainless Steel To Protect Boiler Tubes From Flue Gas, Slag, And Particle Wear.

310s erosion shields safeguard steam boiler tubes from erosion and oxidation in high-heat zones, enhancing durability and operational safety in power plants.

High-temperature Erosion Shields Made From 310s Stainless Steel To Protect Boiler Tubes From Flue Gas, Slag, And Particle Wear.

310s erosion shields safeguard steam boiler tubes from erosion and oxidation in high-heat zones, enhancing durability and operational safety in power plants.

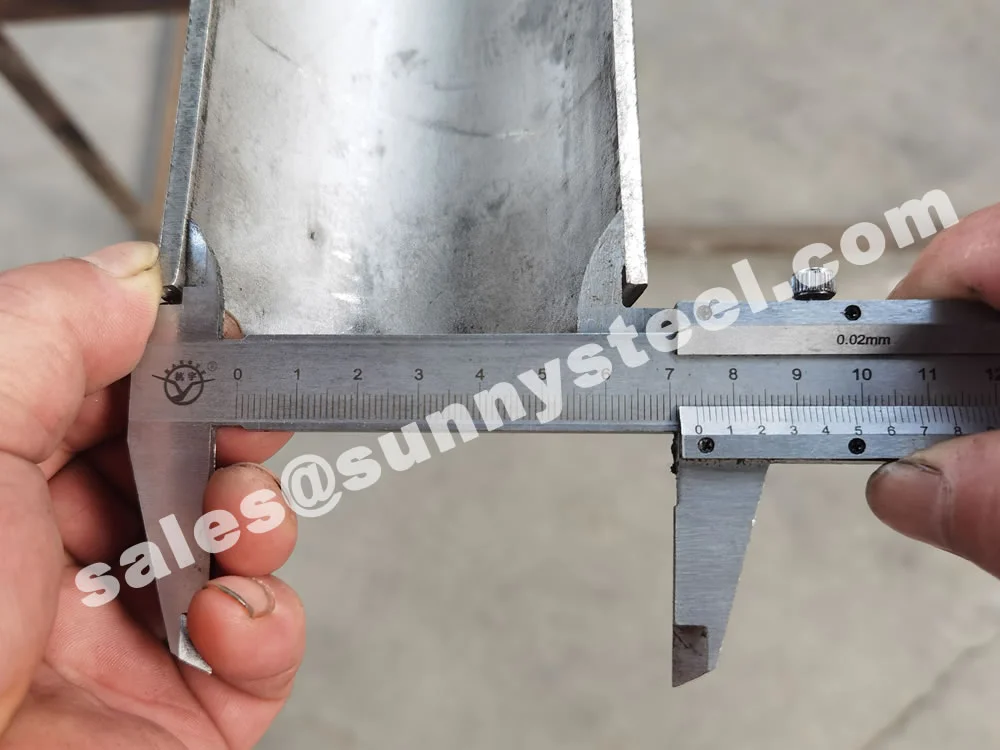

310S stainless steel steam boiler tube erosion shields are premium-grade protection components designed to shield critical areas of boiler tubes from erosion, abrasion, and high-temperature oxidation. These shields are fabricated using AISI 310S, a high-performance, heat-resistant stainless steel known for its superior resistance to scaling, thermal fatigue, and aggressive gas corrosion at temperatures up to 1100°C (2012°F).

In modern steam boilers, erosion commonly occurs where flue gas velocity is highest—such as at bends, tube crossings, and slag-impact zones. Without proper shielding, boiler tubes in these locations suffer wall thinning, resulting in leaks, failures, and unplanned shutdowns.

Installing 310S stainless erosion shields is a proven, economical solution to extend tube life, enhance boiler reliability, and reduce maintenance costs. These shields are especially effective in harsh environments with high temperature and particulate flow, ensuring long-term protection for superheaters, reheaters, and water-cooled wall tubes.

310S stainless steel steam boiler tube erosion shields are precision components made from SS310S material, offering superior protection to boiler tubes from high-temperature corrosion, flue gas erosion, and mechanical wear. These shields are widely used in power generation, waste heat recovery units, and high-temperature industrial furnaces.

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

|---|---|---|---|---|---|---|---|---|---|

| SS 310 | 0.015 max | 2.0 max | 0.15 max | 0.020 max | 0.015 max | 24.00 – 26.00 | 0.10 max | 19.00 – 21.00 | 54.7 min |

| SS 310S | 0.08 max | 2.0 max | 1.00 max | 0.045 max | 0.030 max | 24.00 – 26.00 | 0.75 max | 19.00 – 21.00 | 53.095 min |

| Standard | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| SS 310 | 1.4841 | S31000 | SUS 310 | 310S24 | 20Ch25N20S2 | - | X15CrNi25-20 |

| SS 310S | 1.4845 | S31008 | SUS 310S | 310S16 | 20Ch23N18 | - | X8CrNi25-21 |

| Item | UNS | ASTM | ASME | AMS |

|---|---|---|---|---|

| 310 | S31000 | ASTM A240 | ASME SA240 | AMS 5521 |

| 310S | S31008 | ASTM A240 | ASME SA240 | AMS 5521 |

| 310H | S31009 | ASTM A240 | ASME SA240 | AMS 5521 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%) | Elongation |

|---|---|---|---|---|

| 7.9 g/cm³ | 1402°C (2555°F) | 75000 psi / 515 MPa | 30000 psi / 205 MPa | 40% |

Stainless steel 310S tube shields are commonly installed on boiler components such as superheaters, reheaters, and economizers. Their high Cr-Ni composition provides long-term service performance in aggressive heat and chemical environments, reducing the need for frequent maintenance and extending operational uptime.

Ss 309 shields protect boiler tubes from erosion a...

Q235 tube shields offer reliable and economical er...

1cr18ni9ti tube shields offer excellent resistance...

316 stainless steel tube shields protect boiler tu...

1cr20ni14si2 tube shields offer superior resistanc...