High-temperature Protection For Curved Boiler Sections

Ss316 tube shields are precision-formed to protect bended boiler and exchanger tubes from corrosion, heat, and erosion.

High-temperature Protection For Curved Boiler Sections

Ss316 tube shields are precision-formed to protect bended boiler and exchanger tubes from corrosion, heat, and erosion. ideal for high-moisture, acidic, or chloride environments.

SS316 Shields for Bended Tubes are specially manufactured stainless steel sleeves designed to fit and protect curved sections of boiler tubes, economizer bends, and superheater elbows. Made from SS316 (UNS S31600), these shields offer superior resistance to:

Thanks to the molybdenum content in SS316, it outperforms 304 and 1Cr13 materials in resisting localized corrosion, making it ideal for marine boilers, chemical recovery boilers, and wet-side flue gas bends.

| Application Area | Risk Factor | SS316 Benefit |

|---|---|---|

| Economizer Return Bends | Moisture, Ash, Sulfates | Excellent wet corrosion resistance |

| Superheater Elbows | High-Temp + Acid Vapor | Anti-scaling and pitting prevention |

| Flue Gas Turns | Flue dust + temperature flux | Maintains integrity under thermal cycles |

| Marine Exhaust Curves | Saltwater vapors | Chloride pitting resistance |

| Waste Heat Tube Bends | Corrosive gases + pressure | Durable under combined stress |

| Property | Specification |

|---|---|

| Material Grade | SS316 (UNS S31600) / SS316L (UNS S31603) |

| Form | U-type, half-shell, or full wrap curved |

| Thickness | 1.5 mm – 2.5 mm |

| Radius Compatibility | As per drawing/sample tube curvature |

| Surface Finish | Pickled / Passivated / Polished |

| Attachment Method | Spot welded / Band clamp / Screw-fastened |

316/316L stainless steel is widely used in chloride and chemical process environments due to its enhanced resistance to corrosion and pitting, attributed to its molybdenum content. These alloys offer excellent mechanical and corrosion-resistant properties across a range of temperatures and environments, making them essential in chemical processing, marine, and high-temperature industrial applications.

Low carbon version of 316, offering superior resistance to intergranular corrosion after welding. Commonly used in marine and chloride-rich environments. Excellent weldability without post-weld annealing.

High carbon content variant suitable for elevated temperature service. Offers greater short and long-term creep strength. Commonly used in high-stress boiler or furnace applications.

Standard molybdenum-bearing austenitic stainless steel. Excellent resistance to chlorides and moderate acids. Widely used across various chemical and process industries.

| Grade | 316 | 316L |

|---|---|---|

| UNS | S31600 | S31603 |

| Carbon (C) Max. | 0.08 | 0.030 |

| Manganese (Mn) Max. | 2.00 | 2.00 |

| Phosphorus (P) Max. | 0.045 | 0.045 |

| Sulfur (S) Max. | 0.030 | 0.030 |

| Silicon (Si) Max. | 1.00 | 1.00 |

| Chromium (Cr) | 16.0–18.0 | 16.0–18.0 |

| Nickel (Ni) | 10.0–14.0 | 10.0–14.0 |

| Molybdenum (Mo) | 2.0–3.0 | 2.0–3.0 |

| Iron (Fe) | Balance | |

Chemical composition details for 316 and 316L stainless steels used in corrosion-resistant applications.

| Material | Form | Tensile Strength (ksi) | Yield Strength (ksi) | Elongation (%) | Hardness (HB) |

|---|---|---|---|---|---|

| Alloy 316L | Sheet AMS 5507 | 100 max | - | 45 | - |

| Alloy 316 | Sheet AMS 5524 | 75 min | 30 | 45 | 207 max |

Typical mechanical properties for 316 and 316L stainless steel sheets used in industrial applications.

| Electrical Resistivity | Magnetic Permeability |

|---|---|

| 7.2e-005 ohm-cm | 1.008 |

| 1.16e-004 at 650°C | RT |

Electrical resistivity and magnetic permeability values at room and elevated temperatures.

| Alloy | UNS | Tensile (MPa) | Yield (MPa) | Elongation (%) | Hardness |

|---|---|---|---|---|---|

| 316 | S31600 | 515 | 205 | 35 | 90 Rb |

| 316L | S31603 | 485 | 170 | - | 90 Rb |

Physical and mechanical properties comparison for 316 and 316L stainless steels.

316L is preferred when welding thick sections is necessary and when resistance to intergranular corrosion is critical. 316H is used for elevated temperature pressure services.

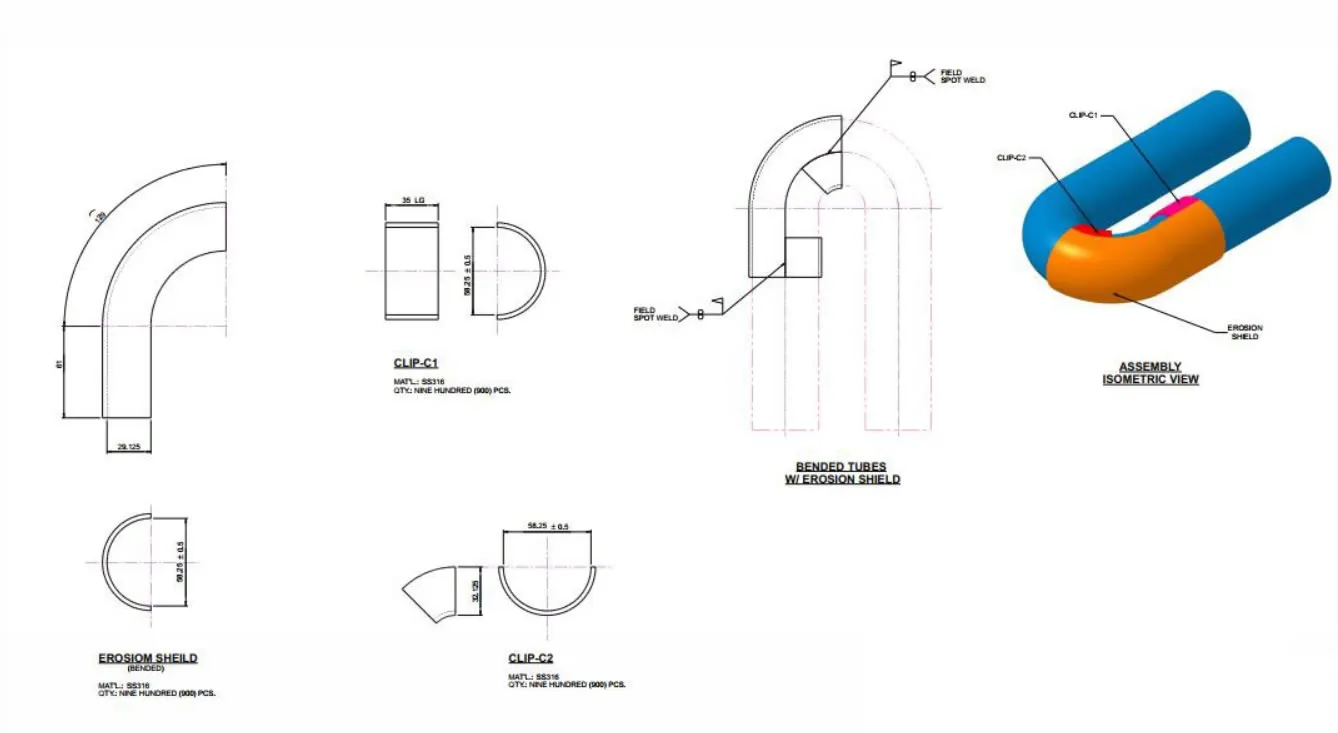

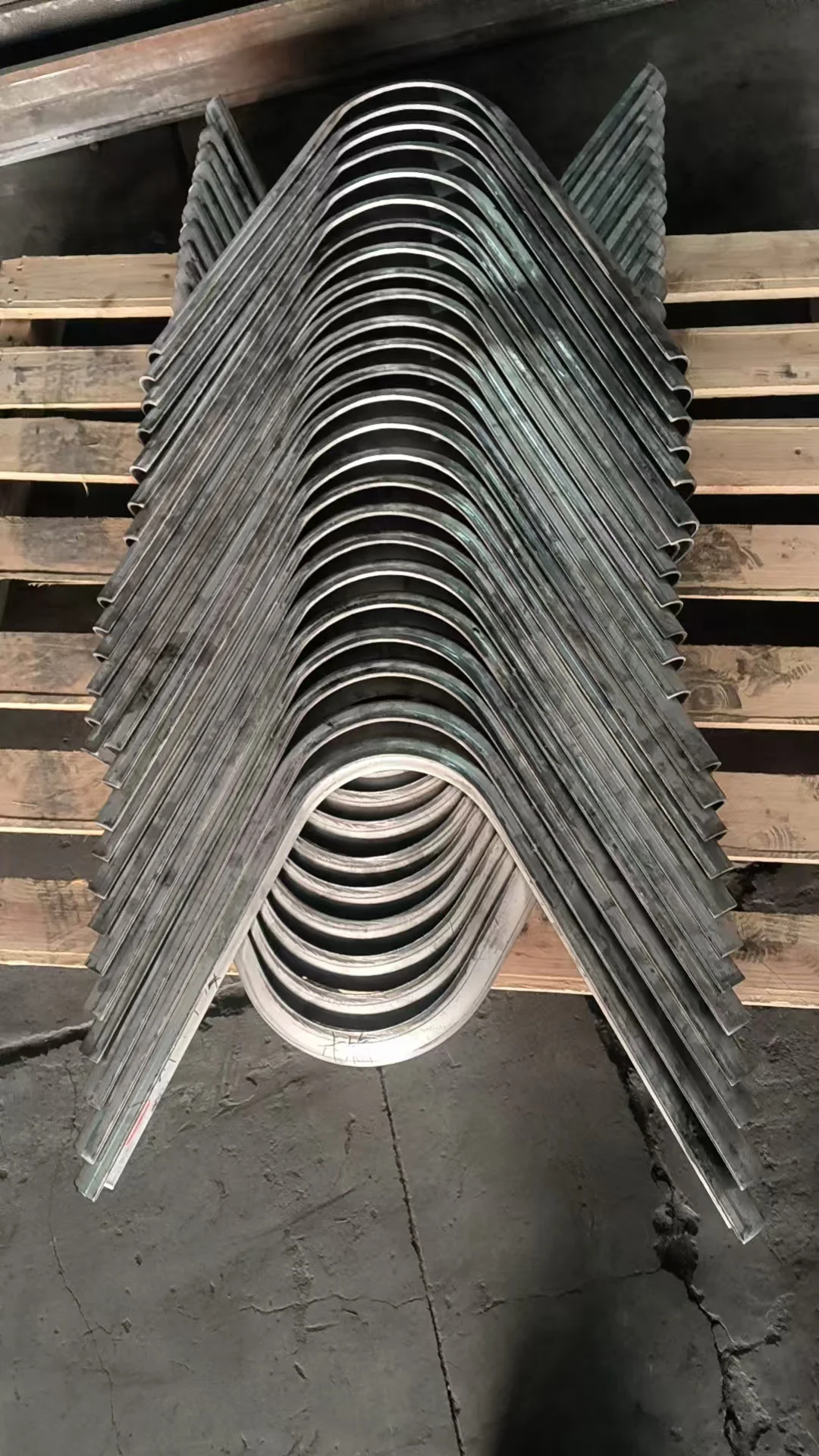

Manufactured to exacting standards using high-pressure pressing technology

Advanced equipment and precision moulds ensure optimal welding performance, smooth surfaces, and rapid turnaround times [[2, 5]].

Arc-shaped wear-resistant tiles are formed using specialized moulds on high-pressure presses or pipe benders [[2, 9]].

This process delivers:

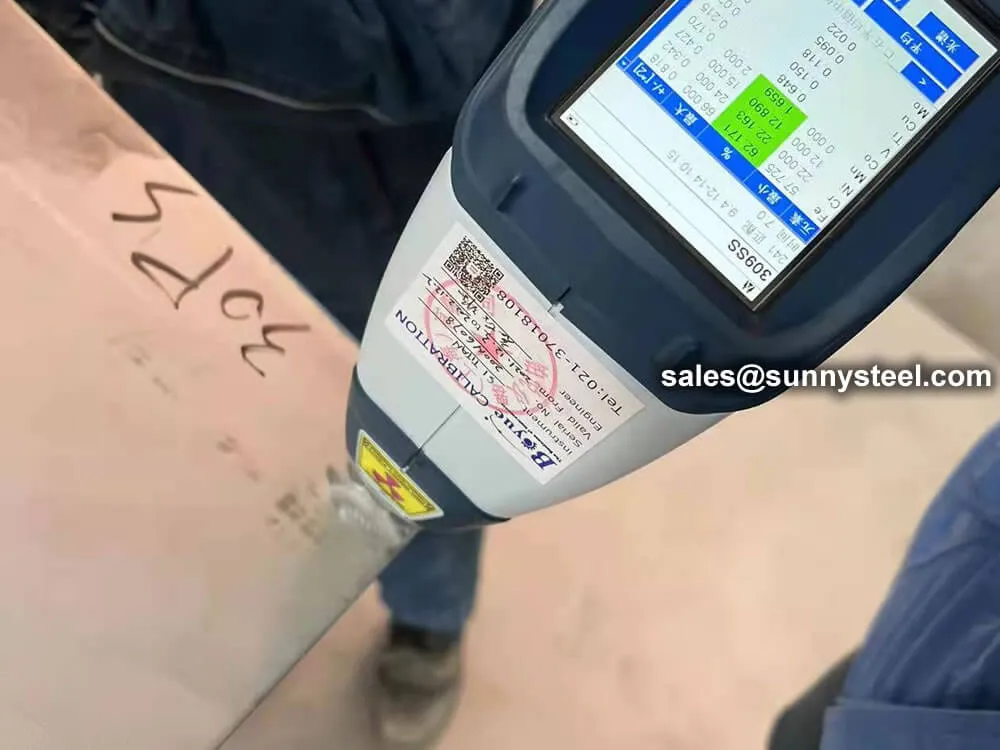

Positive Material Identification (PMI) testing verifies stainless steel composition before production, ensuring compliance with API 578 standards [[1, 3]].

Raw materials are sourced directly from certified steel mills with Mill Test Certificates (MTC). Excess material is repurposed into snap rings for zero-waste manufacturing [[5, 15]].

Explore detailed material grades, dimensional standards, and configuration types for stainless steel tube shields used in high-temperature boiler environments.

Boiler tube erosion shields are manufactured using heat- and corrosion-resistant alloys for superior durability in demanding thermal systems such as superheaters, economizers, and reheaters.

| Material Grade | Operating Temp | Chromium (%) | Nickel (%) | Typical Application |

|---|---|---|---|---|

| SS 304 | Up to 600°C | 18% | 8% | General boiler protection |

| SS 316 | Up to 650°C | 16–18% | 10–14% | Corrosive steam systems |

| SS 309 | Up to 750°C | 22–24% | 12–15% | High-temp gas zones |

| SS 310S | Up to 1000°C | 24–26% | 19–22% | Extreme flue gas exposure |

| SS 310 | Up to 1200°C | 24–26% | 19–22% | Aggressive chemical plants |

| Carbon Steel | Up to 1400°C | 26–28% | 22–25% | High-temperature gas systems |

| Inconel 600 | Up to 1200°C | 15% | 72% | Aggressive chemical plants |

Tube erosion shields are precision-engineered to match a wide range of pipe diameters and curvature profiles, ensuring exact fit and reliable performance in erosive gas flows.

| Specification | Standard Range | Common Sizes | Customization |

|---|---|---|---|

| Tube Outer Diameter | 32–89mm | 38, 42, 48, 51, 57, 63.5, 76mm | Other diameters available |

| Shield Length | 20–3000mm | 1000–2000mm | As per project requirement |

| Shield Thickness | 2–5mm | 3mm, 4mm | Based on wear conditions |

| Coverage Angle | 120°–240° | 180° (Semi-circular) | Tailored arcs for complex bends |

| Shield Clearance | 1–3mm | 2mm typical | For thermal expansion fit |

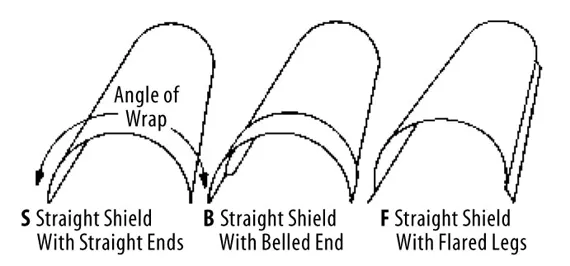

Tube erosion shields are precision-engineered to fit straight sections, tube bends, finned pipes, and other complex geometries, providing long-term protection in high-wear boiler zones.

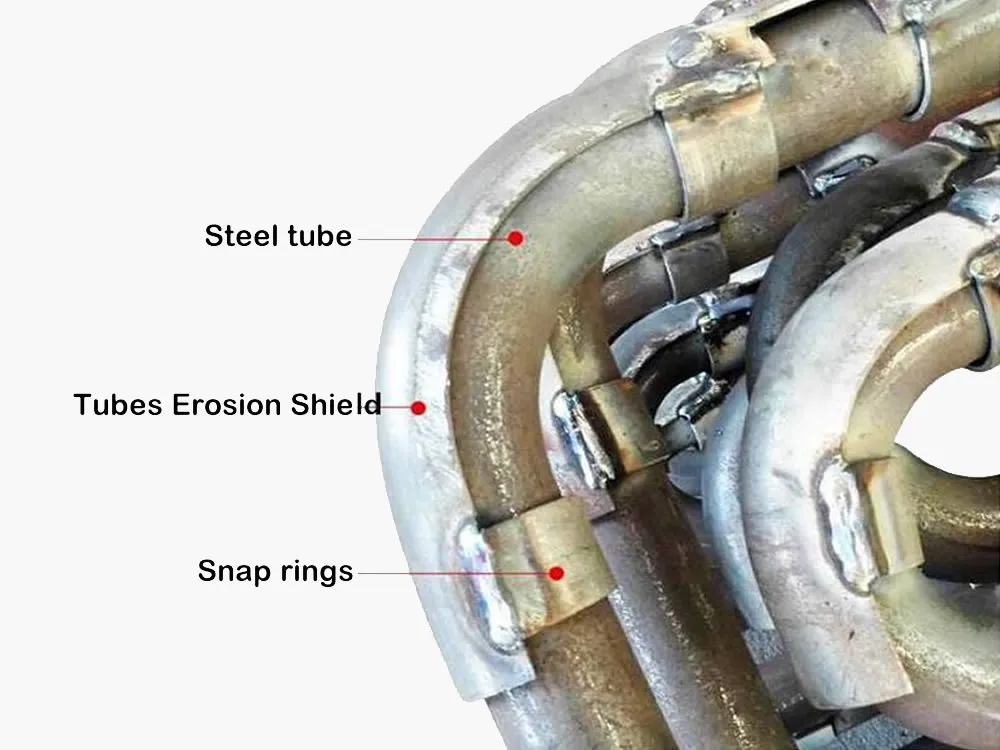

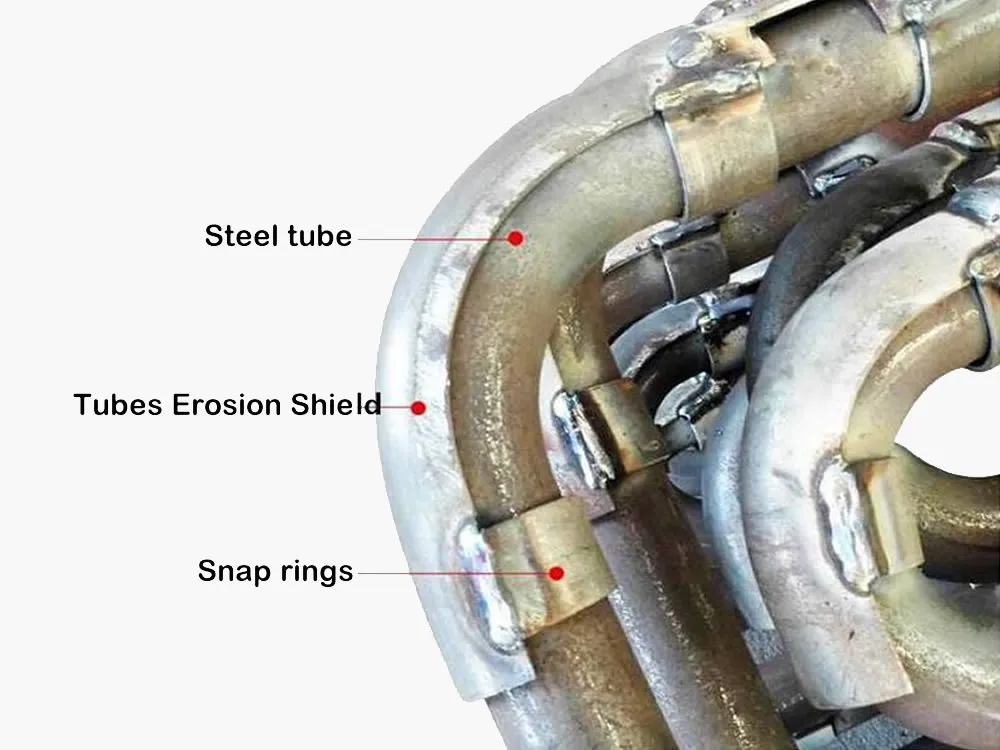

Also known as anti-wear plates, anti-corrosion shields, boiler tube protection covers, or snap-on climbing plates, these components are typically paired with snap rings to ensure firm and efficient installation on boiler surfaces.

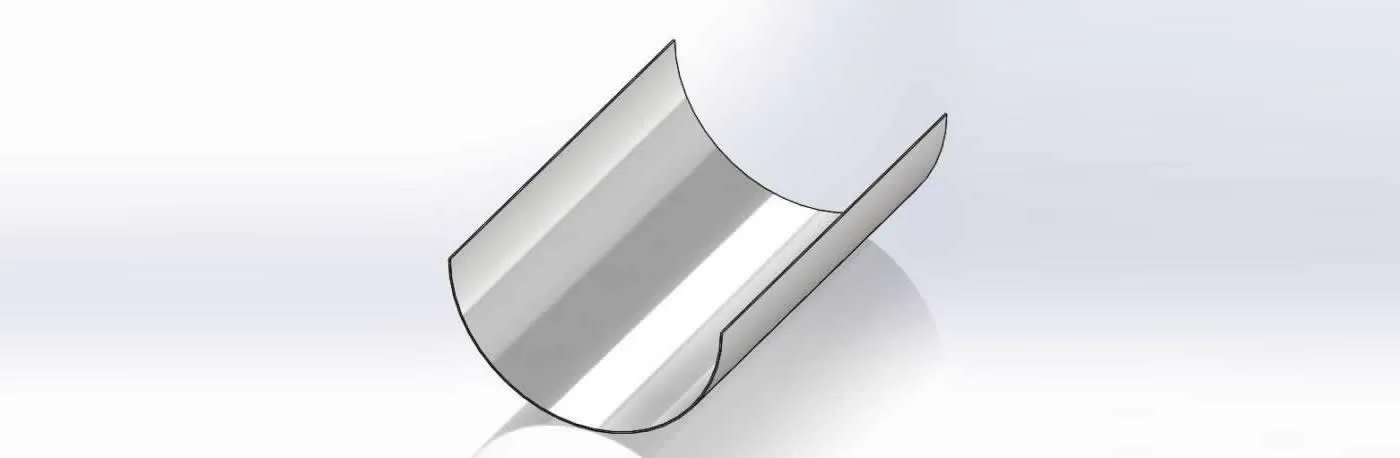

Each erosion shield is manufactured using a high-pressure pressing process with precision moulds. The result is a smooth surface finish, excellent weldability, and strong attachment performance without risk of separation under thermal stress.

Curved tube shields are shaped using custom tube benders or formed under pressure, making them ideal for use in elbows, U-bends, and complex heat exchanger tube paths. The shields effectively absorb erosive wear from sootblowers, high-speed flue gas, and abrasive particles.

By preventing localized thinning and cracking, these shields significantly reduce boiler downtime, extend tube life, and lower maintenance costs, especially in CFB boilers, waste heat recovery systems, and coal-fired power plants.

Proper installation of boiler tube erosion shields is essential for preventing wear, prolonging service life, and avoiding critical failures like boiler explosions.

Erosion shields are installed primarily to protect the heating surfaces of boiler tubes from high-velocity flue gases and abrasive particles. They reduce wear and enhance heat transfer efficiency in high-stress environments such as CFB boilers and waste heat recovery units.

A snap ring is used to affix the erosion shield securely to the tube surface. It typically overlaps the shield slightly—usually with a 190°–200° arc—allowing it to clamp firmly while leaving space for welding. The ring width must be no less than 20mm for adequate support.

Each erosion shield requires 2–4 snap rings spaced at 200–500mm intervals. The rings and shield must be fully spot welded to prevent displacement from thermal expansion and vibrations during operation.

The installation procedure varies slightly for different shapes—straight, curved, or S-type. All joints must be secure, sealed, and aligned to ensure continuous protection without gaps.

Boiler tube erosion shields are typically attached using the following methods:

Yes,

we provide custom straight boiler tube shields based on customer requirements.

These can be tailored in shape, size, and material to suit specific boiler configurations.

Boiler tubes erosion shields protect critical boiler components from wear and corrosion, ensuring durability and efficiency across multiple industries.

Protects boiler tubes in coal-fired, natural gas, biomass, and waste-to-energy plants from abrasive flue gases and high temperatures.

Shields tubes in petrochemical, pulp and paper, food processing, and manufacturing boilers, reducing wear and maintenance costs.

Provides corrosion-resistant protection for marine boiler systems and offshore platform boilers in harsh, corrosive environments.

Enhances tube durability in gas turbine exhausts and industrial process systems, improving energy efficiency and longevity.

Reduces downtime with easy-to-install shields for straight, bent, and finned tubes, ensuring long-term boiler reliability.

Custom shields for unique boiler configurations, protecting against abrasive particles and high-pressure conditions.

| Industry | Application |

|---|---|

| Coal-Fired Power Plants | Protects superheaters, reheaters, and economizers from abrasive ash and flue gas erosion. |

| Natural Gas Combined Cycle | Shields tubes in high-pressure boilers from wear caused by high-velocity gas flows. |

| Biomass Power Stations | Reduces tube wear in boilers handling abrasive biomass materials like wood chips. |

| Waste-to-Energy Plants | Protects tubes from corrosion and erosion in incineration and waste processing systems. |

| Petrochemical Facilities | Ensures durability of boiler tubes in high-temperature, corrosive chemical environments. |

| Pulp and Paper Mills | Shields boiler tubes from wear in steam generation systems for paper production. |

| Food Processing Plants | Protects steam boiler tubes from wear and corrosion in hygienic processing environments. |

| Marine Boiler Systems | Provides corrosion-resistant protection for tubes in harsh marine environments. |

| Offshore Platform Boilers | Ensures tube longevity in remote, corrosive offshore conditions with minimal maintenance. |

| Heat Recovery Steam Generators | Enhances tube life in systems recovering heat from gas turbine exhausts. |

| Industrial Process Exhausts | Protects tubes in waste heat recovery systems handling variable, abrasive exhausts. |

The service life of boiler tube erosion shields varies depending on boiler type and installation location.

Normally, shields last throughout one overhaul cycle (3–5 years). During major maintenance, shields are inspected and replaced if:

In sections such as superheaters and economizers, erosion shields are placed on the flue gas flow-facing side of the tubes to protect against high-temperature abrasion. Curved shields are essential for elbows and U-bends to prevent wear in circulating fluidized bed (CFB) boilers, where demand is increasing.

Outside-of-bend tube shields offer robust protecti...

Bend tube shields are curved protective sleeves th...

Inside-of-bend tube shields protect the internal c...

U-type outer half-round tube shields offer robust ...

Custom straight tube shields are designed for boil...