Segmented Protection For High-wear Zones

Comb-shaped boiler tube shields offer modular, segmented protection for high-wear zones, reducing erosion and thermal stress in critical boiler areas with precision-engineered steel sleeves.

Segmented Protection For High-wear Zones

Comb-shaped boiler tube shields offer modular, segmented protection for high-wear zones, reducing erosion and thermal stress in critical boiler areas with precision-engineered steel sleeves.

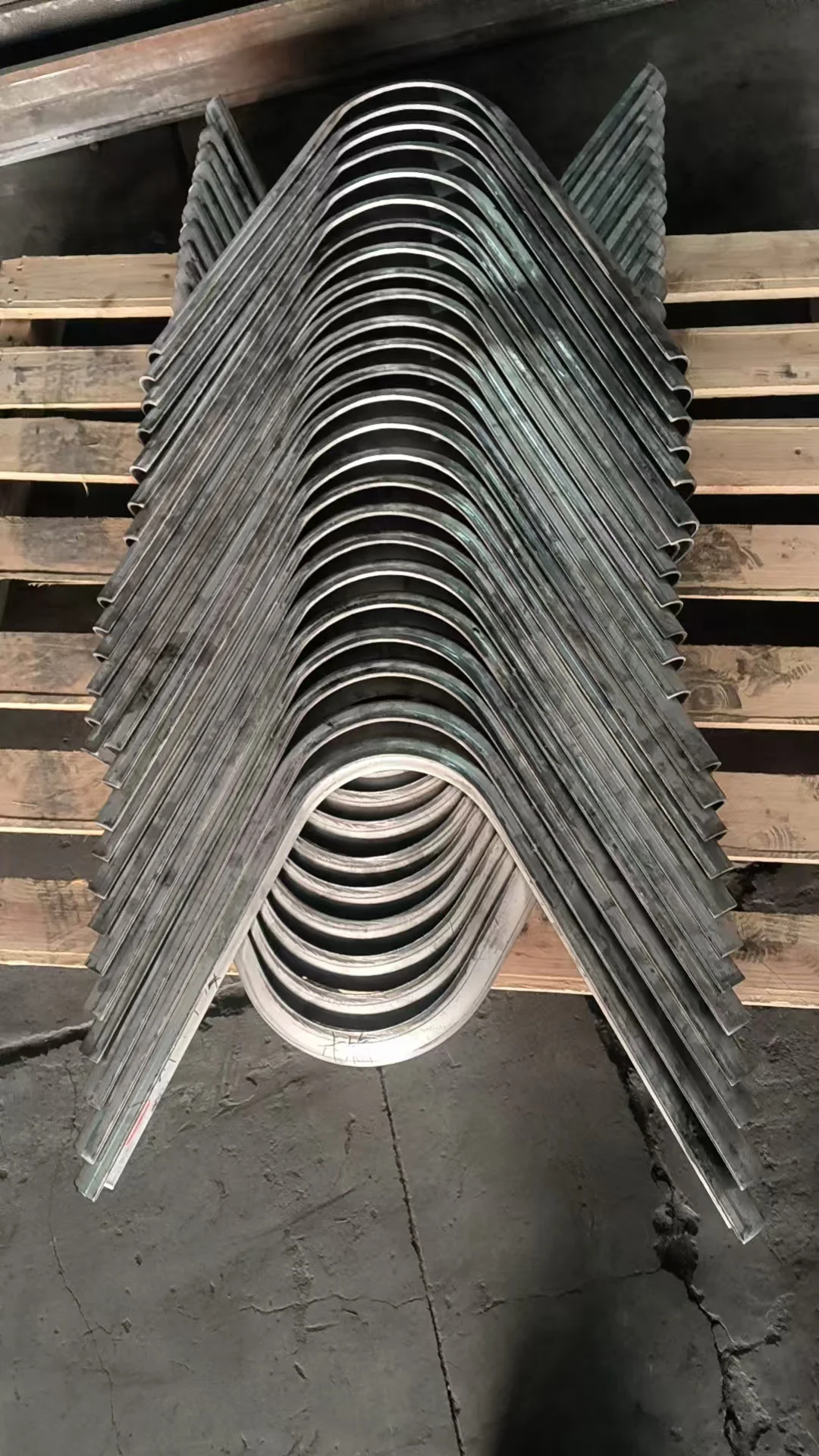

Comb-Shaped Boiler Tube Shields are modular, interlocking sleeves designed to protect critical boiler tube zones from intense erosion, thermal cycling, and mechanical impact. Unlike standard full-wrap shields, comb-type shields are segmented — resembling comb teeth — which allows them to expand and flex with the tube’s thermal movement, reducing stress cracking and surface delamination.

These shields are especially useful for:

Crafted from stainless steels (304, 316, 310S) or heat-resistant alloys (Cr25Ni20, Inconel), they provide superior corrosion resistance and mechanical durability under high flue gas velocity and extreme temperature conditions.

| Boiler Section | Problem Type | Recommended Material |

|---|---|---|

| Sootblower lanes | Particle impact + thermal fatigue | 310S / Cr25Ni20 |

| Water wall corners | Ash erosion + moisture | 316L / 1Cr13 |

| Cyclone inlet bends | Flue gas turbulence | Inconel / Duplex |

| Superheater risers | High-temperature oxidation | 310S / 304H |

| Waste-to-energy walls | Corrosive flue gas attack | SS316L / Hastelloy |

| Property | Specification |

|---|---|

| Structure Type | Segmented (Comb-style Interlock) |

| Material Options | 304, 316, 310S, 1Cr13, Cr25Ni20, Inconel |

| Shield Thickness | 1.5 mm – 2.5 mm |

| Segment Length | 80 mm – 150 mm per tooth |

| Mounting Method | Spot welding / partial wrap / clamp mount |

| Surface Finishing | Pickled / Shot Blasted / Anti-scaling Coated |

Outside-of-bend tube shields offer robust protecti...

Bend tube shields are curved protective sleeves th...

Inside-of-bend tube shields protect the internal c...

U-type outer half-round tube shields offer robust ...

Custom straight tube shields are designed for boil...