These systems consist of two key components:

-

Inner wear-resistant tube – typically lined with ceramic, UHMWPE, or bimetallic alloy; designed to withstand direct particle abrasion and chemical attack.

-

Outer structural pipe – generally made of carbon steel, providing mechanical strength and pressure containment.

This two-tiered protection strategy dramatically extends service life and minimizes unplanned downtime compared to traditional single-wall pipes.

Double tube systems are particularly effective in industries such as

mining, thermal power, cement, dredging, and

chemical processing, where aggressive media like slurry, ash,

tailings, and chemically active fluids rapidly degrade standard pipelines.

The double tube design accommodates a wide range of sizes and geometries, including straight sections,

elbows, reducers, and T-junctions. Connection options include welding, flanged joints, or quick coupling systems for

ease of field installation and maintenance.

- Wear life of pipage is long. The wear is no problem for more than 30 years below 0.1mm/year by ASTM pipe use by results, and the use of abrasion resistant steel is unnecessary.

- Initial cost and running cost are inexpensive.

- The aerial amount of consumption is little and efficient.

- Even if a system is stopped in the double pipe lines while leaving ash, it’s possible to resume in its state. Then it isn’t necessary to be linear cleaning.

- This system is controlled independently. Stable running is always made of that.

- More than 1000 m of long-distance conveying is possible and with a good record of performance.

Turbulent flow is the irregular and chaotic movement of fluid with rapid changes in velocity and direction. It is typically observed at higher flow rates or in pipes with rough surfaces, resulting in increased mixing and improved heat transfer performance. Turbulent flow is widely used in various engineering applications, such as heat exchangers and certain chemical processes, where efficient heat transfer or fluid mixing is required.

A turbulent flow double-walled pipe combines the advantages of the double-walled design for protection and insulation, along with the enhanced fluid dynamics of turbulent flow, making it suitable for applications that demand effective heat transfer and fluid mixing capabilities.

The principle of turbulent flow double-walled pipe is based on two factors:

- Distribution of gas-solid mixture in horizontal conveying pipes: Due to the influence of gravity, the gas-solid mixture forms a distribution with more gas in the upper part of the pipe and more solid particles in the lower part.

- Occurrence of blockage phenomenon: In horizontal conveying pipes, when a blockage occurs, the solid particles will first accumulate on the lower wall of the pipe and gradually build up towards the upper wall, eventually completely blocking the pipe.

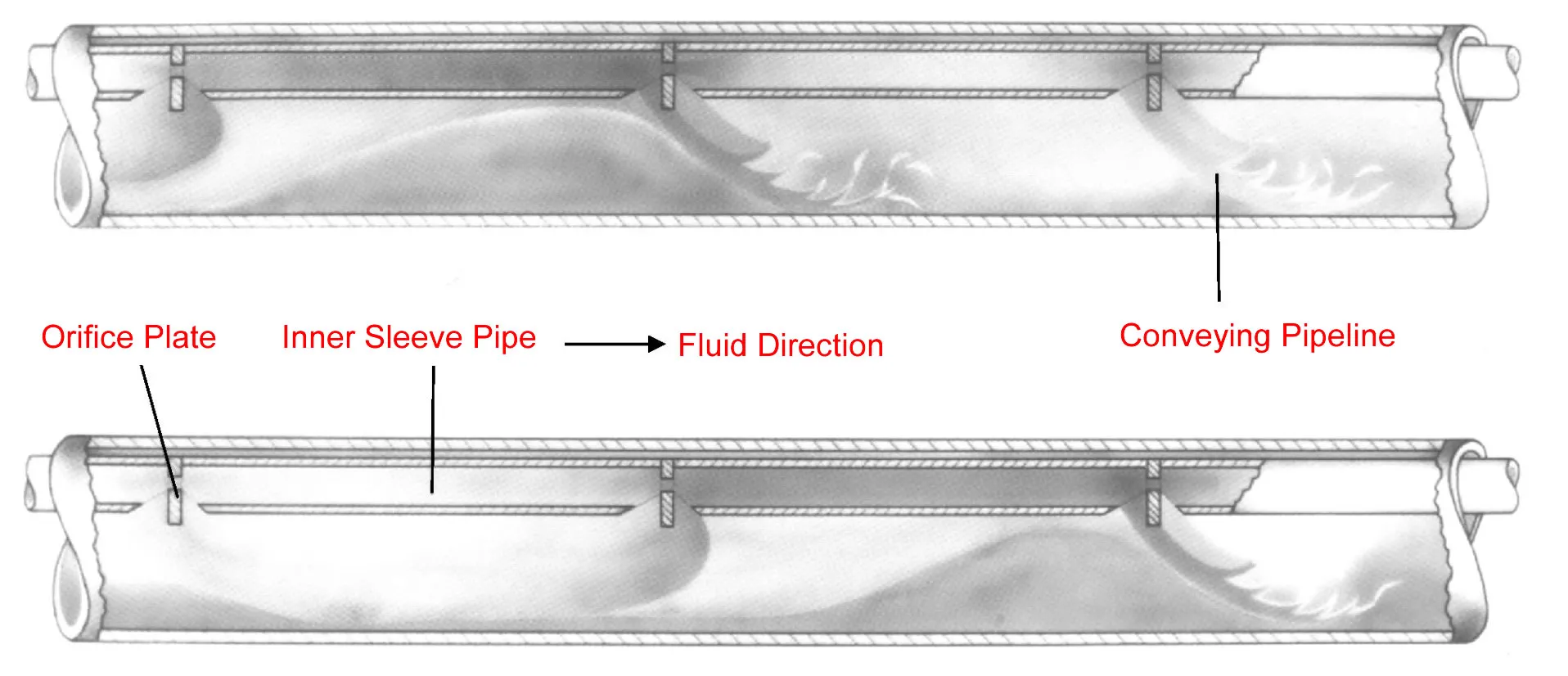

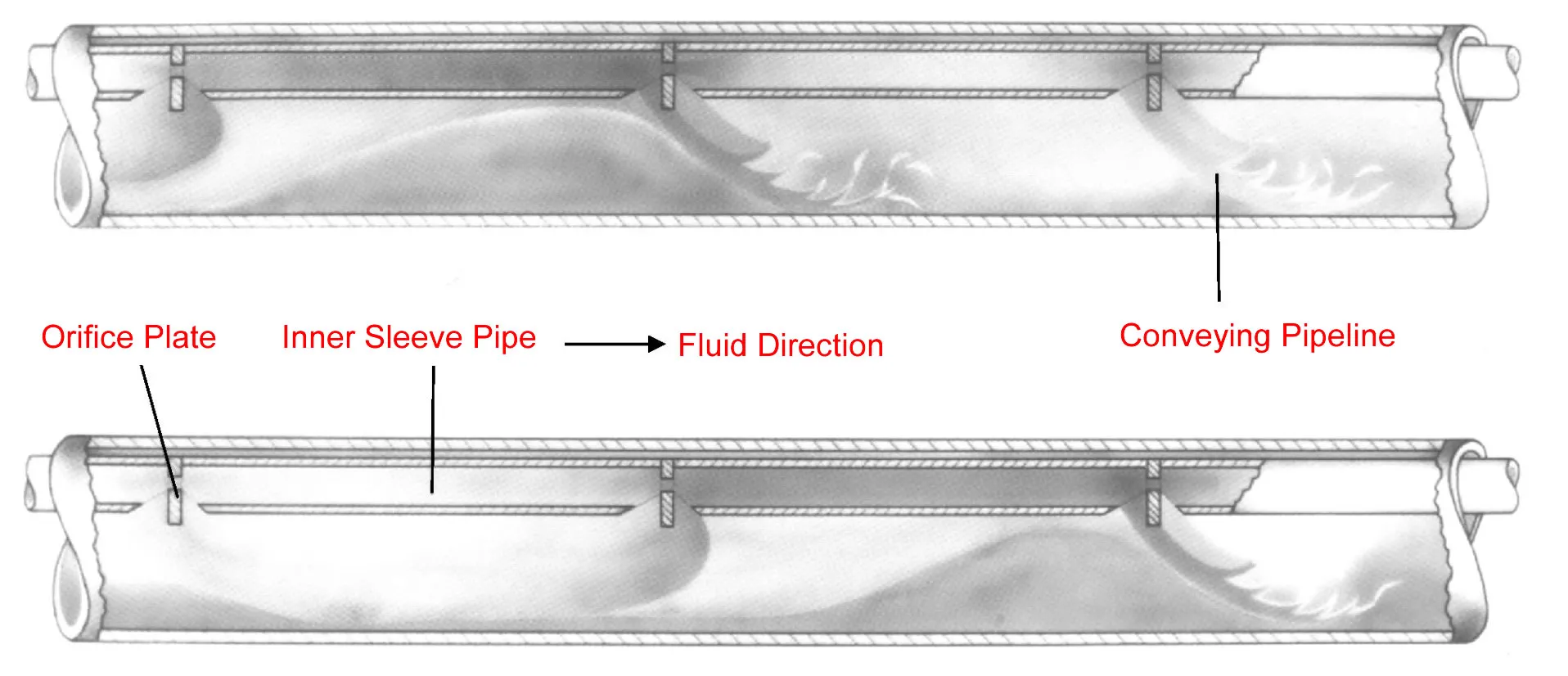

By applying turbulent flow double-walled pipes to the horizontal pneumatic conveying pipes, it effectively prevents pipe blockage, and the anti-blocking mechanism lies in the special structure of the double-walled pipe. When the ash-gas mixture flows inside the pipe, it often causes gradual deposition of dry ash within the pipe, leading to blockage. When blockage starts to occur, compressed air flows through the small pipe, and through the openings and throttle orifices on the small pipe, the blocked section is disturbed, gradually dislodging the deposited dry ash, thereby avoiding complete blockage of the conveying pipe.

Structure and Working Principle of Double-walled Pipe

Working Principle: An auxiliary air pipe is added above the conveying pipe, with nozzles installed at regular intervals along the auxiliary air pipe. The air and material mixture enters the double-walled pipe at a low velocity under the conveying pressure and moves slowly forward inside the pipe. When material deposition and blockage occur due to low flow velocity, air flows through the auxiliary air pipe and exits at high velocity through the nozzles, disturbing and clearing the deposited material, allowing it to continue moving forward. This continuous disturbance ensures dense-phase, low-speed material transportation without blockages, ensuring safe and reliable system operation. As the system may experience instantaneous blockages, it incorporates some plug flow conveying, which determines the characteristics of low-speed, high solid-to-gas ratio transportation. Due to its ability to automatically detect blockage locations, adjust the air velocity inside the small pipe according to blockage conditions, and perform automatic clearing, it possesses the unique technical advantage of never blocking.

Main Technical Features of Double-walled Pipe

- Special structure and conveying principle, ensuring a blockage-free system.

- Low conveying speed, resulting in minimal equipment and pipeline wear.

- Low positive-pressure dense-phase plug flow conveying, providing high conveying efficiency.

- High system output and low energy consumption during operation.

- Safe and reliable system operation, suitable for long-distance conveying, and can be started or stopped at any time without blockages.

- Modular operation, simple configuration, and cost-effective equipment investment.

- Fully automated program control can be achieved.

- Strong adaptability, suitable for conveying materials with large particle size and high specific gravity.

Economic Indicators of Double-walled Pipe Technology

- High conveying density, with 30% higher solid-to-gas ratio than other conveying systems.

- Low conveying velocity, with a starting velocity of 2-5m/s.

- Light pipe wear, with the service life of ordinary carbon steel conveying pipes reaching up to 10 years.

- Low energy consumption, with energy consumption per ton-kilometer not exceeding 4kWh/t.km.

- High conveying output, providing 30% more output under the same conditions compared to other systems.

- Long conveying distance, reaching over 2000 meters.