Special wear-resistant alloys

Special wear-resistant alloys are designed to withstand various types of wear (such as abrasive, adhesive, erosive, or impact wear) in harsh environments.

Special wear-resistant alloys are designed to withstand various types of wear (such as abrasive, adhesive, erosive, or impact wear) in harsh environments.

Engineered for high-performance abrasion, impact, and corrosion resistance in industrial environments.

| Alloy Type | Key Composition | Typical Hardness | Applications |

|---|---|---|---|

| Ni-Hard 4 (ASTM A532) | Cr 9%, Ni 5.5% | ≥ 600 HB | Slurry pipes, elbows, mills |

| High Chromium White Cast Iron | Cr 16–28% | HRC 55–65 | Coal mills, ash transport |

| Chromium Carbide Overlay (CCO) | Fe + Cr carbide overlay | HRC 60–63 | Wear liners, chutes |

| Mn Steel (Hadfield) | Mn 11–14% | ~ 220 HB (work hardening) | Jaw plates, hammers |

| Inconel / Hastelloy | Ni, Cr, Mo alloyed | High-temp + corrosion resistance | Boiler shields, acid plants |

Slurry Transport

Power Generation

Cement Industry

Chemical Handling

Cast basalt pipe adopt magma centrifugal casting m...

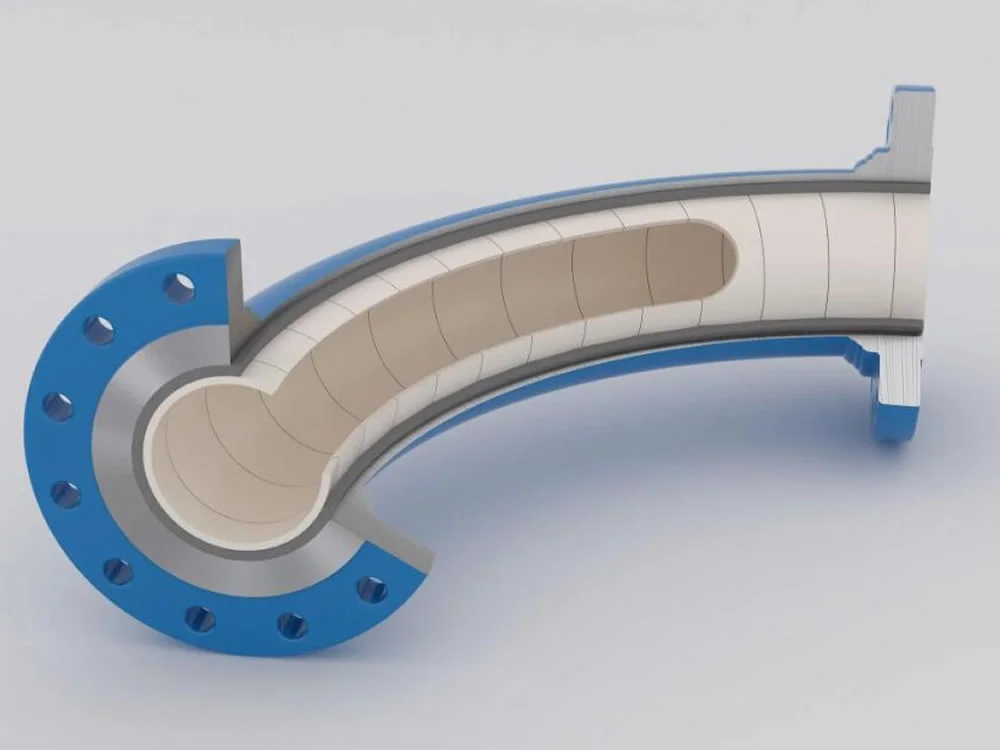

Ceramic-lined pipes combine steel strength with ha...

Silicon carbide ceramic-lined pipes offer ultra-hi...

Ceramic tile lined pipes provide exceptional wear ...

Boiler tubes erosion shields protect against wear ...

Ceramic sleeve lined pipes offer exceptional wear ...