Nickel Based Alloys

Stainless Steel Materials And Processing

Super stainless steels such as duplex steel, super austenitic steel, tantalum-titanium-zirconium, nickel-based alloys, and other high-performance alloys are available in our current stock.

Stainless Steel Materials And Processing

Super stainless steels such as duplex steel, super austenitic steel, tantalum-titanium-zirconium, nickel-based alloys, and other high-performance alloys are available in our current stock.

With long standing relationships with many of the largest producers and stocking distributors across the globe, we specialise in non-standard items and hard to find alloys and product forms.

High-temperature alloys are used by manufacturers of equipment that is subjected to extremely high temperatures, such as jet engines for the aerospace market, gas turbine engines used for power generation and waste incineration, and industrial heating equipment.

Corrosion-resistant alloys are used in applications that require resistance to very corrosive media found in applications, such as chemical processing, power plant emissions control, hazardous waste treatment, sour gas production and pharmaceutical vessels.

Nickel based alloys are engineered to provide outstanding performance under high-temperature, corrosive, or high-stress industrial conditions.

We provide manufacturing and custom fabrication services for:

Nickel alloys combine high nickel content with elements like chromium, molybdenum, and iron to provide enhanced strength at elevated temperatures and superior corrosion resistance.

Though more expensive than carbon steel, nickel-based materials offer unmatched durability and long-term cost-effectiveness, especially in extreme conditions such as chemical processing, marine engineering, and energy systems.

Excellent resistance to acids, seawater, and aggressive industrial environments.

Maintains structural integrity under extreme thermal stress.

Stable under oxidative and high-temperature conditions.

Minimizes deformation under temperature fluctuation.

Nickel and its alloys are used across thousands of industrial applications. Below is a selection of typical components and systems.

A common solid-liquid separation device used in environmental protection processes such as flue gas treatment and wastewater control.

Critical to the chemical industry for separating mixtures into desired components during chemical reactions and processing.

Used in electrolytic cells and electrochemical systems, providing current conduction at the positive pole in water treatment.

Applied in desulfurization and denitrification towers to protect inner walls from corrosion, chemical attack, and mechanical abrasion.

Converts liquids into vapor for chemical concentration, separation, and purification in process industries.

Used in marine pipeline systems for fluid drainage, ventilation, and outlet piping in ship hulls and decks.

Custom-fabricated pipe assemblies for shipbuilding and modular installations, improving construction efficiency and quality.

Installed in piping systems to absorb thermal expansion and vibration, ensuring long-term structural integrity.

“I can rely on them to take the trouble to help us out which means that I can then deliver to my customers the solutions that they are looking for. Specialty Metals enable us to do our job.”

- Delivery Solutions

Discover how low temperature carbon steel pipes (a...

Astm a335 chrome moly pipes offer superior strengt...

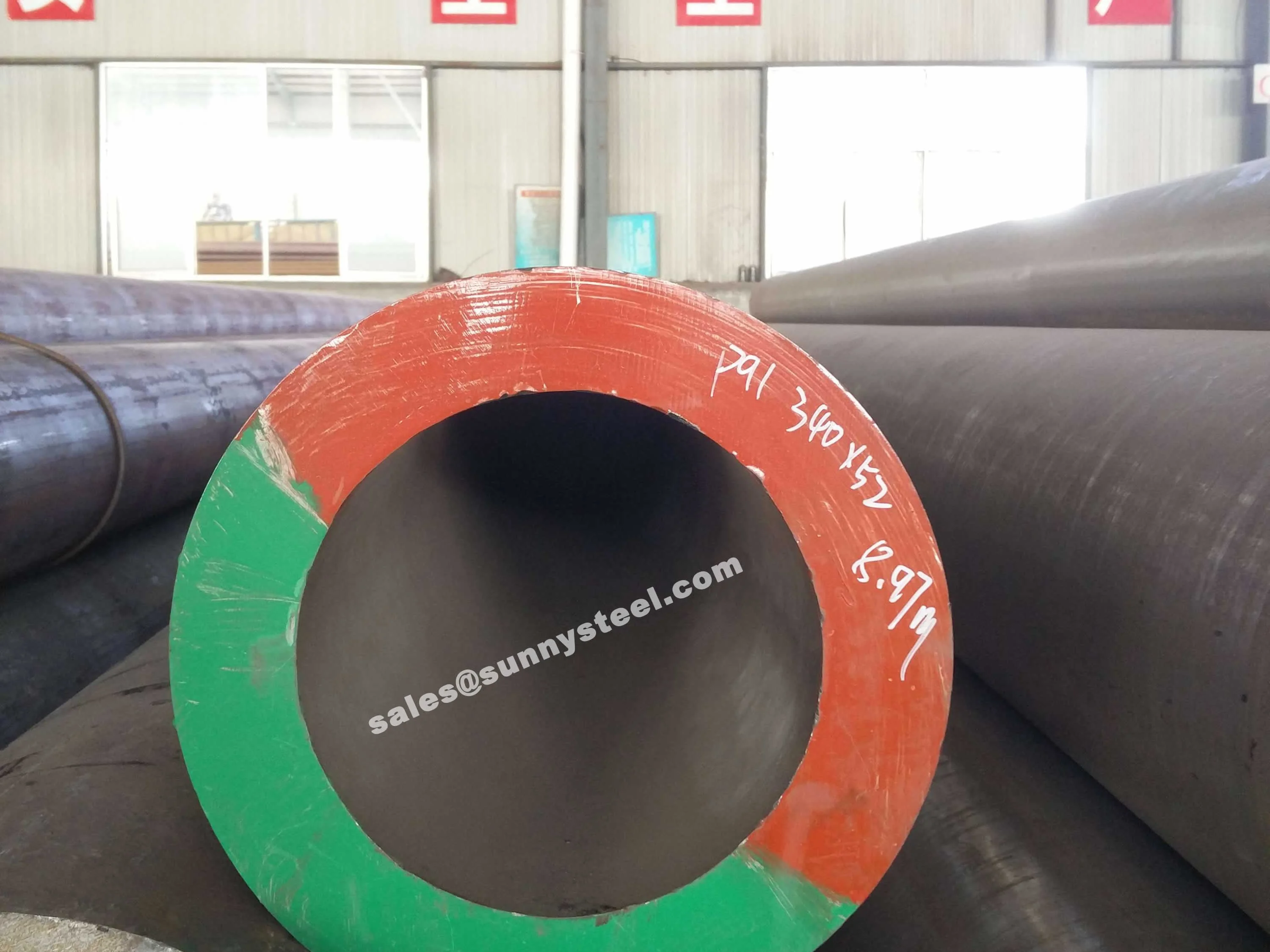

We maintain a large stock of alloy steel pipes wit...

Non-alloy steel tubes offer excellent durability a...

Astm a213 alloy tubes, including grades like t5, t...