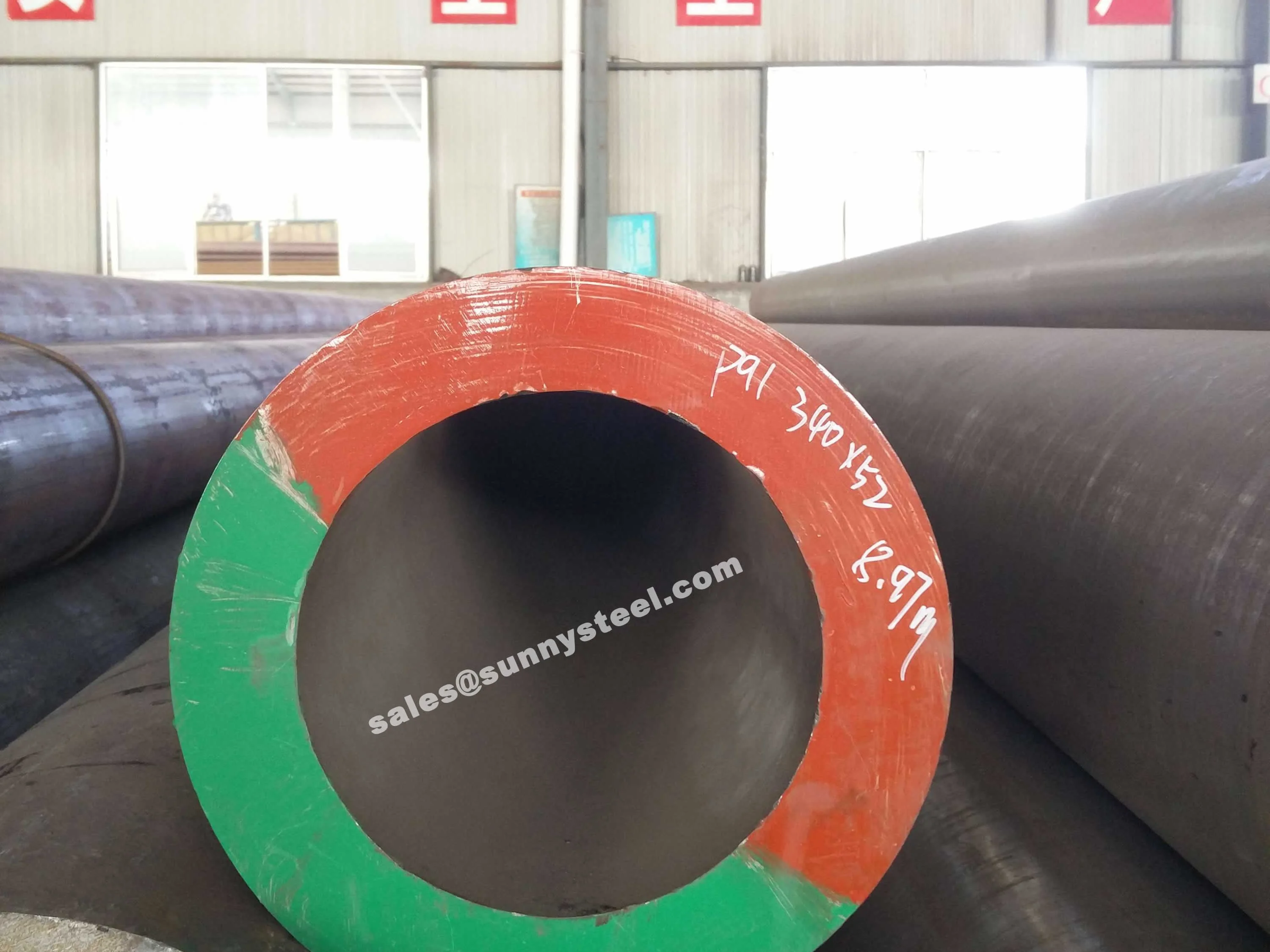

ASTM A335 Chrome Moly Pipe

Your Ultimate Guide To High-temperature Piping Solutions

Astm a335 chrome moly pipes offer superior strength, heat resistance, and pressure performance—ideal for boilers, superheaters, and heat exchangers.

Your Ultimate Guide To High-temperature Piping Solutions

Astm a335 chrome moly pipes offer superior strength, heat resistance, and pressure performance—ideal for boilers, superheaters, and heat exchangers.

ASTM A335 is commonly used for power generation, refineries, and petrochemical industries, especially in high-temperature service applications. Below are the equivalents of ASTM A335 in other standards:

ASTM A335/ASME SA335 is a specification that covers seamless ferritic alloy steel pipe for high-temperature service. It includes various grades of chrome moly alloy pipes, such as P1, P5, P9, P11, P12, P22, P91, and others.

ASTM A335 is a seamless ferritic alloy-steel pipe designed for high-temperature service, offering outstanding performance in thermal and pressure systems.

Withstands temperatures up to 650°C, making it suitable for boilers, superheaters, and pressure vessels.

Resists oxidation and corrosive media commonly found in harsh industrial and high-temperature environments.

Delivers stable performance under thermal stress and high pressure, ideal for demanding applications.

ASTM A335 Chrome Moly Pipe is widely used in power generation, refineries, and petrochemical plants where long-term reliability and resistance to elevated temperatures are critical. Grades such as P11, P22, and P91 offer different balances of strength and heat resistance for specific needs.

ASTM Specification pipe confirming to ASTM A335 shall have the following chemical properties. Tensile and Hardness Requirements The tensile properties of the ASTM A335 pipe shall conform to the requirements as prescribed. Pipe of Grades P91, P92, and P122 shall have a hardness not exceeding 250 HB/265 HV [25 HRC]. For pipe of Grades P91, P92, P122, and P911, Brinell, Vickers, or Rockwell hardness tests shall be made on a specimen from each lot (see Note 7). These pipe bear high resistance to rupture at high temperature and pressures. With hydrogen crack resistance and sulfide stress corrosion cracking chrome moly pipe are highly preferred over Carbon pipe.

| Grade | C | Mn | P max | S max | Si | Cr | Mo | V | N | Others |

|---|---|---|---|---|---|---|---|---|---|---|

| P1 | 0.1-0.2 | 0.3-0.8 | 0.025 | 0.025 | 0.1-0.5 | 1.0-1.5 | 0.44-0.65 | / | / | / |

| P2 | 0.1-0.2 | 0.3-0.61 | 0.025 | 0.025 | 0.1-0.3 | 0.5-0.81 | 0.44-0.65 | / | / | / |

| P5 | ≤0.15 | 0.3-0.6 | 0.025 | 0.025 | ≤0.5 | 4.0-6.0 | 0.45-0.65 | / | / | / |

| P5b | ≤0.15 | 0.3-0.6 | 0.025 | 0.025 | 1.0-2.0 | 4.0-6.0 | 0.45-0.65 | / | / | / |

| P5c | ≤0.12 | 0.3-0.6 | 0.025 | 0.025 | ≤0.5 | 4.0-6.0 | 0.45-0.65 | / | / | / |

| P9 | ≤0.15 | 0.3-0.6 | 0.025 | 0.025 | 0.25-1.0 | 8.0-10.0 | 0.9-1.1 | / | / | / |

| P11 | 0.05-0.15 | 0.3-0.6 | 0.025 | 0.025 | 0.5-1.0 | 1.0-1.5 | 0.44-0.65 | / | / | / |

| P12 | 0.05-0.15 | 0.3-0.61 | 0.025 | 0.025 | ≤0.5 | 0.8-1.25 | 0.44-0.65 | / | / | / |

| P15 | 0.05-0.15 | 0.3-0.6 | 0.025 | 0.025 | 1.15-1.65 | / | 0.44-0.65 | / | / | / |

| P21 | 0.05-0.15 | 0.3-0.6 | 0.025 | 0.025 | ≤0.5 | 2.65-3.35 | 0.8-1.06 | / | / | / |

| P22 | 0.05-0.15 | 0.3-0.6 | 0.025 | 0.025 | ≤0.5 | 1.9-2.6 | 0.87-1.13 | / | / | / |

| P23 | 0.04-0.1 | 0.1-0.6 | 0.03 | 0.01 | ≤0.5 | 1.9-2.6 | 0.05-0.3 | 0.2-0.3 | ≤0.015 | Cb(0.02-0.08), B(0.001-0.006) |

| Al(≤0.03), W(1.45-1.75) | ||||||||||

| Ni(≤0.4), Ti(0.005-0.060) | ||||||||||

| P24 | 0.05-0.1 | 0.3-0.7 | 0.02 | 0.01 | 0.15-0.45 | 2.2-2.6 | 0.9-1.1 | 0.2-0.3 | ≤0.012 | Ti(0.06-0.1), Al(≤0.02) |

| B(0.0015-0.007) | ||||||||||

| P36 | 0.1-0.17 | 0.8-1.2 | 0.03 | 0.025 | 0.25-0.50 | ≤0.30 | 0.25-0.50 | ≤0.02 | ≤0.02 | Ni(1.0-1.3), Cu(0.5-0.8) |

| Cb(0.015-0.045), Al(≤0.050) | ||||||||||

| P91 | 0.08-0.12 | 0.3-0.6 | 0.02 | 0.01 | 0.2-0.5 | 8.0-9.5 | 0.85-1.05 | 0.18-0.25 | 0.03-0.07 | Ni(≤0.4), Al(≤0.02), Cb(0.06-0.1) |

| Ti(≤0.01), Zr(≤0.01) | ||||||||||

| P92 | 0.07-0.13 | 0.3-0.6 | 0.02 | 0.01 | ≤0.50 | 8.5-9.5 | 0.3-0.6 | 0.15-0.25 | 0.03-0.07 | Ni(≤0.4), AL(≤0.02), Cb(0.04-0.09) |

| W(1.5-2.0), B(0.001-0.006) | ||||||||||

| Ti(≤0.01), Zr(≤0.01) | ||||||||||

| P122 | 0.07-0.14 | ≤0.7 | 0.02 | 0.01 | ≤0.50 | 10.0-11.5 | 0.25-0.6 | 0.15-0.3 | 0.04-0.1 | Ni(≤0.5), Al(≤0.02), Ti(≤0.01) |

| W(1.5-2.5), Cu(0.3-1.7), Zr(≤0.01) | ||||||||||

| Cb(0.04-0.1), B(0.0005-0.005) | ||||||||||

| P911 | 0.09-0.13 | 0.3-0.6 | 0.02 | 0.01 | 0.1-0.5 | 8.5-9.5 | 0.9-1.1 | 0.18-0.25 | 0.04-0.09 | Ni(≤0.4), Cb(0.06-0.1) |

| B(0.0003-0.006), Al(≤0.02) | ||||||||||

| W(0.9-1.1), Ti(≤0.01), Zr(≤0.01) |

| Werkstoff / DIN | EN | ASTM |

|---|---|---|

| 1.5415 | 16Mo3 | A335 Grade P1 |

| 1.7335 | 13CrMo4-5 | A335 Grade P11, P12 |

| 1.738 | 10CrMo9-10 | A335 Grade P22 |

| 1.7362 | X11CrMo5 | A335 Grade P5 |

| A335 Grade P9 | ||

| 1.4903 | X10CrMoVNb9-1 | A335 Grade P91 |

| Property | P-5 | P-9 | P-11 | P-22 | P-91 |

|---|---|---|---|---|---|

| Tensile Strength, min. | Minimum tensile strength values | ||||

| ksi | 60 | 60 | 60 | 60 | 85 |

| MPa | 415 | 415 | 415 | 415 | 585 |

| Yield Strength, min. | Minimum yield strength values | ||||

| ksi | 30 | 30 | 30 | 30 | 60 |

| MPa | 205 | 205 | 205 | 205 | 415 |

Product Analysis At the request of the purchaser, an analysis of two pipe from each lot shall be made by the manufacturer. A lot of ASTM A335 pipe shall consist of the following: NPS Designator Under 2 400 or fraction thereof 2 to 5 200 or fraction thereof 6 and over 100 or fraction thereof. Note: ASTM A335 P91 shall not have a hardness not exceeding 250 HB/265 HV [25HRC].

| Grade | Heat Treatment Type | Normalizing Temperature Range F [C] | Subcritical Annealing or Tempering Temperature Range F [C] |

|---|---|---|---|

| A335 P5 (b,c) | Full or Isothermal Anneal | - | - |

| Normalize and Temper | ***** | 1250 [675] | |

| Subcritical Anneal (P5c only) | ***** | 1325 – 1375 [715 - 745] | |

| A335 P9 | Full or Isothermal Anneal | - | - |

| Normalize and Temper | ***** | 1250 [675] | |

| A335 P11 | Full or Isothermal Anneal | - | - |

| Normalize and Temper | ***** | 1200 [650] | |

| A335 P22 | Full or Isothermal Anneal | - | - |

| Normalize and Temper | ***** | 1250 [675] | |

| A335 P91 | Normalize and Temper | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

| Quench and Temper | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

ASTM A335 chrome moly pipes are widely used in various industries due to their excellent mechanical properties and resistance to high temperatures.

Used in high-temperature and high-pressure boiler tubes, superheaters, and reheaters for efficient energy conversion.

Applied in refineries and petrochemical plants to transport high-temperature hydrocarbons.

Used in facilities handling corrosive and high-temperature fluids during various chemical reactions.

Employed in nuclear power plants for critical piping systems resistant to extreme heat and pressure.

Used in furnaces and heat exchangers due to excellent resistance to high temperature and thermal fatigue.

Applied in high-pressure steam systems in industries like pulp and paper where thermal durability is essential.

Discover how low temperature carbon steel pipes (a...

We maintain a large stock of alloy steel pipes wit...

Non-alloy steel tubes offer excellent durability a...

Astm a213 alloy tubes, including grades like t5, t...

Super stainless steels such as duplex steel, super...