High-temperature Alloy Steel Pipe For Industrial Use

Astm a335 p5 alloy steel pipe provides excellent high-temperature strength and corrosion resistance, ideal for boiler and industrial pipeline protection in demanding environments.

High-temperature Alloy Steel Pipe For Industrial Use

Astm a335 p5 alloy steel pipe provides excellent high-temperature strength and corrosion resistance, ideal for boiler and industrial pipeline protection in demanding environments.

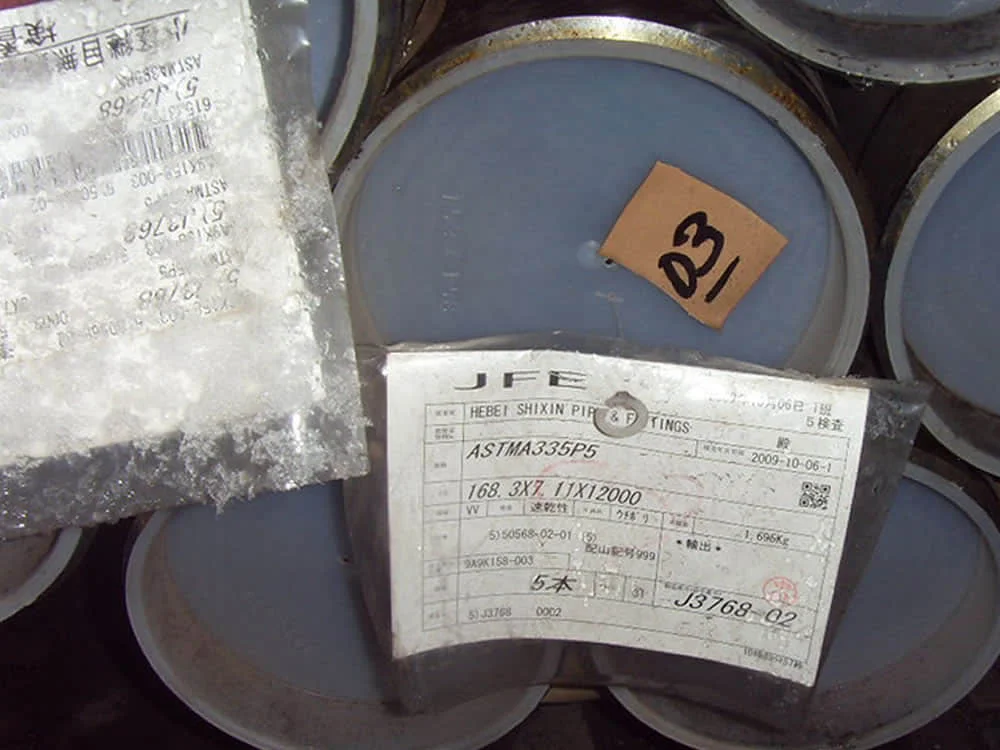

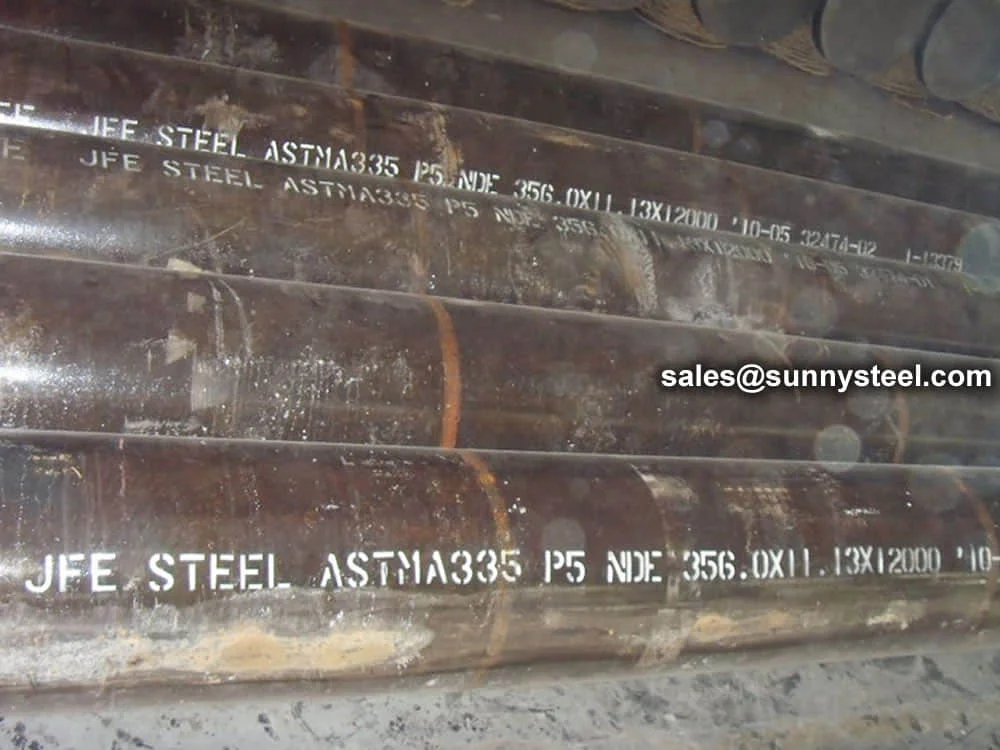

ASTM A335 P5 Alloy Steel Pipe is a seamless ferritic alloy steel pipe engineered for high-temperature applications, providing excellent corrosion resistance and heat resistance. Manufactured to meet ASTM A335/ASME SA335 specifications, this Chrome Moly Pipe features a chemical composition optimized for durability and stability under extreme operating conditions. It is widely used in power plants, refineries, and petrochemical industries for boiler tube protection and other high-pressure pipeline systems.

The pipe is produced through hot-rolling and heat treatment processes to achieve superior mechanical properties, including enhanced tensile strength, yield strength, and creep resistance at temperatures up to 550°C. Its seamless construction ensures uniformity and reliability, minimizing the risk of weld failures or structural weaknesses. The alloy’s balanced chromium and molybdenum content improves oxidation resistance and reduces susceptibility to corrosion and wear in aggressive industrial environments.

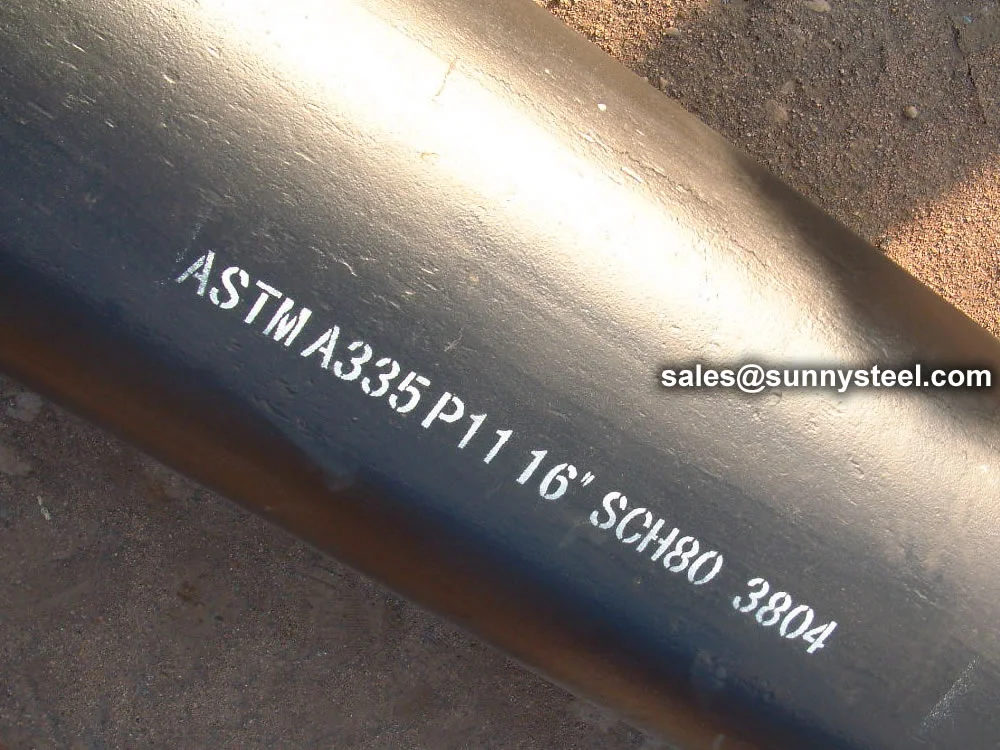

ASTM A335 P5 Alloy Steel Pipe supports various fabrication techniques, including bending, welding, and flanging, with recommended preheat and post-weld heat treatment to maintain metallurgical integrity. Available in a range of sizes and thicknesses, it suits diverse project requirements from boiler tubing to high-temperature process piping.

The pipe undergoes stringent quality control measures, including tensile testing, hardness checks, and hydrostatic pressure testing, to ensure compliance with ASTM standards. Its ability to resist thermal stress, oxidation, and corrosive chemicals makes it ideal for harsh applications in energy generation and chemical processing industries.

Compared to other alloy steel pipes like P11 or P22, the P5 grade offers a balanced solution for moderate temperature ranges where corrosion resistance and mechanical strength are crucial. It is a cost-effective choice for protecting critical industrial pipelines and equipment subject to heat and corrosive media.

Engineers and project managers rely on ASTM A335 P5 Alloy Steel Pipe for its proven performance in boiler pipeline protection and industrial wear resistance, ensuring long service life and reduced maintenance costs in challenging environments.

Reliable performance at temperatures up to 550°C for boiler and industrial piping.

Balanced chromium and molybdenum content protects against oxidation and chemical attack.

Seamless construction reduces abrasion and mechanical wear in demanding applications.

Uniform metallurgical properties ensure stability under high pressure and thermal stress.

Long service life reduces downtime and replacement expenses.

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.05-0.12 |

| Manganese (Mn) | 0.30-0.60 |

| Phosphorus (P) | ≤0.025 |

| Sulfur (S) | ≤0.025 |

| Silicon (Si) | 0.10-0.40 |

| Chromium (Cr) | 1.75-2.50 |

| Molybdenum (Mo) | 0.45-0.65 |

| Property | Value |

|---|---|

| Tensile Strength, min (MPa) | 415 |

| Yield Strength, min (MPa) | 205 |

| Elongation, min (%) | 25 (Longitudinal) |

| Hardness, max (HB) | 200 |

ASTM A335 chrome moly pipes are widely used in various industries due to their excellent mechanical properties and resistance to high temperatures.

Used in high-temperature and high-pressure boiler tubes, superheaters, and reheaters for efficient energy conversion.

Applied in refineries and petrochemical plants to transport high-temperature hydrocarbons.

Used in facilities handling corrosive and high-temperature fluids during various chemical reactions.

Employed in nuclear power plants for critical piping systems resistant to extreme heat and pressure.

Used in furnaces and heat exchangers due to excellent resistance to high temperature and thermal fatigue.

Applied in high-pressure steam systems in industries like pulp and paper where thermal durability is essential.

Astm a335 p11 alloy steel pipe provides reliable h...

Astm a335 p92 high pressure boiler pipe delivers e...

Astm a335 p22 pipe offers excellent corrosion resi...