Seamless Chrome Moly Pipe For High-temperature Use

Astm a335 p11 alloy steel pipe provides reliable high-temperature strength and corrosion resistance, ideal for boiler tubes and industrial piping in demanding environments.

Seamless Chrome Moly Pipe For High-temperature Use

Astm a335 p11 alloy steel pipe provides reliable high-temperature strength and corrosion resistance, ideal for boiler tubes and industrial piping in demanding environments.

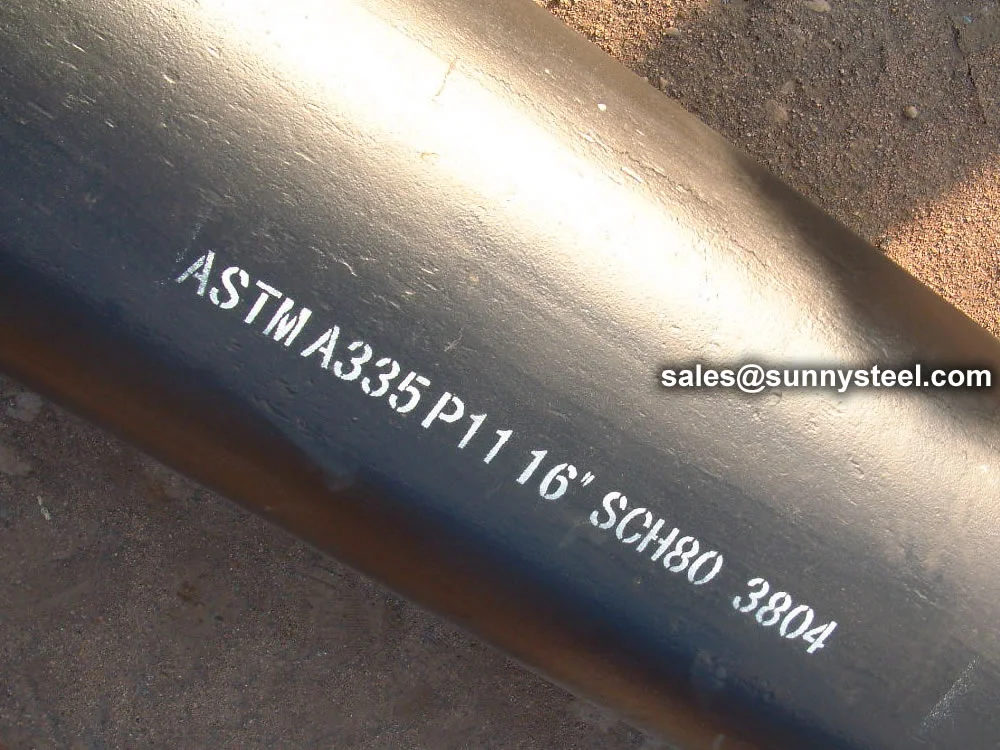

ASTM A335 P11 Alloy Steel Pipe is a seamless ferritic alloy steel pipe primarily used for high-temperature service in power generation, oil refineries, and petrochemical industries. Designed per ASTM A335/ASME SA335 standards, this Chrome Moly Pipe combines excellent heat resistance with superior corrosion resistance, making it ideal for high-pressure piping systems, especially in boiler applications.

The alloy contains 1.00-1.50% chromium and 0.44-0.65% molybdenum, enhancing the material's resistance to oxidation, creep, and chemical attack at elevated temperatures. Its seamless construction ensures structural integrity under thermal stress, with typical operating temperatures up to 550°C. This grade supports fabrication methods including bending, flanging, and welding with appropriate preheating and post-weld heat treatment to ensure metallurgical stability.

ASTM A335 P11 Pipe is available in a wide range of nominal sizes from DN15 to DN600, with various wall thicknesses (SCH 40 to SCH 160) and up to 12 meters in length. Its compatibility with ASTM A234 WP11 fittings ensures system consistency in industrial piping installations.

The pipe undergoes rigorous mechanical and non-destructive testing, including tensile, hardness, and hydrostatic tests. Its balanced mechanical properties provide dependable performance in steam lines, heat exchangers, and pressure vessels handling corrosive or abrasive media.

Compared to grades like P9 or P22, P11 alloy pipe offers a cost-effective solution for medium-temperature applications requiring moderate strength and corrosion protection. Its dependable performance and weldability make it a preferred material in thermal power stations and petrochemical systems.

ASTM A335 P11 is engineered to solve critical issues such as pipe deformation, thermal fatigue, and corrosion in challenging high-temperature pipelines. Its chemical stability and heat resistance deliver long-term efficiency with reduced maintenance costs.

Operates efficiently in temperatures up to 550°C in power and chemical systems.

Chrome and moly enhance resistance against chemical and steam corrosion.

Seamless pipe withstands pressure cycling and thermal expansion fatigue.

Uniform composition ensures stable performance in welded and flanged joints.

Cost-effective choice for medium-temperature industrial applications.

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.05–0.15 |

| Manganese (Mn) | 0.30–0.60 |

| Phosphorus (P) | ≤0.025 |

| Sulfur (S) | ≤0.025 |

| Silicon (Si) | 0.50–1.00 |

| Chromium (Cr) | 1.00–1.50 |

| Molybdenum (Mo) | 0.44–0.65 |

| Property | Value |

|---|---|

| Tensile Strength, min (MPa) | 415 |

| Yield Strength, min (MPa) | 205 |

| Elongation, min (%) | 30 (Longitudinal) |

| Hardness, max (HB) | 187 |

ASTM A335 P11 Pipe is fully compatible with ASTM A234 WP11 alloy steel fittings, ensuring a seamless connection for high-temperature and high-pressure piping systems. These fittings include elbows, reducers, tees, caps, and stub ends, fabricated from the same Chrome Moly alloy material.

All WP11 fittings are manufactured through hot forming and subsequent heat treatment to match the mechanical and chemical properties of P11 pipe. This consistency guarantees structural integrity, uniform thermal expansion, and excellent weldability across the entire system.

Change flow direction in high-temperature pipelines.

Branch connections for steam or hot gas distribution lines.

Smooth transitions and secure pipe terminations.

| Grade | Cr (%) | Mo (%) | Max Service Temp (°C) | Typical Applications |

|---|---|---|---|---|

| P11 | 1.00–1.50 | 0.44–0.65 | ~550°C | Boilers, Superheaters, Heat Exchangers |

| P22 | 1.90–2.50 | 0.85–1.05 | ~600°C | Steam Lines, Refinery Units |

| P5 | 4.00–6.00 | 0.45–0.65 | ~580°C | Hydrogen Reactors, Furnace Tubes |

| P9 | 8.00–10.00 | 0.90–1.10 | ~620°C | Reheat Lines, High-temp Furnaces |

ASTM A335 is a seamless ferritic alloy-steel pipe designed for high-temperature service, offering outstanding performance in thermal and pressure systems.

Withstands temperatures up to 650°C, making it suitable for boilers, superheaters, and pressure vessels.

Resists oxidation and corrosive media commonly found in harsh industrial and high-temperature environments.

Delivers stable performance under thermal stress and high pressure, ideal for demanding applications.

ASTM A335 Chrome Moly Pipe is widely used in power generation, refineries, and petrochemical plants where long-term reliability and resistance to elevated temperatures are critical. Grades such as P11, P22, and P91 offer different balances of strength and heat resistance for specific needs.

ASTM Specification pipe confirming to ASTM A335 shall have the following chemical properties. Tensile and Hardness Requirements The tensile properties of the ASTM A335 pipe shall conform to the requirements as prescribed. Pipe of Grades P91, P92, and P122 shall have a hardness not exceeding 250 HB/265 HV [25 HRC]. For pipe of Grades P91, P92, P122, and P911, Brinell, Vickers, or Rockwell hardness tests shall be made on a specimen from each lot (see Note 7). These pipe bear high resistance to rupture at high temperature and pressures. With hydrogen crack resistance and sulfide stress corrosion cracking chrome moly pipe are highly preferred over Carbon pipe.

| Grade | C | Mn | P max | S max | Si | Cr | Mo | V | N | Others |

|---|---|---|---|---|---|---|---|---|---|---|

| P1 | 0.1-0.2 | 0.3-0.8 | 0.025 | 0.025 | 0.1-0.5 | 1.0-1.5 | 0.44-0.65 | / | / | / |

| P2 | 0.1-0.2 | 0.3-0.61 | 0.025 | 0.025 | 0.1-0.3 | 0.5-0.81 | 0.44-0.65 | / | / | / |

| P5 | ≤0.15 | 0.3-0.6 | 0.025 | 0.025 | ≤0.5 | 4.0-6.0 | 0.45-0.65 | / | / | / |

| P5b | ≤0.15 | 0.3-0.6 | 0.025 | 0.025 | 1.0-2.0 | 4.0-6.0 | 0.45-0.65 | / | / | / |

| P5c | ≤0.12 | 0.3-0.6 | 0.025 | 0.025 | ≤0.5 | 4.0-6.0 | 0.45-0.65 | / | / | / |

| P9 | ≤0.15 | 0.3-0.6 | 0.025 | 0.025 | 0.25-1.0 | 8.0-10.0 | 0.9-1.1 | / | / | / |

| P11 | 0.05-0.15 | 0.3-0.6 | 0.025 | 0.025 | 0.5-1.0 | 1.0-1.5 | 0.44-0.65 | / | / | / |

| P12 | 0.05-0.15 | 0.3-0.61 | 0.025 | 0.025 | ≤0.5 | 0.8-1.25 | 0.44-0.65 | / | / | / |

| P15 | 0.05-0.15 | 0.3-0.6 | 0.025 | 0.025 | 1.15-1.65 | / | 0.44-0.65 | / | / | / |

| P21 | 0.05-0.15 | 0.3-0.6 | 0.025 | 0.025 | ≤0.5 | 2.65-3.35 | 0.8-1.06 | / | / | / |

| P22 | 0.05-0.15 | 0.3-0.6 | 0.025 | 0.025 | ≤0.5 | 1.9-2.6 | 0.87-1.13 | / | / | / |

| P23 | 0.04-0.1 | 0.1-0.6 | 0.03 | 0.01 | ≤0.5 | 1.9-2.6 | 0.05-0.3 | 0.2-0.3 | ≤0.015 | Cb(0.02-0.08), B(0.001-0.006) |

| Al(≤0.03), W(1.45-1.75) | ||||||||||

| Ni(≤0.4), Ti(0.005-0.060) | ||||||||||

| P24 | 0.05-0.1 | 0.3-0.7 | 0.02 | 0.01 | 0.15-0.45 | 2.2-2.6 | 0.9-1.1 | 0.2-0.3 | ≤0.012 | Ti(0.06-0.1), Al(≤0.02) |

| B(0.0015-0.007) | ||||||||||

| P36 | 0.1-0.17 | 0.8-1.2 | 0.03 | 0.025 | 0.25-0.50 | ≤0.30 | 0.25-0.50 | ≤0.02 | ≤0.02 | Ni(1.0-1.3), Cu(0.5-0.8) |

| Cb(0.015-0.045), Al(≤0.050) | ||||||||||

| P91 | 0.08-0.12 | 0.3-0.6 | 0.02 | 0.01 | 0.2-0.5 | 8.0-9.5 | 0.85-1.05 | 0.18-0.25 | 0.03-0.07 | Ni(≤0.4), Al(≤0.02), Cb(0.06-0.1) |

| Ti(≤0.01), Zr(≤0.01) | ||||||||||

| P92 | 0.07-0.13 | 0.3-0.6 | 0.02 | 0.01 | ≤0.50 | 8.5-9.5 | 0.3-0.6 | 0.15-0.25 | 0.03-0.07 | Ni(≤0.4), AL(≤0.02), Cb(0.04-0.09) |

| W(1.5-2.0), B(0.001-0.006) | ||||||||||

| Ti(≤0.01), Zr(≤0.01) | ||||||||||

| P122 | 0.07-0.14 | ≤0.7 | 0.02 | 0.01 | ≤0.50 | 10.0-11.5 | 0.25-0.6 | 0.15-0.3 | 0.04-0.1 | Ni(≤0.5), Al(≤0.02), Ti(≤0.01) |

| W(1.5-2.5), Cu(0.3-1.7), Zr(≤0.01) | ||||||||||

| Cb(0.04-0.1), B(0.0005-0.005) | ||||||||||

| P911 | 0.09-0.13 | 0.3-0.6 | 0.02 | 0.01 | 0.1-0.5 | 8.5-9.5 | 0.9-1.1 | 0.18-0.25 | 0.04-0.09 | Ni(≤0.4), Cb(0.06-0.1) |

| B(0.0003-0.006), Al(≤0.02) | ||||||||||

| W(0.9-1.1), Ti(≤0.01), Zr(≤0.01) |

| Werkstoff / DIN | EN | ASTM |

|---|---|---|

| 1.5415 | 16Mo3 | A335 Grade P1 |

| 1.7335 | 13CrMo4-5 | A335 Grade P11, P12 |

| 1.738 | 10CrMo9-10 | A335 Grade P22 |

| 1.7362 | X11CrMo5 | A335 Grade P5 |

| A335 Grade P9 | ||

| 1.4903 | X10CrMoVNb9-1 | A335 Grade P91 |

| Property | P-5 | P-9 | P-11 | P-22 | P-91 |

|---|---|---|---|---|---|

| Tensile Strength, min. | Minimum tensile strength values | ||||

| ksi | 60 | 60 | 60 | 60 | 85 |

| MPa | 415 | 415 | 415 | 415 | 585 |

| Yield Strength, min. | Minimum yield strength values | ||||

| ksi | 30 | 30 | 30 | 30 | 60 |

| MPa | 205 | 205 | 205 | 205 | 415 |

Product Analysis At the request of the purchaser, an analysis of two pipe from each lot shall be made by the manufacturer. A lot of ASTM A335 pipe shall consist of the following: NPS Designator Under 2 400 or fraction thereof 2 to 5 200 or fraction thereof 6 and over 100 or fraction thereof. Note: ASTM A335 P91 shall not have a hardness not exceeding 250 HB/265 HV [25HRC].

| Grade | Heat Treatment Type | Normalizing Temperature Range F [C] | Subcritical Annealing or Tempering Temperature Range F [C] |

|---|---|---|---|

| A335 P5 (b,c) | Full or Isothermal Anneal | - | - |

| Normalize and Temper | ***** | 1250 [675] | |

| Subcritical Anneal (P5c only) | ***** | 1325 – 1375 [715 - 745] | |

| A335 P9 | Full or Isothermal Anneal | - | - |

| Normalize and Temper | ***** | 1250 [675] | |

| A335 P11 | Full or Isothermal Anneal | - | - |

| Normalize and Temper | ***** | 1200 [650] | |

| A335 P22 | Full or Isothermal Anneal | - | - |

| Normalize and Temper | ***** | 1250 [675] | |

| A335 P91 | Normalize and Temper | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

| Quench and Temper | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

ASTM A335 chrome moly pipes are widely used in various industries due to their excellent mechanical properties and resistance to high temperatures.

Used in high-temperature and high-pressure boiler tubes, superheaters, and reheaters for efficient energy conversion.

Applied in refineries and petrochemical plants to transport high-temperature hydrocarbons.

Used in facilities handling corrosive and high-temperature fluids during various chemical reactions.

Employed in nuclear power plants for critical piping systems resistant to extreme heat and pressure.

Used in furnaces and heat exchangers due to excellent resistance to high temperature and thermal fatigue.

Applied in high-pressure steam systems in industries like pulp and paper where thermal durability is essential.

Astm a335 p5 alloy steel pipe provides excellent h...

Astm a335 p92 high pressure boiler pipe delivers e...

Astm a335 p22 pipe offers excellent corrosion resi...