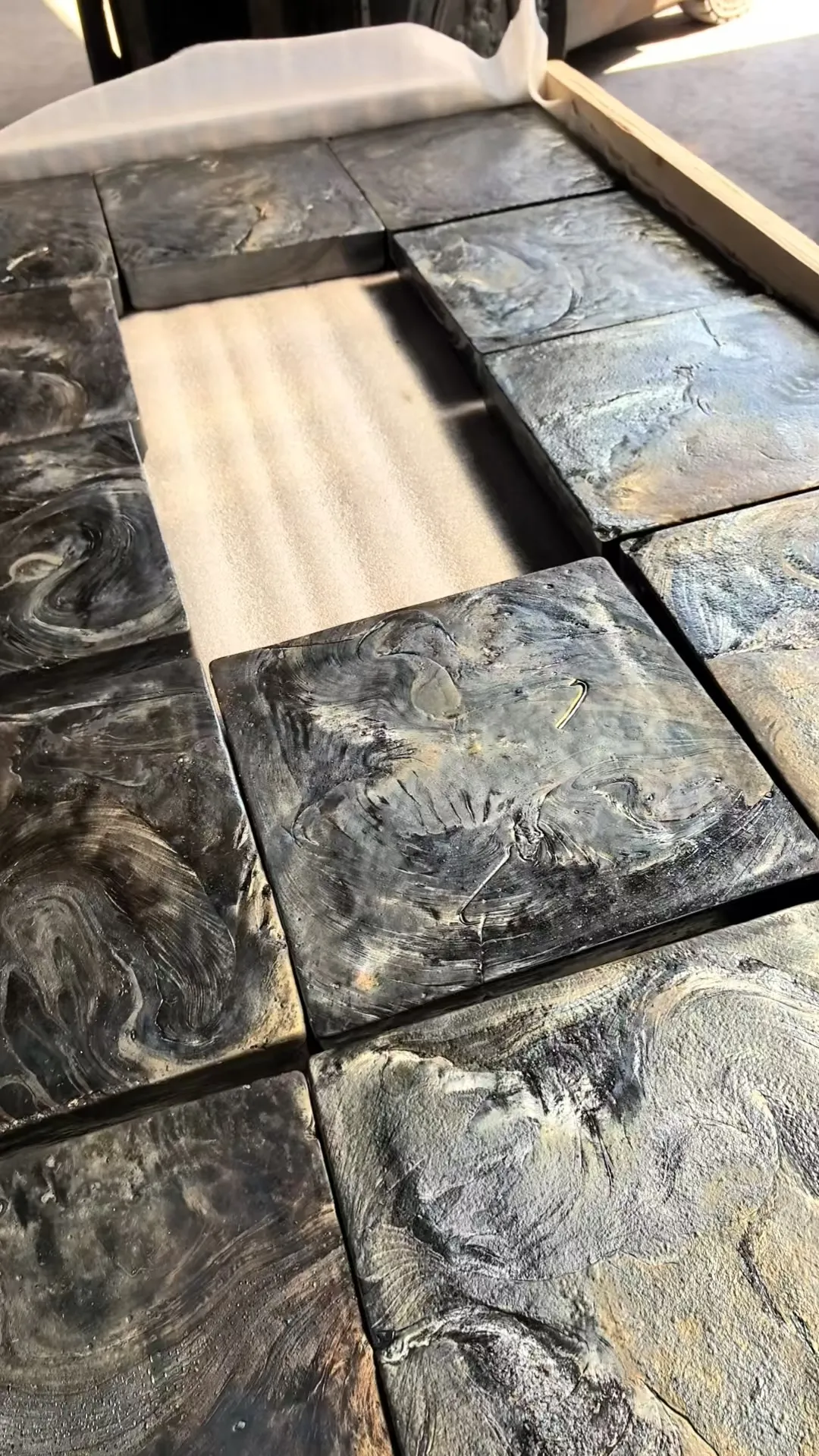

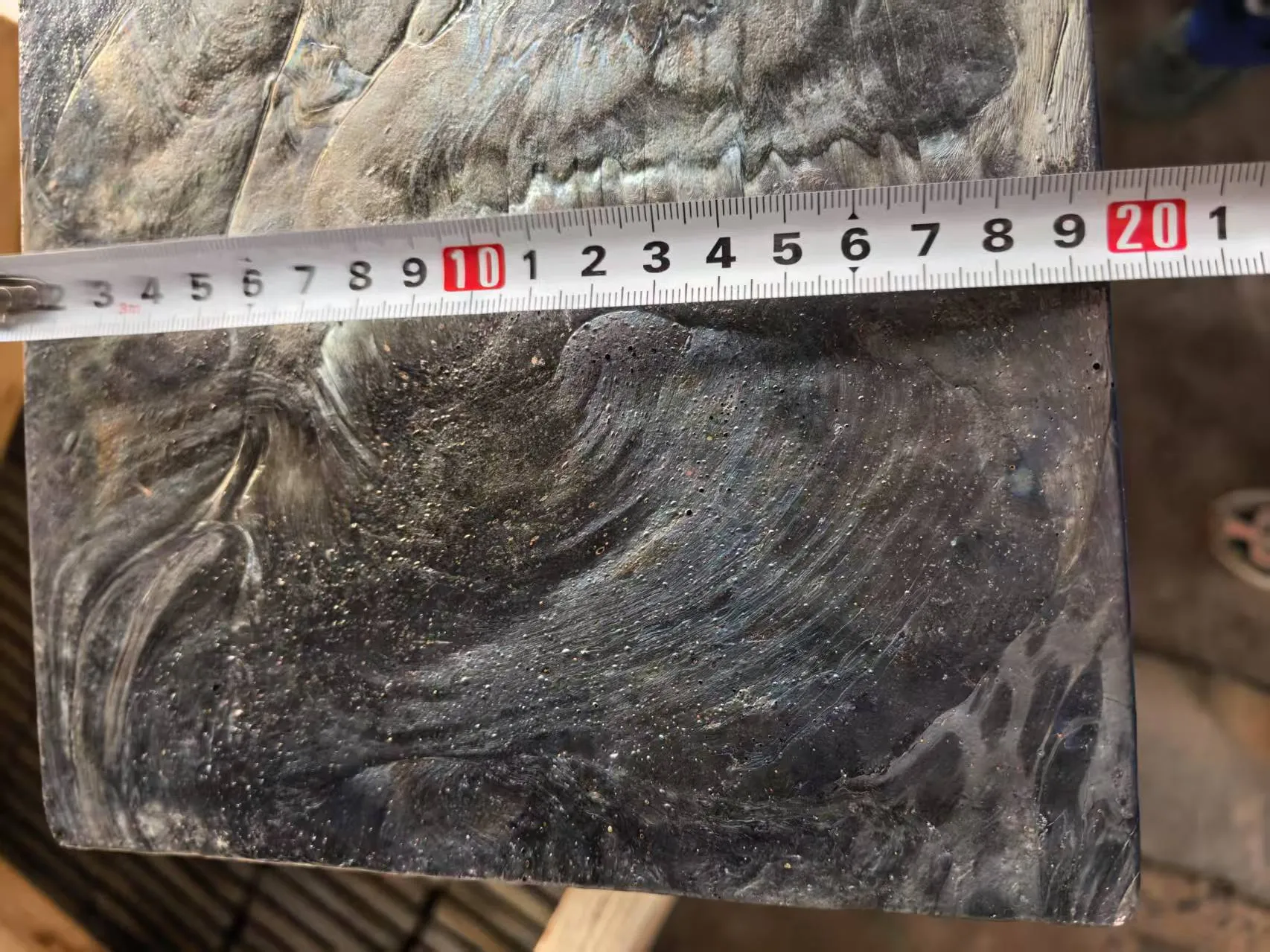

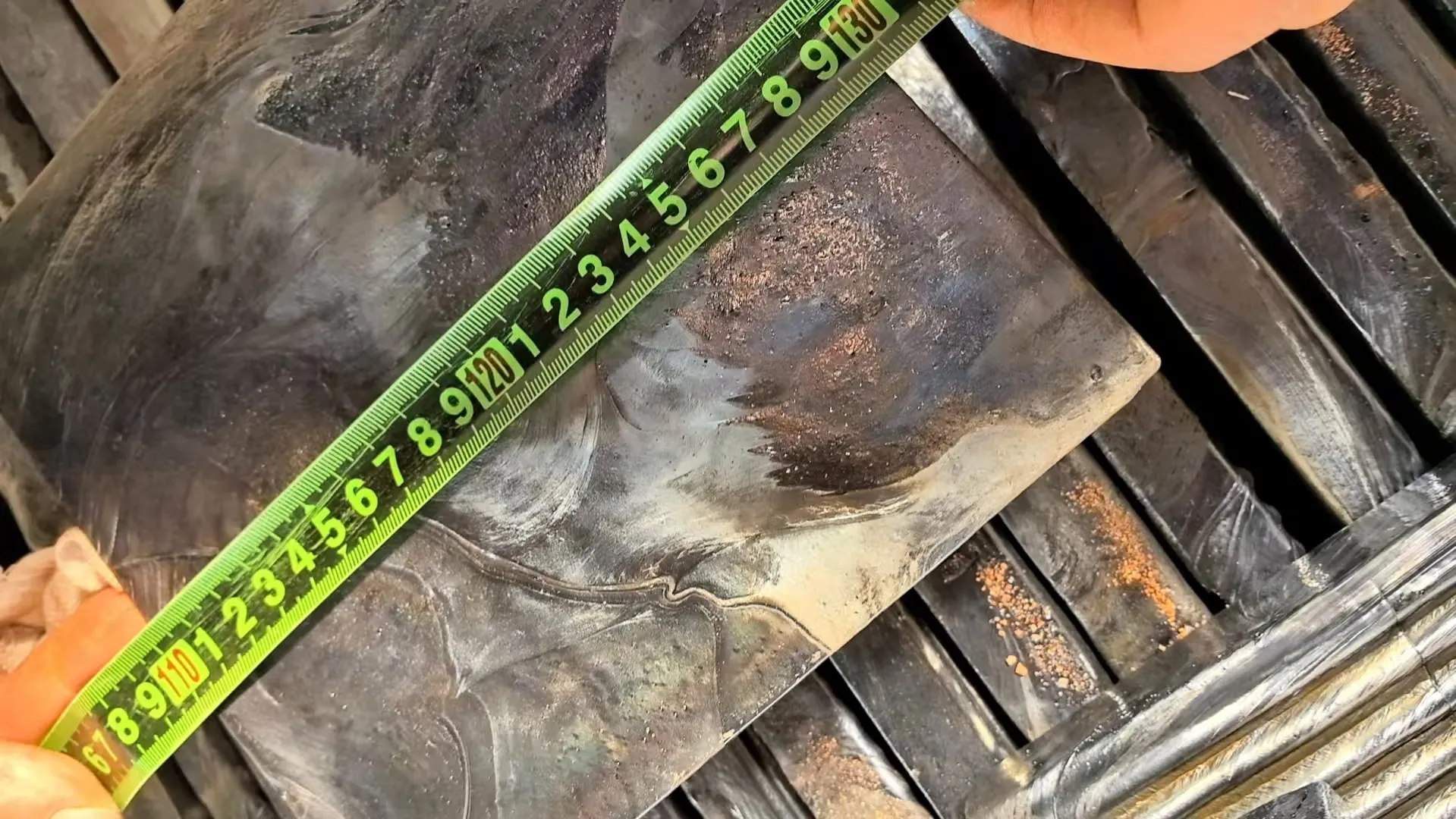

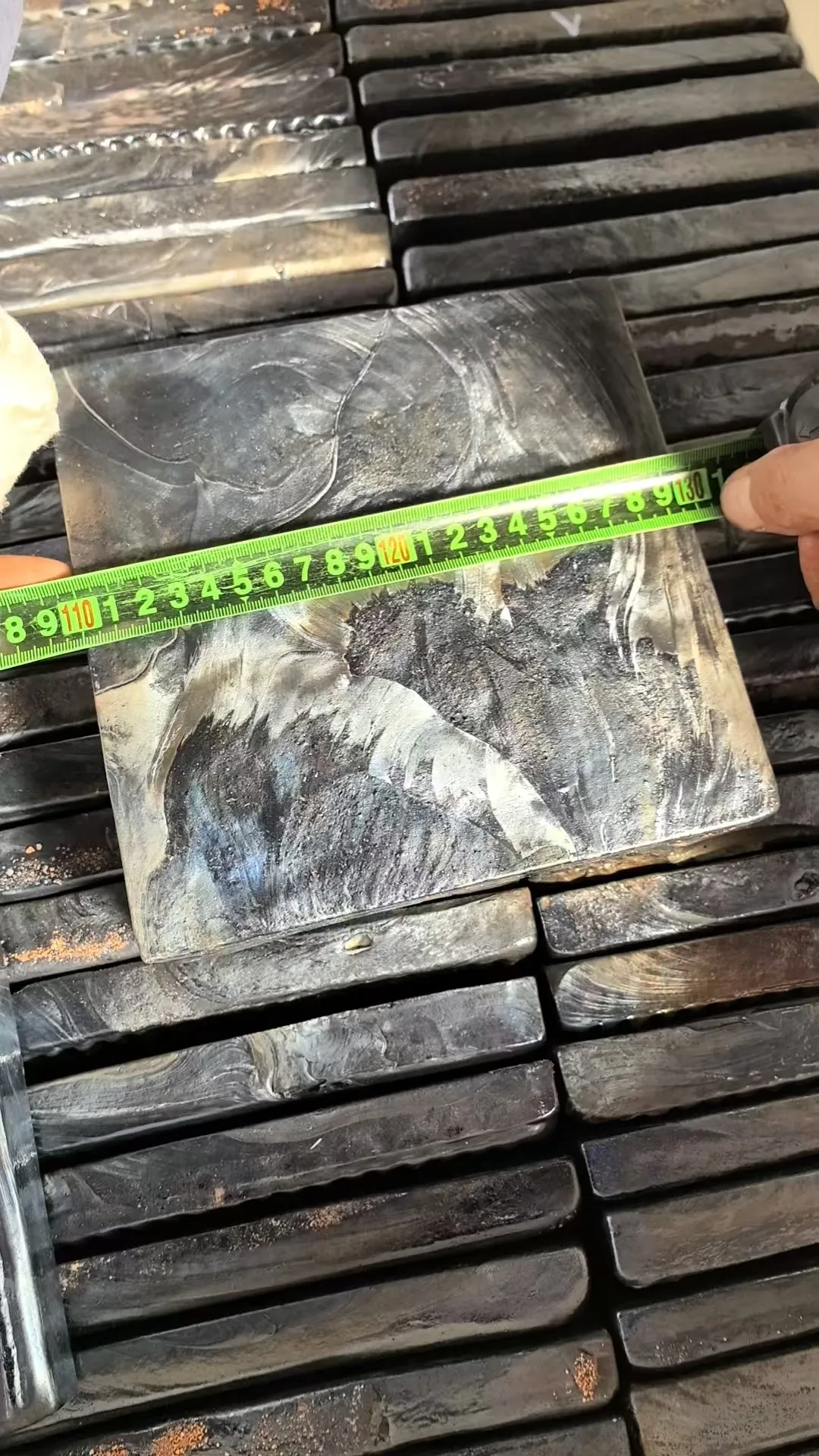

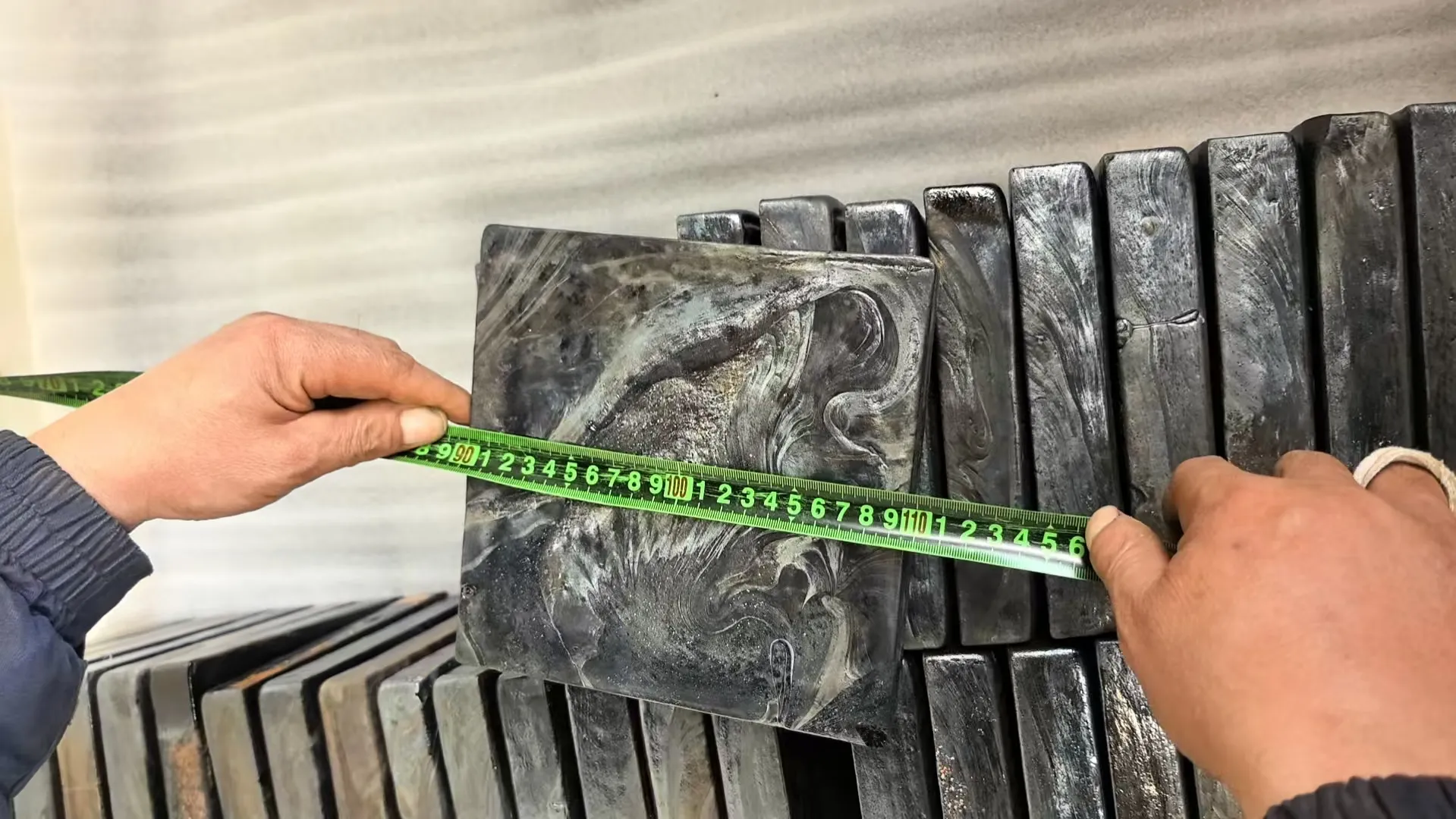

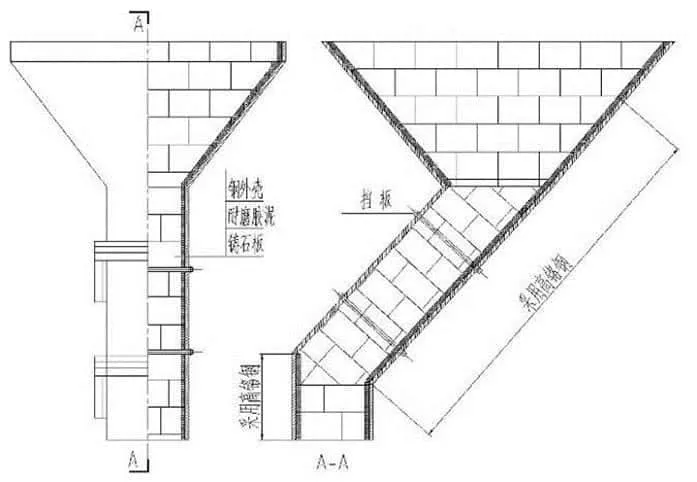

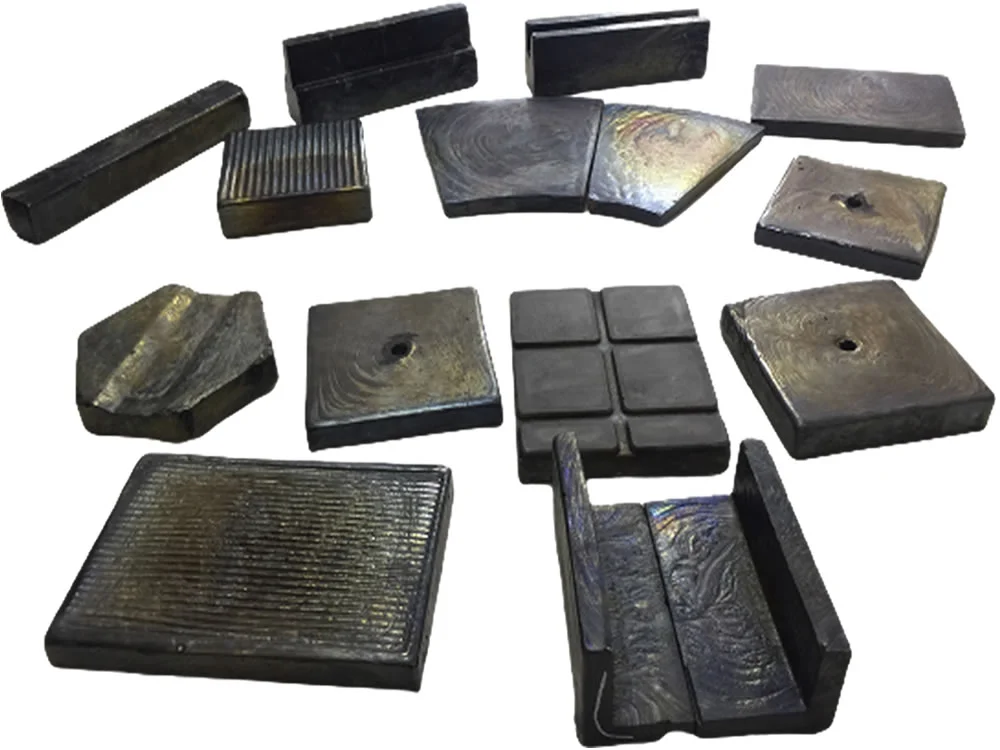

Cast Basalt Tiles

High-Performance Wear-Resistant Basalt Tile Solutions

Cast basalt tiles, abrasion-resistant tiles, wear-resistant lining, corrosion-resistant material, industrial tile lining, basalt lining solutions, durable pipe lining, high-temperature resistant tiles, volcanic rock tiles, heavy-duty industrial tiles.