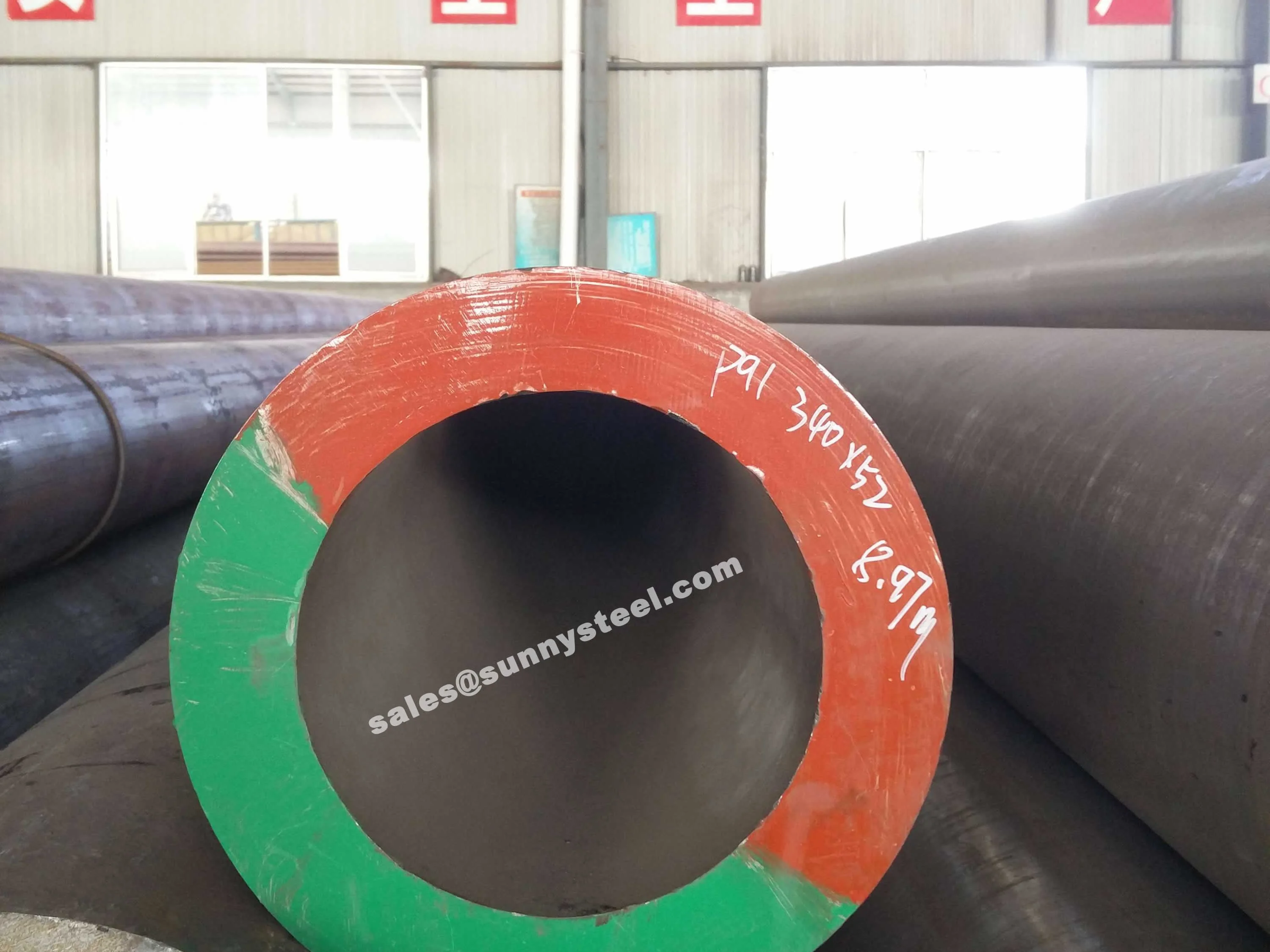

ASTM A213 Alloy Tubes

For Boilers, Superheaters, And Heat Exchangers

Astm a213 alloy tubes, including grades like t5, t9, t11, t22, and t91, offer excellent corrosion and creep resistance, ideal for high-temperature applications in boilers, superheaters, and heat exchangers.