High-temperature Boiler Tubing

Astm a213 t9 seamless alloy tubes offer excellent corrosion resistance and creep strength, ideal for high-temperature applications in boilers, superheaters, and heat exchangers in power plants and petrochemical industries.

High-temperature Boiler Tubing

Astm a213 t9 seamless alloy tubes offer excellent corrosion resistance and creep strength, ideal for high-temperature applications in boilers, superheaters, and heat exchangers in power plants and petrochemical industries.

ASTM A213 T9 Seamless Alloy Steel Pipe is designed for high-temperature service in boilers, superheaters, and heat exchangers. Composed of 8.00–10.00% chromium and 0.90–1.10% molybdenum, this alloy provides excellent strength and corrosion resistance under elevated temperatures.

Manufactured according to ASTM A213 and ASME SA213 standards, T9 pipes undergo rigorous quality control, including tensile, hardness, and hydrostatic testing, ensuring reliability in demanding environments. The seamless construction enhances durability, reducing the risk of failure under thermal stress.

These pipes are suitable for bending, flanging, and welding, with recommended preheating and post-weld heat treatment to maintain structural integrity. Available in various sizes and wall thicknesses, they cater to diverse industrial requirements.

Applications: Power plants, petrochemical industries, and other sectors requiring high-temperature and pressure-resistant piping systems.

| Element | Composition |

|---|---|

| Carbon (C) | ≤ 0.15 |

| Manganese (Mn) | 0.30–0.60 |

| Phosphorus (P) | ≤ 0.025 |

| Sulfur (S) | ≤ 0.025 |

| Silicon (Si) | 0.25–1.00 |

| Chromium (Cr) | 8.00–10.00 |

| Molybdenum (Mo) | 0.90–1.10 |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 415 MPa |

| Yield Strength | ≥ 205 MPa |

| Elongation | ≥ 30% |

| Hardness | ≤ 179 HB |

ASTM A213 is a specification for seamless ferritic and austenitic alloy steel boiler, superheater, and heat-exchanger tubes. These tubes are designed to withstand high temperatures and pressures, making them ideal for use in power generation and petrochemical applications.

Common grades include T91, T92, T11, T12, and T22, each offering unique properties for specific applications. The tubes are manufactured to stringent quality standards, ensuring reliability and performance in demanding environments.

Withstands thermal shock and operates at temperatures up to 650°C for grades like T91 and T92.

Excellent oxidation and corrosion resistance in aggressive chemical and petrochemical environments.

Seamless tubing ensures high structural integrity under pressure and temperature variations.

Improved creep strength and mechanical performance for long-term use in power plants.

Suitable for HRSGs, heat exchangers, boilers, and instrumentation systems in multiple industries.

Supports efficient welding and forming for field installation and system integration.

ASTM A213 T9 Seamless Alloy Steel Pipe are widely used in various industries due to their excellent high-temperature and high-pressure performance.

Utilized in boilers, superheaters, and reheaters within steam power plants due to their high-temperature resistance and durability.

Employed in refineries and chemical plants for transporting high-temperature fluids and gases, ensuring safety and efficiency.

Ideal for use in heat exchangers where thermal stability and corrosion resistance are critical under fluctuating temperatures.

Commonly used in high-pressure boilers and superheaters, offering excellent performance under extreme thermal conditions.

Applied in the extraction and processing of oil and gas, handling high-pressure and high-temperature fluids effectively.

Suitable for equipment in chemical industries where resistance to corrosive substances and high temperatures is essential.

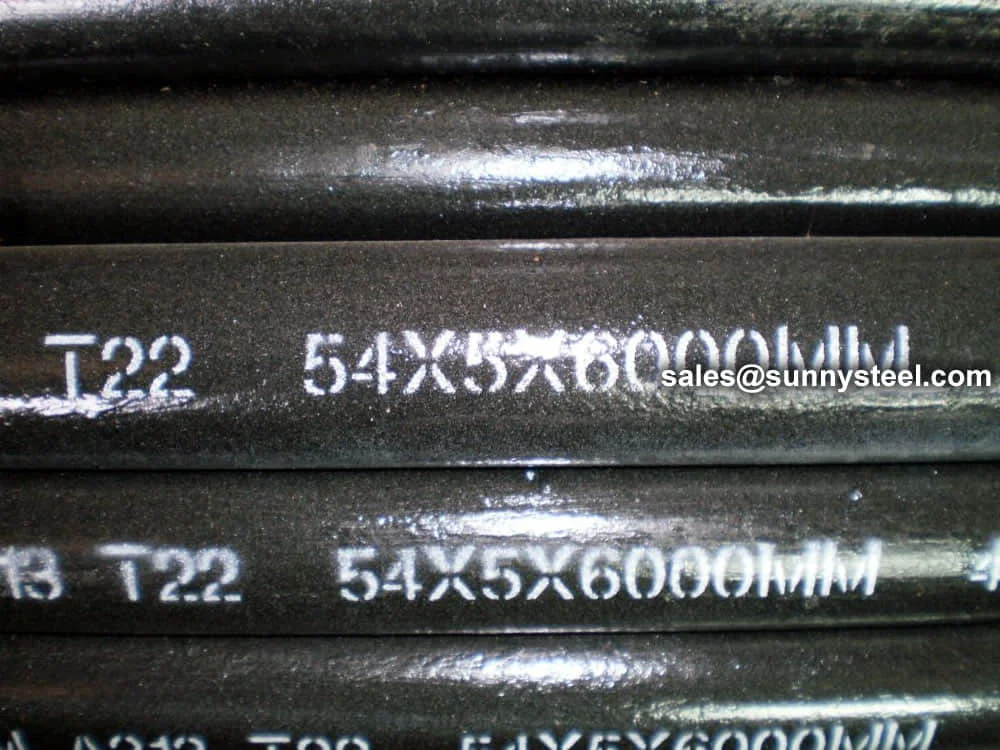

Astm a213 t22 alloy steel pipe offers excellent st...

Astm a213 t91 tubes are seamless alloy steel tubes...

Astm a213 t92 seamless alloy tubes offer superior ...

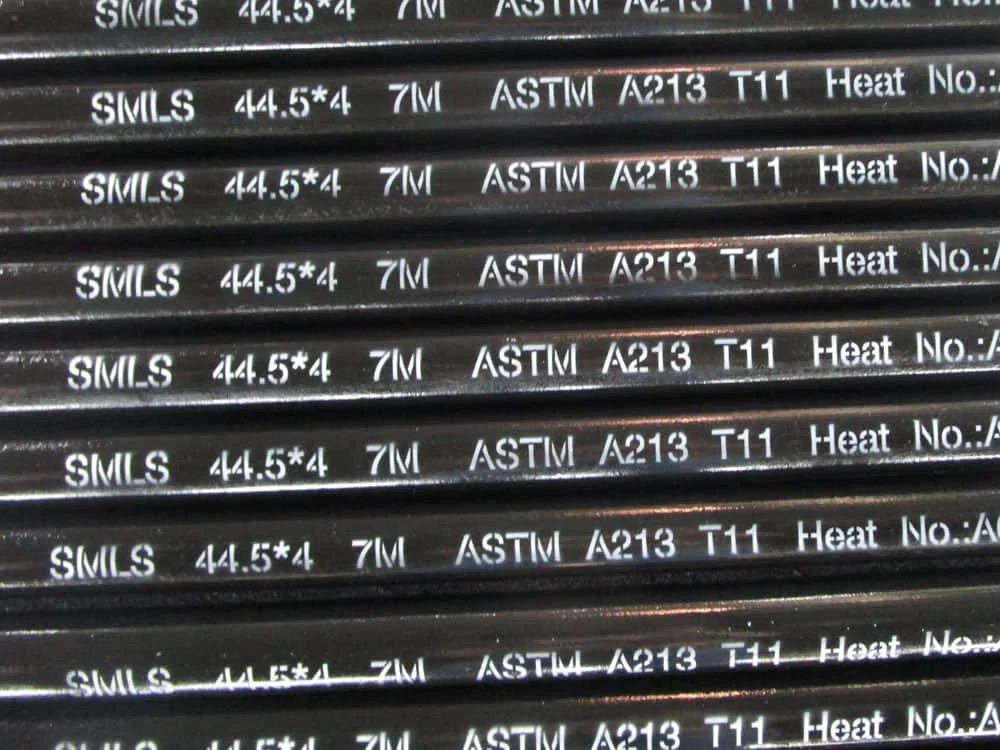

Astm a213 t11 seamless alloy pipe offers excellent...

Astm a213 t24 seamless alloy steel tubes provide s...

Astm a213 t122 seamless alloy pipes offer superior...