High-strength Chrome-moly Tubes For Boilers

Astm a213 t12 seamless alloy pipes offer superior strength and corrosion resistance for high-temperature applications in boilers and heat exchangers.

High-strength Chrome-moly Tubes For Boilers

Astm a213 t12 seamless alloy pipes offer superior strength and corrosion resistance for high-temperature applications in boilers and heat exchangers.

ASTM A213 T12 Seamless Alloy Pipes are high-performance ferritic alloy steel tubes designed for high-temperature service in boilers, superheaters, and heat exchangers. These chrome-moly tubes offer exceptional oxidation resistance and mechanical strength, making them ideal for demanding industrial applications.

Manufactured in accordance with ASTM A213 standards, T12 pipes are typically supplied in annealed, isothermal annealed, or normalized and tempered conditions to achieve optimal mechanical properties. Their seamless construction ensures uniformity and reliability under high-pressure and high-temperature conditions.

The chemical composition includes 0.80–1.25% Chromium and 0.44–0.65% Molybdenum, enhancing their ability to withstand elevated temperatures and corrosive environments. These pipes exhibit a minimum tensile strength of 415 MPa and a minimum yield strength of 220 MPa, ensuring durability and longevity in service.

Common applications encompass high-pressure steam boilers, petrochemical plants, and power generation systems, where resistance to thermal stress and corrosion is critical.

| Element | Composition |

|---|---|

| Carbon (C) | 0.05–0.15 |

| Manganese (Mn) | 0.30–0.61 |

| Phosphorus (P) | ≤ 0.025 |

| Sulfur (S) | ≤ 0.025 |

| Silicon (Si) | ≤ 0.50 |

| Chromium (Cr) | 0.80–1.25 |

| Molybdenum (Mo) | 0.44–0.65 |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 415 MPa |

| Yield Strength | ≥ 220 MPa |

| Elongation | ≥ 30% |

| Hardness | ≤ 163 HB |

| Delivery Condition | Annealed |

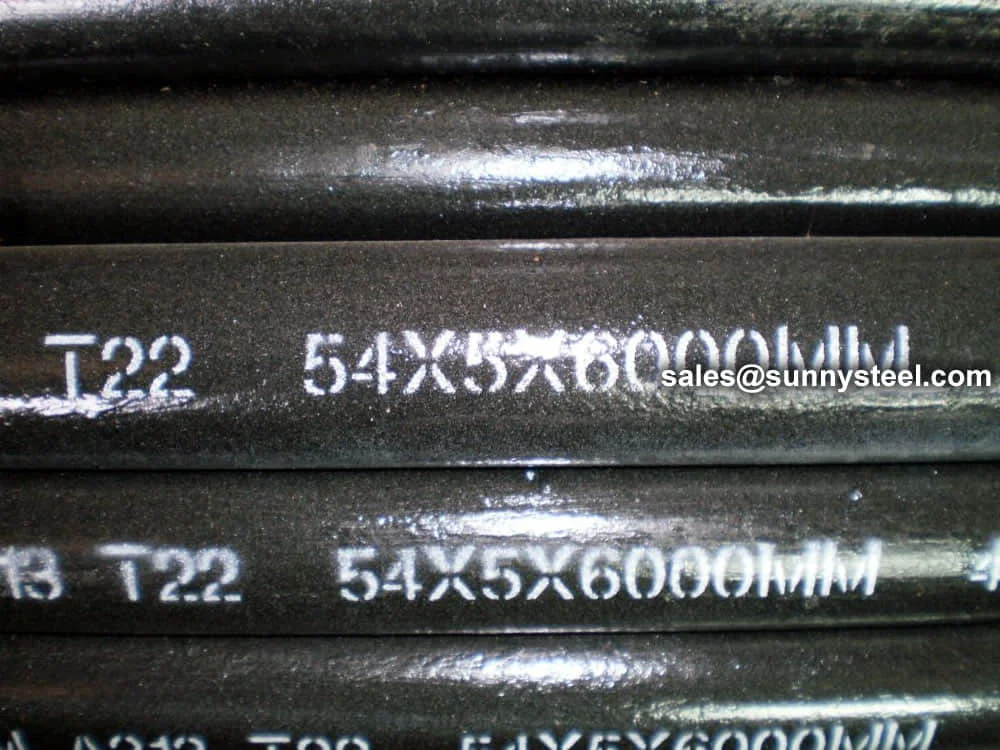

T12 has lower chromium (0.8–1.25% vs. 1.9–2.6%) and molybdenum (0.44–0.65% vs. 0.87–1.13%), resulting in reduced corrosion and creep resistance. T22 handles higher temperatures (up to 593°C vs. 550°C) with similar mechanical strength (415/205 MPa vs. 415/220 MPa).

T9 offers higher chromium content (8–10% vs. 0.8–1.25%), enhancing corrosion resistance and operating temperature (up to 620°C vs. 550°C). Both grades provide similar strength (415/205 MPa vs. 415/220 MPa), but T12 is more cost-effective for less corrosive environments.

T91 incorporates vanadium and niobium, with higher chromium content (8–9.5%) and significantly greater strength (585/415 MPa vs. 415/220 MPa). It is ideal for ultra-supercritical boilers operating up to 650°C, while T12 suits moderate temperature and pressure applications.

T12 (ASTM A213) is used for heat exchanger tubes and boiler tubing (OD 1/8” to 5”) with thinner walls, while P12 (ASTM A335) is used for structural piping (OD 1/8” to 48”) with thicker walls. Both share the same chemical composition (1Cr–0.5Mo) and performance characteristics, but differ in structural application.

ASTM A213 is a specification for seamless ferritic and austenitic alloy steel boiler, superheater, and heat-exchanger tubes. These tubes are designed to withstand high temperatures and pressures, making them ideal for use in power generation and petrochemical applications.

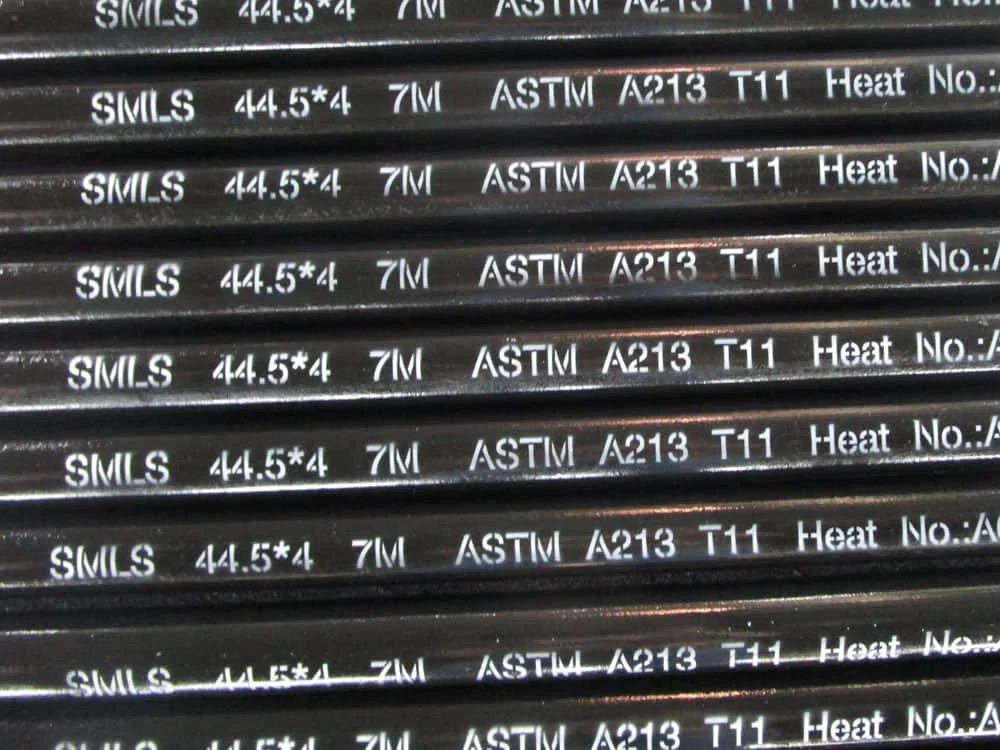

Common grades include T91, T92, T11, T12, and T22, each offering unique properties for specific applications. The tubes are manufactured to stringent quality standards, ensuring reliability and performance in demanding environments.

Withstands thermal shock and operates at temperatures up to 650°C for grades like T91 and T92.

Excellent oxidation and corrosion resistance in aggressive chemical and petrochemical environments.

Seamless tubing ensures high structural integrity under pressure and temperature variations.

Improved creep strength and mechanical performance for long-term use in power plants.

Suitable for HRSGs, heat exchangers, boilers, and instrumentation systems in multiple industries.

Supports efficient welding and forming for field installation and system integration.

Key advantages that make ASTM A213 alloy tubes a preferred choice in high-temperature and corrosive environments.

Maintains structural integrity under extreme heat, ideal for boilers, heat exchangers, and superheaters.

Chromium and molybdenum ensure excellent resistance to oxidation and chemical attack in aggressive media.

Offers high tensile and yield strength, ensuring safe performance under high pressure and temperature.

Durable construction and corrosion resistance extend operational life and minimize maintenance downtime.

Precision manufacturing ensures uniform wall thickness and surface finish, optimizing heat transfer and fit.

Widely used in power generation, petrochemical, and thermal processing industries due to its performance and reliability.

Dimensions and performance data for ASTM A213 tubes and pipes.

| Grade | UNS | C | Mn | P | S | Si | V | B | Nb | N | Al | W |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T2 | K11547 | 0.10–0.20 | 0.30–0.61 | 0.025 | 0.025B | 0.10–0.30 | – | – | – | – | – | – |

| T5 | K41545 | 0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.5 | – | – | – | – | – | – |

| T5b | K51545 | 0.15 | 0.30–0.60 | 0.025 | 0.025 | 1.00–2.00 | – | – | – | – | – | – |

| T5c | K41245 | 0.12 | 0.30–0.60 | 0.025 | 0.025 | 0.5 | – | – | – | – | – | – |

| T9 | K90941 | 0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.25–1.00 | – | – | – | – | – | – |

| T11 | K11597 | 0.05–0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.50–1.00 | – | – | – | – | – | – |

| T12 | K11562 | 0.05–0.15 | 0.30–0.61 | 0.025 | 0.025B | 0.5 | – | – | – | – | – | – |

| T17 | K12047 | 0.15–0.25 | 0.30–0.61 | 0.025 | 0.025 | 0.15–0.35 | 0.15 | – | – | – | – | – |

| T21 | K31545 | 0.05–0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.50–1.00 | – | – | – | – | – | – |

| T22 | K21590 | 0.05–0.15 | 0.30–0.60 | 0.025 | 0.025 | 0.5 | – | – | – | – | – | – |

| T23 | K40712 | 0.04–0.10 | 0.10–0.60 | 0.03 | 0.01 | 0.5 | 0.20–0.30 | 0.0010–0.006 | 0.02–0.08 | 0.015 | 0.03 | 1.45–1.75 |

| T24 | K30736 | 0.05–0.10 | 0.30–0.70 | 0.02 | 0.01 | 0.15–0.45 | 0.20–0.30 | 0.0015–0.007 | – | 0.012 | 0.02 | – |

| T36 | K21001 | 0.10–0.17 | 0.80–1.20 | 0.03 | 0.025 | 0.25–0.50 | 0.02 | – | 0.015–0.045 | 0.02 | 0.05 | – |

| T91 | K90901 | 0.07–0.14 | 0.30–0.60 | 0.02 | 0.01 | 0.20–0.50 | 0.18–0.25 | – | 0.06–0.10 | 0.030–0.07 | 0.02 | – |

| T92 | K92460 | 0.07–0.13 | 0.30–0.60 | 0.02 | 0.01 | 0.5 | 0.15–0.25 | 0.001–0.006 | 0.04–0.09 | 0.030–0.07 | 0.02 | 1.5–2.00 |

| T122 | K91271 | 0.07–0.14 | 0.7 | 0.02 | 0.01 | 0.5 | 0.15–0.30 | 0.0005–0.005 | 0.04–0.10 | 0.040– | 0.02 | 1.50–2.50 |

| T911 | K91061 | 0.09–0.13 | 0.30–0.60 | 0.02 | 0.01 | 0.10–0.50 | 0.18–0.25 | 0.0003–0.006 | 0.06–0.10 | 0.040–0.09 | 0.02 | 0.90–1.10 |

| Grade | Tensile Strength (MPa) |

Yield Point (MPa, min) |

Elongation (%, min) |

Impact (J, min) |

Hardness (HRB, max) |

|---|---|---|---|---|---|

| A213 T2 / SA213 T2 | ≥415 | 205 | – | – | 85 |

| A213 T11 / SA213 T11 | ≥415 | 205 | – | – | 85 |

| A213 T22 / SA213 T22 | ≥415 | 205 | – | – | 85 |

| A213 T23 / SA213 T23 | ≥510 | 400 | 20 | – | 97 |

| A213 T24 / SA213 T24 | ≥585 | 415 | 20 | – | 25 |

| A213 T91 / SA213 T91 | ≥585 | 415 | 20 | – | 25 |

| A213 T911 / SA213 T911 | ≥620 | 440 | 20 | – | 25 |

| A213 T92 / SA213 T92 | ≥620 | 440 | 20 | – | 25 |

| A213 T122 / SA213 T122 | ≥620 | 400 | 20 | – | 25 |

| TP304H | ≥515 | 205 | 35 | – | 90 |

| TP316H | ≥515 | 205 | 35 | – | 90 |

| TP321H | ≥515 | 205 | 35 | – | 90 |

| TP347H | ≥515 | 205 | 35 | – | 90 |

| S30432 | ≥590 | 235 | 35 | – | 95 |

| TP310HCbN | ≥655 | 295 | 30 | – | 100 |

| Grade | UNS Number |

Heat Treat Type | Austenitizing / Solutioning Temp. °F [°C] |

Cooling Media | Annealing / Tempering Temp. °F [°C] |

ASTM Grain Size | |

|---|---|---|---|---|---|---|---|

| T2 | K11547 | Full or Isothermal Anneal | – | – | – | – | |

| Normalize and Temper | – | – | – | – | |||

| Subcritical Anneal | – | – | 1200 to 1350 [650 to 730] |

– | |||

| T5 | K41545 | Full or Isothermal Anneal | – | – | – | – | |

| Normalize and Temper | – | – | 1250 [675] |

– | |||

| T23 | K40712 | Normalize and Temper | 1900–1975 [1040–1080] |

– | 1350–1470 [730–800] |

– | |

| T91 | K90901 | Normalize and Temper | 1900–1975 [1040–1080] |

– | 1350–1470 [730–800] |

– | |

| Parameter | Range | Standard |

|---|---|---|

| Inside Diameter | 1/8" to 5" | 3.2 mm to 127 mm |

| Wall Thickness | 0.015" to 0.500" | 0.4 mm to 12.7 mm |

| Length | 5–7 m / 9–13 m | SRL / DRL |

| Schedule | 40 to 160 | STD, XS, XXS |

| Property | Value | Unit |

|---|---|---|

| Max Service Temperature | 650 | °C |

| Tensile Strength | 415–690 | MPa |

| Yield Strength | 205–520 | MPa |

| Elongation | 20–30 | % |

ASTM A213 T12 Seamless Alloy Pipes are widely used in various industries due to their excellent high-temperature and high-pressure performance.

Utilized in boilers, superheaters, and reheaters within steam power plants due to their high-temperature resistance and durability.

Employed in refineries and chemical plants for transporting high-temperature fluids and gases, ensuring safety and efficiency.

Ideal for use in heat exchangers where thermal stability and corrosion resistance are critical under fluctuating temperatures.

Commonly used in high-pressure boilers and superheaters, offering excellent performance under extreme thermal conditions.

Applied in the extraction and processing of oil and gas, handling high-pressure and high-temperature fluids effectively.

Suitable for equipment in chemical industries where resistance to corrosive substances and high temperatures is essential.

Astm a213 t9 seamless alloy tubes offer excellent ...

Astm a213 t22 alloy steel pipe offers excellent st...

Astm a213 t91 tubes are seamless alloy steel tubes...

Astm a213 t92 seamless alloy tubes offer superior ...

Astm a213 t11 seamless alloy pipe offers excellent...

Astm a213 t24 seamless alloy steel tubes provide s...