Low-temperature Service

Astm a333 grade 6 seamless pipe delivers high impact strength at low temperatures, ideal for cryogenic, lng, and petrochemical pipeline applications.

Low-temperature Service

Astm a333 grade 6 seamless pipe delivers high impact strength at low temperatures, ideal for cryogenic, lng, and petrochemical pipeline applications.

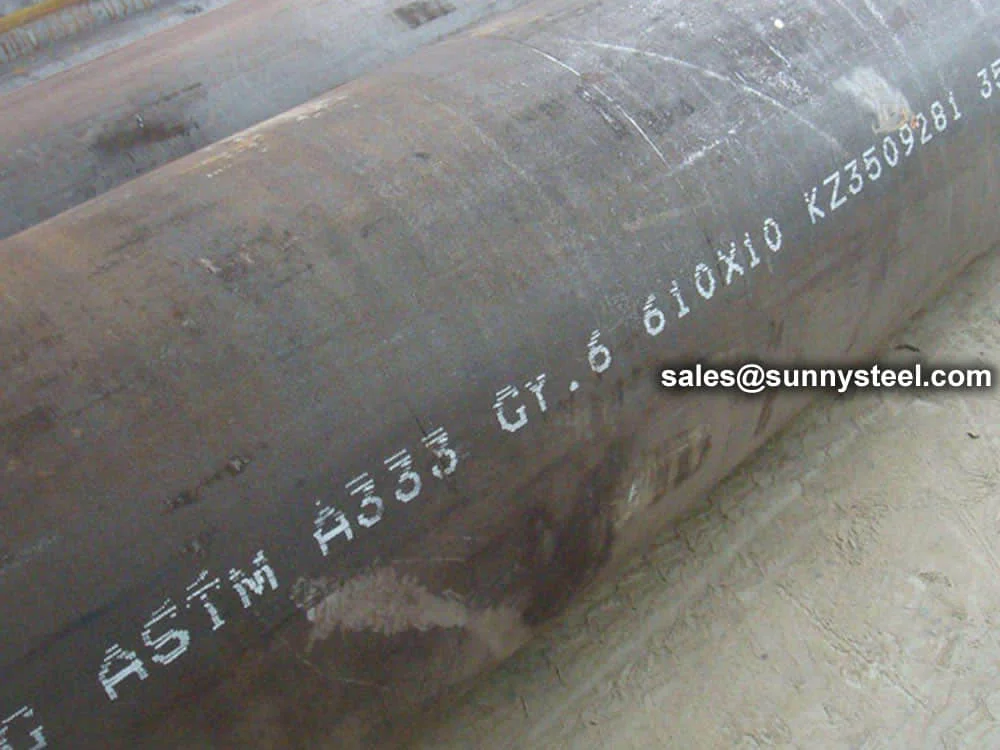

ASTM A333 Grade 6 Seamless Pipe is a premium low-temperature carbon steel pipe engineered for demanding applications, offering exceptional corrosion resistance and notch toughness at temperatures as low as -45°C (-50°F). Conforming to ASTM A333/ASME SA333 standards, this seamless pipe is ideal for boiler pipeline protection, oil and gas pipelines, petrochemical plants, and other industrial piping systems requiring reliability in extreme cold environments.

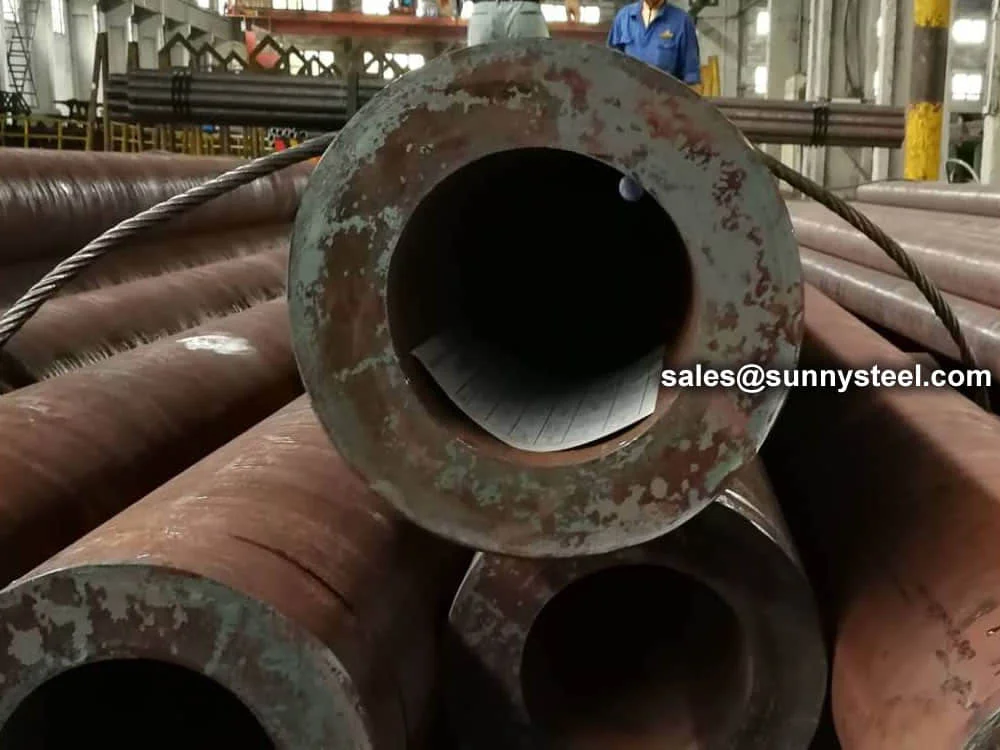

The ASTM A333 Grade 6 Seamless Pipe is manufactured through a seamless process, ensuring a uniform structure without welds, which enhances its durability under high-pressure and low-temperature conditions. Its composition, featuring low carbon and controlled manganese, provides excellent weldability and formability, making it suitable for bending, flanging, and fusion welding. The pipe undergoes specific heat treatment, such as normalization at 815°C (1500°F) or higher, to achieve optimal mechanical properties, ensuring resistance to brittle fracture in cold climates.

With a minimum tensile strength of 415 MPa and yield strength of 240 MPa, this low-temperature pipe offers robust performance for transporting fluids and gases in harsh environments. Its corrosion resistance makes it ideal for handling corrosive media in petrochemical applications, while its notch toughness ensures reliability in subsea drilling and refrigerated systems. The pipe is available in sizes from 1/8” to 48” (DN 6 to DN 1200), with wall thicknesses ranging from SCH 40 to SCH 160, and lengths up to 18 meters or customized to meet project needs.

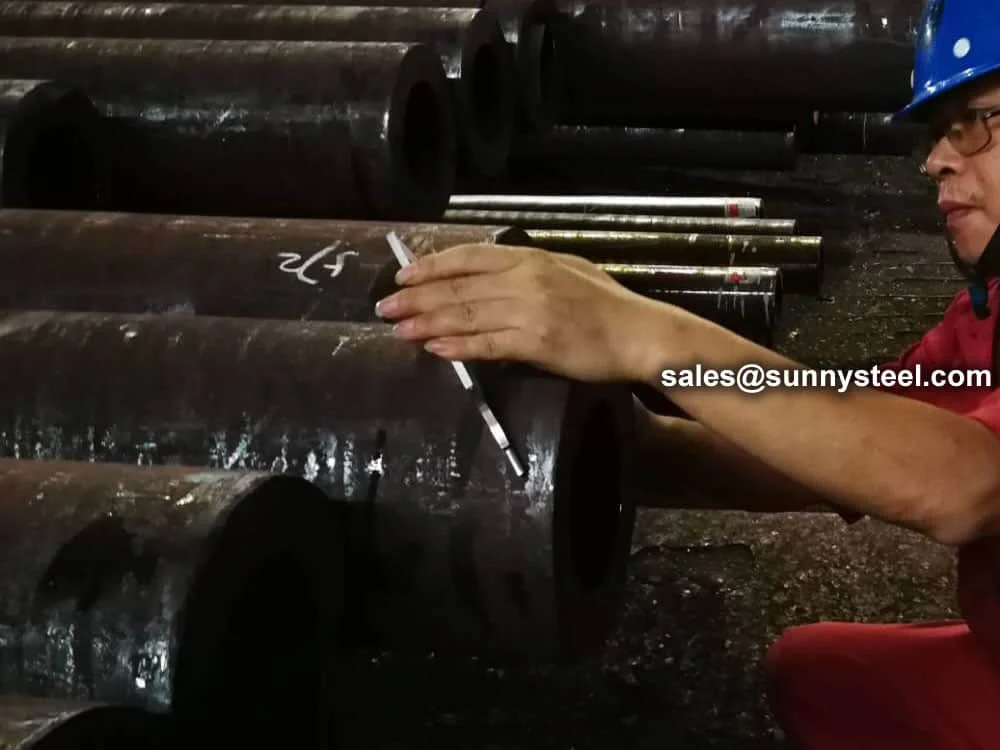

The ASTM A333 Grade 6 Seamless Pipe undergoes rigorous testing, including hydrostatic, nondestructive electric, and Charpy V-Notch impact tests, to ensure compliance with ASTM standards. Surface treatments like 3LPE, FBE, or galvanizing enhance its corrosion resistance, while plain or beveled ends facilitate easy installation. Compared to other grades, such as ASTM A106, Grade 6 is specifically designed for low-temperature service, offering superior toughness and reliability in cold environments.

This seamless pipe addresses critical challenges like pipeline wear, corrosion, and thermal stress in high-throughput industrial systems. Its seamless construction and advanced material properties make it a preferred choice for engineers seeking durable industrial piping solutions for extreme conditions. Whether used in boiler systems, LNG plants, or oil and gas pipelines, the ASTM A333 Grade 6 Seamless Pipe delivers unmatched performance, safety, and longevity.

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤ 0.30 |

| Manganese (Mn) | 0.29–1.06 |

| Phosphorus (P) | ≤ 0.025 |

| Sulfur (S) | ≤ 0.025 |

| Silicon (Si) | ≥ 0.10 |

| Nickel (Ni) | ≤ 0.40 |

| Chromium (Cr) | ≤ 0.30 |

| Copper (Cu) | ≤ 0.30 |

| Property | Value |

|---|---|

| Tensile Strength | ≥ 415 MPa |

| Yield Strength | ≥ 240 MPa |

| Elongation | ≥ 30 % |

| Impact Toughness | ≥ 27 J @ –100 °C |

| Hardness | ≤ 241 HBW |

| Standard | Pipes | Buttweld Fittings | Forged Steel Fittings | Valves | Bolts and Nuts |

|---|---|---|---|---|---|

| Low Temp Carbon Steel | A333 GR6 | A420 WPL6 | ASTM A350 LF2 | A352 LCB | A320 Gr L7 / A194 Gr 7 |

The equivalent grade to ASTM A333 GR6 is often EN 10216-4 P265NL or DIN 17173 TT St 35N. These grades share similar mechanical properties and are suitable for low-temperature service applications.

ASTM A333

Low temperature pipe refers to pipes specifically designed to withstand and operate effectively in environments with low temperatures, typically below 0°C (32°F).

These pipes are often used in industries such as oil and gas, petrochemicals, and refrigeration, where fluids need to be transported or stored at low temperatures. They are constructed from materials that can maintain their mechanical properties and structural integrity even in extremely cold conditions, ensuring the safe and efficient transportation of fluids. Additionally, low temperature pipes are insulated to prevent heat transfer and maintain the desired temperature of the fluid being transported.

Compared with austenitic stainless steel and duplex stainless steel, there are many comprehensive advantages of ferrite alloy steels for low temperature service, such as higher strength, better rigidity and lower expansion coefificient. There is not only better stability but aslo higher heat transfer efficiency. Tube & pipe for low-temperature service can be widely used in low temperature engineering. ASTM/ASME A/SA-333 Grades allow for cold temperature service to minus 150 degrees F. Material is always provided in the normalized condition at a minimum and Charpy Impact tested to a specific temperature range to assure compliance with the required service temperature.

Exceptional performance at temperatures down to -45°C with superior notch toughness and impact resistance.

Fine-grain structure with uniform carbide dispersion prevents brittle fracture in cryogenic conditions.

Economical alternative to exotic materials while providing reliable low-temperature performance.

Good weldability using conventional processes with minimal post-weld heat treatment requirements.

Precise control of chemical composition using electric arc furnaces with advanced ladle metallurgy techniques. Vacuum degassing reduces hydrogen content and eliminates inclusions.

Seamless pipes manufactured using hot piercing and rolling. Welded pipes produced using ERW or SAW processes with strict welding parameter controls.

Controlled heat treatment including normalizing at 815°C (1500°F), quench and temper, or stress relief to achieve optimal microstructure and properties.

Comprehensive testing including chemical analysis, mechanical testing, Charpy V-notch impact testing, hydrostatic testing, and non-destructive examination.

ASTM A333 Grade 6 Seamless Pipe is widely used in industries requiring excellent high-temperature, high-pressure, and corrosion-resistant performance.

Used in boilers, superheaters, and steam lines in thermal and nuclear power plants.

Ideal for hydrocarbon processing, ethylene cracking, and heat exchanger units.

Used in LNG pipelines, storage tanks, and vaporization equipment for cold media.

Ensures excellent thermal conductivity and corrosion resistance in cyclic operations.

Handles high-pressure oil and gas in extraction, refining, and transportation systems.

Resists acidic and corrosive environments in reactors, scrubbers, and distillation units.