Low-temperature Seamless Pipe For Cryogenic Applications

16mndg seamless steel pipe offers excellent low-temperature toughness and corrosion resistance for cryogenic pressure vessels and heat exchangers.

Low-temperature Seamless Pipe For Cryogenic Applications

16mndg seamless steel pipe offers excellent low-temperature toughness and corrosion resistance for cryogenic pressure vessels and heat exchangers.

The 16MnDG Steel Pipe is a seamless low-temperature pipe designed for exceptional performance in low-temperature service, offering superior notch toughness and corrosion resistance. Conforming to the GB/T 18984-2003 standard, this seamless steel pipe is engineered for cryogenic pressure vessel piping and low-temperature heat exchanger tubes, suitable for operating temperatures from -45°C to -195°C. Its composition, featuring 0.12-0.20% carbon, 0.8-1.6% silicon, and 0.60-0.90% manganese, ensures robust performance in harsh cryogenic environments, such as oil and gas pipelines, refrigeration systems, and chemical processing plants.

Manufactured through seamless processes, the 16MnDG Steel Pipe undergoes heat treatments such as normalizing or tempering to enhance its microstructure for low-temperature impact toughness. Available in sizes from 1/2” to 36” (NPS), with wall thicknesses from 3mm to 12mm (SCH 40 to XXS), and lengths from 3m to 18m or customized, it meets diverse project specifications. Surface coatings like 3LPE, FBE, or galvanizing improve corrosion resistance, while plain, beveled, or threaded ends ensure seamless integration into cryogenic piping systems.

The Seamless Steel Pipe is subjected to rigorous testing, including tensile, impact, hydrostatic, and nondestructive tests, to ensure compliance with GB/T 18984 standards. Its superior notch toughness, with enhanced impact toughness compared to standard 16Mn steel, makes it ideal for transporting fluids in extreme cold climates, preventing brittle fracture in cryogenic conditions down to -195°C. This makes it a preferred choice for low-temperature pressure vessels and heat exchanger systems.

Compared to standard 16Mn steel, the 16MnDG Steel Pipe has lower phosphorus and sulfur content, enhancing its tensile strength, elongation, and impact toughness for low-temperature applications. It is compatible with fittings and flanges designed for low-temperature service, ensuring seamless integration into complex cryogenic piping networks. Its versatility also extends to structural applications in cold environments, where durability and wear resistance are critical.

Engineered to address challenges like pipeline contraction and brittle failure in cryogenic conditions, the 16MnDG Steel Pipe provides a cost-effective, durable solution for engineers seeking reliable cryogenic piping for extreme environments. Its high-quality seamless construction ensures safety, longevity, and efficiency in demanding applications, including LNG plants and low-temperature industrial systems.

| Material | China (GB) | Former Soviet (ГОСТ) | USA (ASTM/SAE) | England (BS) | Japan (JIS) | France (NF) | Germany (DIN) |

|---|---|---|---|---|---|---|---|

| High‑Quality Carbon Structural Steel | 08F | 08КП | 1006 | 040A04 | S09CK | – | C10 |

| 10F 10 |

– | 1010 10,101,012 |

040A10 045M10 |

– S10C |

XC10 | C10, CK10 | |

| 15Mn/20Mn/30Mn Carbon Steel | 15Mn | 15Г | 080A17 | SB46 | XC12 | – | 14Mn4 |

| 20Mn | 20Г | 080A20 | – | XC18 | – | – | |

| 20Mn2 Alloy Steel | 20Mn2 | 20Г2 | 13201, 1321 | 150M19 | SMn420 | – | 20Mn5 |

| 15CrMo Alloy Steel | 15Cr | 15X | 5115 | 523M15 | SCr415(H) | 12C3 | 15Cr3 |

| 0Cr17Ni12Mo2 Stainless (Heat‑Resistant) |

0Cr17Ni12Mo2 | 08X17H13M2T | 316/S31600 | 316S16 | SUS316 | Z6CND17.12 | X5CrNiMo1810 |

Performs reliably at -45°C to -195°C for cryogenic applications.

Coatings like 3LPE enhance durability in harsh environments.

Prevents brittle fracture for safe fluid transport.

Uniform structure ensures high-pressure performance.

Long lifespan minimizes maintenance in cryogenic systems.

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.12-0.20 |

| Silicon (Si) | 0.8-1.6 |

| Manganese (Mn) | 0.60-0.90 |

| Phosphorus (P) | ≤0.025 |

| Sulfur (S) | ≤0.025 |

| Other Elements | ≤0.25 (Ni, Cr, Cu, etc.) |

| Property | Value |

|---|---|

| Tensile Strength, min (MPa) | ≥470 |

| Yield Strength, min (MPa) | ≥295 |

| Elongation, min (%) | ≥22 |

| Impact Toughness | Enhanced for cryogenic use |

| Temperature (°C) | Modulus of Elasticity (GPa) | Mean Coefficient of Thermal Expansion (10⁻⁶/°C, from 20 °C) |

Thermal Conductivity (W/m·°C) |

Specific Heat Capacity (J/kg·°C) |

Electrical Resistivity (Ω·mm²/m) |

Density (kg/dm³) |

Poisson's Ratio, ν |

|---|---|---|---|---|---|---|---|

| 31 | – | – | – | – | 0.24 | – | – |

| 468 | 231 | – | 13.3 | 131 | – | – | – |

| 623 | – | 12 | 12.2 | – | 331 | 432 | – |

| Grade | Standard | Region | Description |

|---|---|---|---|

| 09Mn2VDG | GB/T 18984 | China | Seamless steel pipe for low‑temperature pipeline |

| 06Ni3MoDG | GB/T 18984 | China | Seamless steel pipe for low‑temperature pipeline |

| 16MnDG | GB/T 18984 | China | Seamless steel pipe for low‑temperature pipeline |

| 10MnDG | GB/T 18984 | China | Seamless steel pipe for low‑temperature pipeline |

| 09DG | GB/T 18984 | China | Seamless steel pipe for low‑temperature pipeline |

| Grade | C | Mn | P (max) | S (max) | Si | Cr | Ni | Mo | V |

|---|---|---|---|---|---|---|---|---|---|

| 09Mn2VDG | ≤0.12 | 1.85 | 0.020 | 0.010 | 0.17–0.37 | – | – | – | ≤0.12 |

| 06Ni3MoDG | ≤0.08 | ≤0.95 | 0.015 | 0.008 | 0.17–0.37 | – | 2.50–3.70 | ≤0.05 | ≤0.05 |

| 16MnDG | 0.12–0.20 | 1.20–1.60 | ≤0.025 | ≤0.010 | 0.20–0.55 | – | – | – | – |

| 10MnDG | ≤0.13 | 1.35 | 0.020 | 0.010 | 0.17–0.37 | – | – | – | – |

| 09DG | ≤0.12 | 0.95 | 0.020 | 0.010 | 0.17–0.37 | – | – | – | – |

| Grade | Rp₀.₂ (≥ MPa) | Rₘ Range (MPa) | Elongation ≥ (%) | Impact ≥ (J) |

|---|---|---|---|---|

| 09Mn2VDG | 300 | ≥450 | – | – |

| 06Ni3MoDG | 250 | 455 | – | – |

| 16MnDG | 325 | 490–665 | 30 | – |

| 10MnDG | 240 | 400 | – | – |

| 09DG | 210 | 385 | – | – |

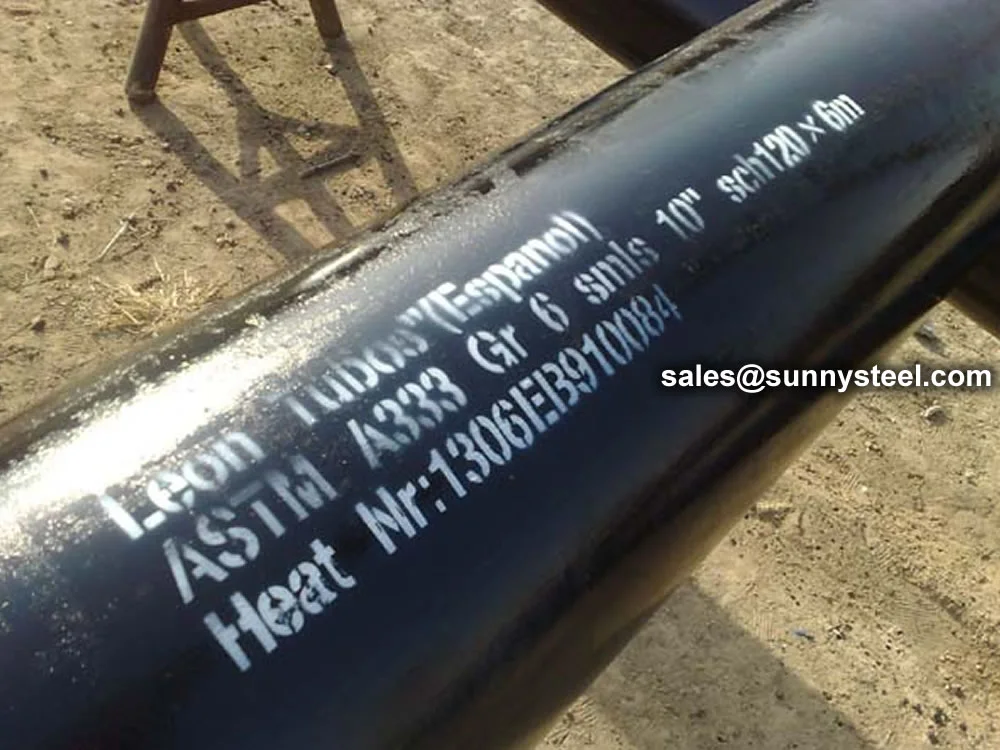

| Feature | 16MnDG | 16Mn | ASTM A333 Grade 6 |

|---|---|---|---|

| Material Type | Low Alloy Steel | Low Alloy Steel | Carbon Steel |

| Temperature Range | Low (-45°C to -195°C) | Ambient to High | Low (-45°C to ambient) |

| Notch Toughness | Superior (Enhanced for cryogenic) | Moderate | Superior (18 J at -45°C) |

| Corrosion Resistance | Good (With coatings) | Moderate | Good (With coatings) |

| Applications | Cryogenic, Pressure Vessels, Heat Exchangers | Structural, Boilers, General Piping | Oil/Gas, Cryogenic, Chemical |

| Tensile Strength (MPa) | ≥470 | 470-630 | 415 (min) |

| Yield Strength (MPa) | ≥295 | ≥343 | 240 (min) |

| Key Advantage | Extreme low-temp toughness | High strength for structural use | Low-temp toughness |

16MnDG Seamless Steel Pipe is widely used in industries requiring excellent high-temperature, high-pressure, and corrosion-resistant performance.

Used in boilers, superheaters, and steam lines in thermal and nuclear power plants.

Ideal for hydrocarbon processing, ethylene cracking, and heat exchanger units.

Used in LNG pipelines, storage tanks, and vaporization equipment for cold media.

Ensures excellent thermal conductivity and corrosion resistance in cyclic operations.

Handles high-pressure oil and gas in extraction, refining, and transportation systems.

Resists acidic and corrosive environments in reactors, scrubbers, and distillation units.

Astm a333 grade 6 pipe offers excellent toughness ...

Astm a333 grade 3 seamless pipe is ideal for low-t...