Alloy steel pipes, often called Chrome Moly pipes, are vital for industries requiring superior strength, corrosion resistance, and high-temperature performance.

Our Alloy Steel Pipes Stock offers an extensive inventory of high-quality alloy steel pipes ready for immediate delivery. These pipes are manufactured from premium alloy steels, designed to provide superior strength, durability, and corrosion resistance across a variety of industrial applications.

The stocked alloy steel pipes are suitable for demanding environments including petrochemical plants, power generation facilities, construction projects, and heavy machinery manufacturing. Their seamless or welded construction ensures high reliability and performance under high pressure and temperature conditions.

Our inventory includes a range of grades such as chrome-molybdenum steels, stainless alloys, and carbon-alloy blends, providing solutions tailored to specific application requirements. These pipes are rigorously tested to meet international standards including ASTM, ASME, and API, guaranteeing consistent quality and performance.

With flexible sizing options and various surface finishes, our alloy steel pipes stock can fulfill urgent procurement needs, reducing lead times and project delays. Whether you require pipes for industrial pipe protection, boiler systems, or other critical infrastructure, our stocked pipes provide reliable and cost-effective solutions.

Alloy steel pipes are manufactured by alloying steel with chromium, molybdenum, nickel, and other elements, significantly improving mechanical properties such as strength, toughness, wear and corrosion resistance, especially under high temperature and pressure.

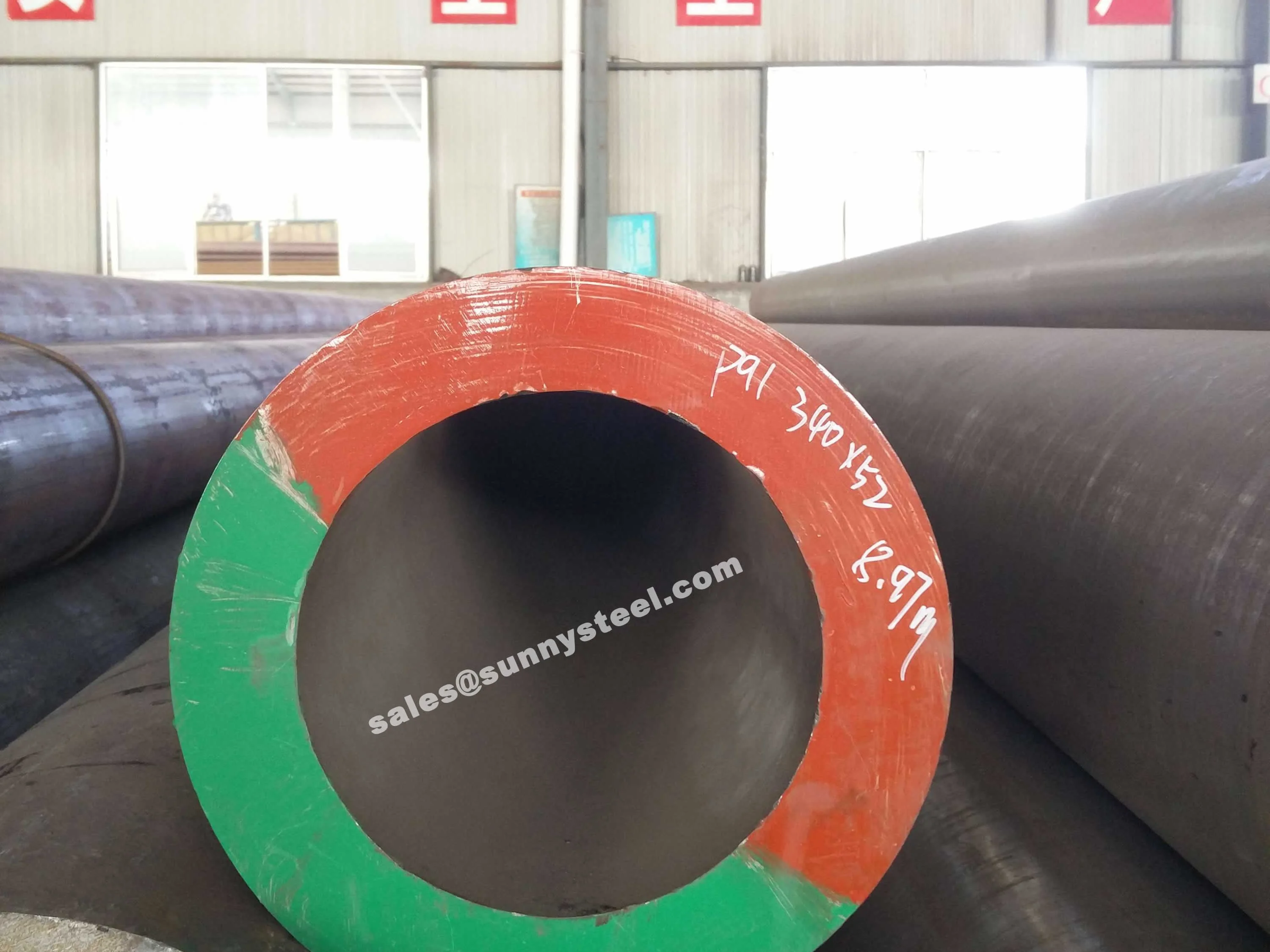

Widely used in power plants, refineries, and petrochemical industries, specific grades like ASTM A335 P91 and P92 offer excellent creep strength and resistance to softening, making them suitable for the most demanding applications.

Available in a wide range of sizes and standards including ASTM A213 and ASTM A335, both seamless and welded, these pipes meet diverse industrial specifications.

Their recyclability, energy efficiency, and environmental compliance make alloy steel pipes a sustainable choice. Growing industrialization, especially in regions like China, drives increasing demand for these high-performance pipes.

Frequently Asked Questions

Alloy steel pipes are steel pipes alloyed with elements like chromium, molybdenum, and nickel to enhance their strength, corrosion resistance, and ability to withstand high temperatures.

They are commonly used in power generation, petrochemical plants, refineries, oil and gas industries, and chemical processing, especially where high temperature and pressure conditions exist.

Popular grades include ASTM A335 P91, P92, ASTM A213 T11, T22, and others designed to withstand elevated temperatures and corrosive environments.

Yes, alloy steel pipes are highly recyclable and support energy-efficient industrial applications, aligning with modern environmental standards.

Molybdenum enhances creep strength, improves resistance to softening at high temperatures, and increases corrosion resistance, making pipes more durable in harsh environments.