Expansion Joints

Expansion Joints

Weldolets provide strong, corrosion-resistant branch connections for industrial piping systems. Ideal for boiler pipeline protection and oil/gas applications, they ensure reliable, leak-free performance.

Expansion Joints

Weldolets provide strong, corrosion-resistant branch connections for industrial piping systems. Ideal for boiler pipeline protection and oil/gas applications, they ensure reliable, leak-free performance.

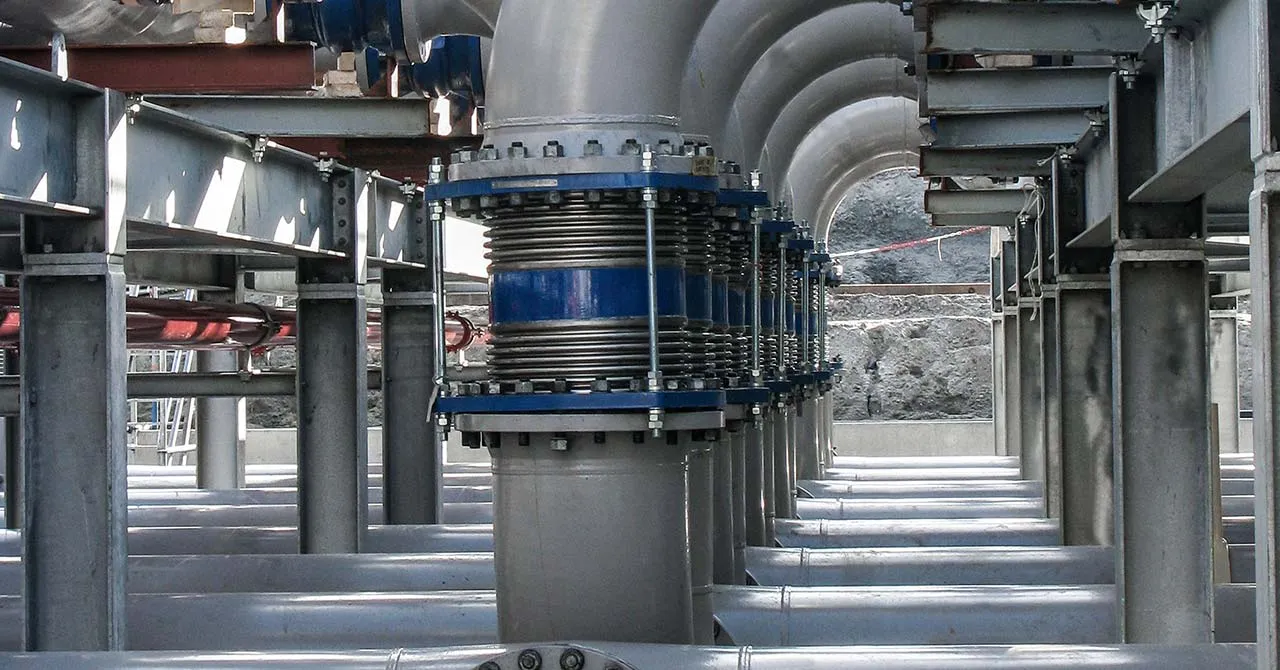

Expansion Joints are critical components in industrial piping systems, designed to absorb thermal expansion, vibrations, and misalignments, ensuring system integrity and longevity. Compliant with standards like EJMA and ASME B31.3, these flexible connectors are used in industries such as oil and gas, petrochemical, power generation, and water treatment. Made from materials like stainless steel (316L), rubber (EPDM, Neoprene), PTFE, or fabric, they provide excellent corrosion resistance and adaptability for boiler pipeline protection and other high-stress applications.

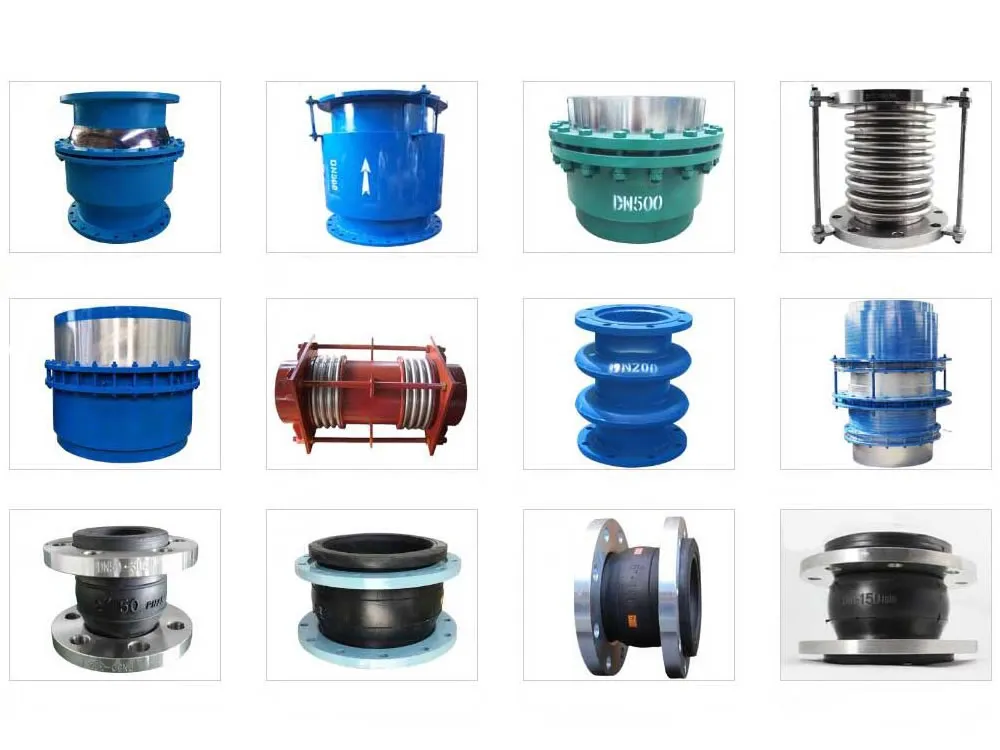

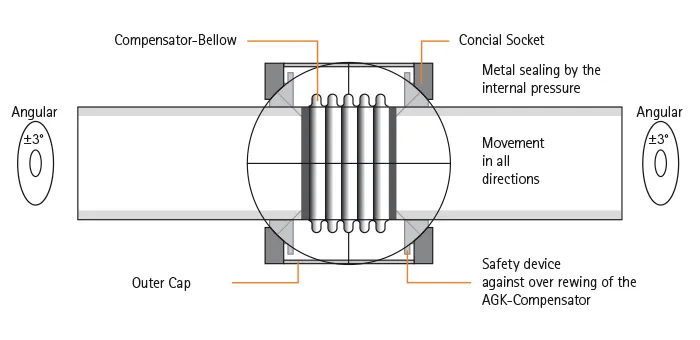

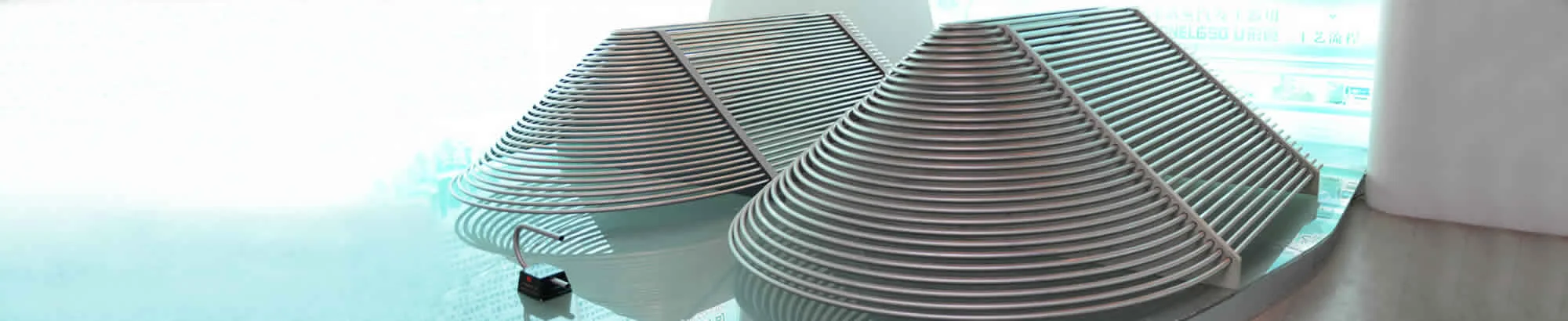

Expansion joints are manufactured in various types, including metallic bellows, rubber, PTFE-lined, and fabric joints, to suit specific applications. Available in sizes from 2” to 60” and pressure ratings up to 500 psi, they handle temperatures from -196°C (cryogenic) to 875°C (high-temperature exhaust). The bellows design, often with multiple convolutions, allows for axial, lateral, and angular movements, reducing stress on pipes and connected equipment like pumps and turbines. Surface treatments such as 3LPE or FBE coatings enhance corrosion resistance, making them suitable for handling corrosive media in chemical plants or abrasive slurries in mining.

These joints undergo rigorous testing, including hydrostatic, pneumatic, and non-destructive tests (e.g., radiographic, ultrasonic), to ensure compliance with industry standards. With tensile strengths varying by material (e.g., 515 MPa for stainless steel 316L), they withstand high-pressure and high-temperature conditions, critical for boiler pipeline protection. The design minimizes anchor loads and prevents pipeline buckling, offering a compact alternative to pipe loops. Accessories like liners, covers, tie rods, and control rods enhance performance, ensuring stability and durability in dynamic systems.

Compared to alternatives like pipe loops or slip joints, expansion joints provide superior flexibility and space efficiency. Metallic bellows excel in high-temperature applications, while rubber joints are ideal for vibration control in HVAC systems or near rotating equipment. PTFE-lined joints offer unmatched resistance to corrosive chemicals, and fabric joints suit low-pressure ducting systems. Their versatility extends to applications like LNG terminals, nuclear power plants, and wastewater treatment, where they mitigate thermal stress and mechanical vibrations.

Expansion joints address critical challenges like pipeline wear, thermal expansion, and corrosion in demanding industrial environments. Their robust construction and material versatility make them essential for engineers seeking reliable solutions for industrial piping. Whether used in high-pressure steam systems or corrosive chemical pipelines, these joints deliver safety, performance, and extended service life.

| Feature | Expansion Joints | Pipe Loops | Slip Joints |

|---|---|---|---|

| Material Type | Stainless Steel/Rubber/PTFE | Carbon/Stainless Steel | Carbon/Stainless Steel |

| Movement Type | Axial, Lateral, Angular | Axial, Limited Lateral | Axial Only |

| Corrosion Resistance | Excellent (Material-dependent) | Moderate (Coatings needed) | Moderate (Seals needed) |

| Applications | Boilers, HVAC, Chemical Plants | Steam Systems, Outdoor | Steam, High-Pressure |

| Tensile Strength (MPa) | 10-515 (Material-dependent) | 485-515 | 485-515 |

| Space Requirement | Low (Compact) | High (Large loops) | Moderate |

| Key Advantage | Versatile movement, vibration control | Simple design | Repackable in service |

Materials like PTFE and stainless steel resist harsh chemicals.

Absorbs shocks and vibrations, protecting equipment.

Manages pipe expansion in high-temperature systems.

Compact design reduces system footprint.

Resists wear and extends pipeline life.

Reduces maintenance and downtime costs.

Expansion joints, also known as expansion bellows, flexible joints, compensators, or movement joints, are devices containing a bellows membrane designed to absorb dimensional changes, such as those caused by thermal expansion or contraction in pipelines, ducts, or vessels. They accommodate movements like vibration, misalignment, or building settlement, ensuring the integrity of industrial piping systems.

Expansion joints are devices containing a bellows membrane that are designed to absorb dimensional changes, such as those that occur due to thermal expansion or contraction of a pipeline, duct or vessel. The need to solve the problems of thermal expansion are not unique to anyone industry therefore expansion joints are used in a wide variety of market sectors specifically where there is a need to control the movement of pipelines due to changes in temperature. Thermal expansion problems can be solved where the natural flexing of the pipe is practical or where it is possible to install pipe loops however this is not always possible due to economic reasons or the design of modern structures are not capable of taking the loads of flexing pipework. In these situations the design engineer must seek an expansion joint solution.

Expansion joints come in two forms either restrained or unrestrained styles and although the bellows membrane incorporated in both styles look similar it is of great importance to recognize that they are used for entirely different applications.

Expansion joints can be made from a variety of materials depending on the application. Metal bellows are one of the most common and useful types of expansion joint, but rubber, fabric and plastics (such as PTFE) are also used in various circumstances. To ensure that the correct type of expansion joint is used for your application, it is essential that an engineer with experience in this field is consulted prior to implementation.

Delivery

Inner plastic film packing, outer standard export wooden case packing.

Courier company transport, air freight and sea transport. It depends on your actual order details and quantity.

Expansion Joints are essential in industries requiring flexible, corrosion-resistant solutions for thermal expansion and vibration control in piping systems.

Absorbs thermal expansion in pipelines and refineries.

Handles corrosive media and vibrations.

Protects boilers and turbines from thermal stress.

Ensures leak-free operation in piping systems.

Manages cryogenic temperatures and vibrations.

Reduces noise and vibration in piping.

Pipe flanges are basically plates or rings used to...

A buttweld pipe fitting is a weldable component us...

U bend tubes are meticulously crafted for heat exc...

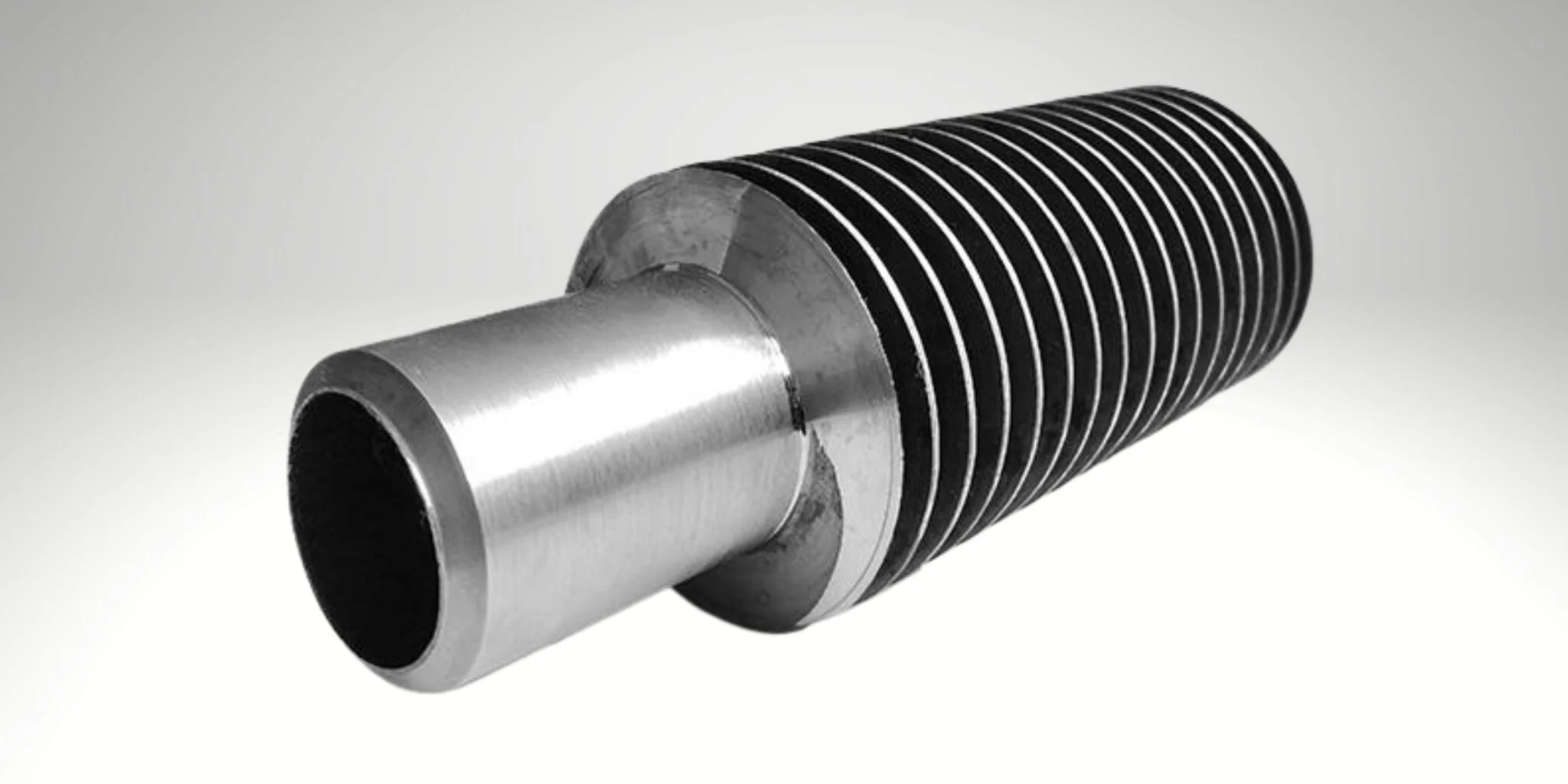

Fin tubes are specialized heat exchanger component...

Industrial valves are critical devices used to con...

Pipe couplings are essential fittings for connecti...