Boiler And Pressure Applications

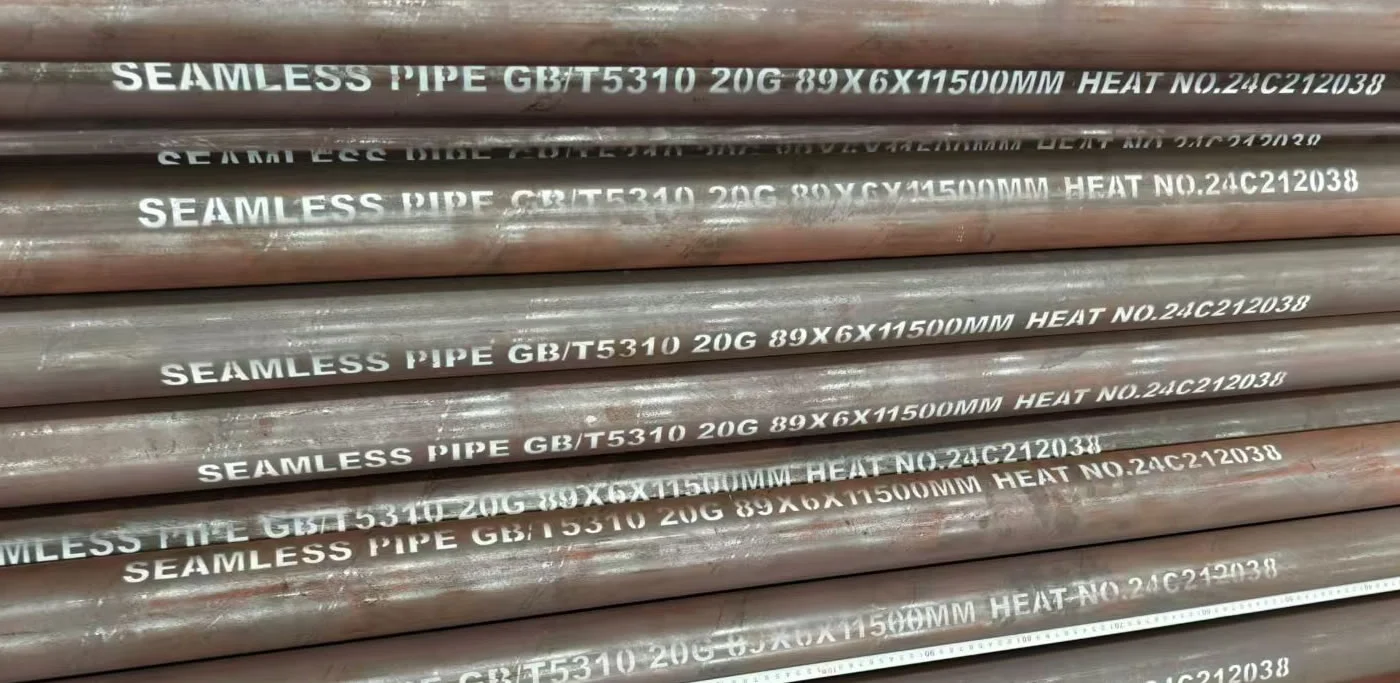

20g seamless steel pipe is a high-grade carbon steel tube ideal for high-temperature boilers and pressure vessels.

Boiler And Pressure Applications

20g seamless steel pipe is a high-grade carbon steel tube ideal for high-temperature boilers and pressure vessels. excellent strength and weldability.

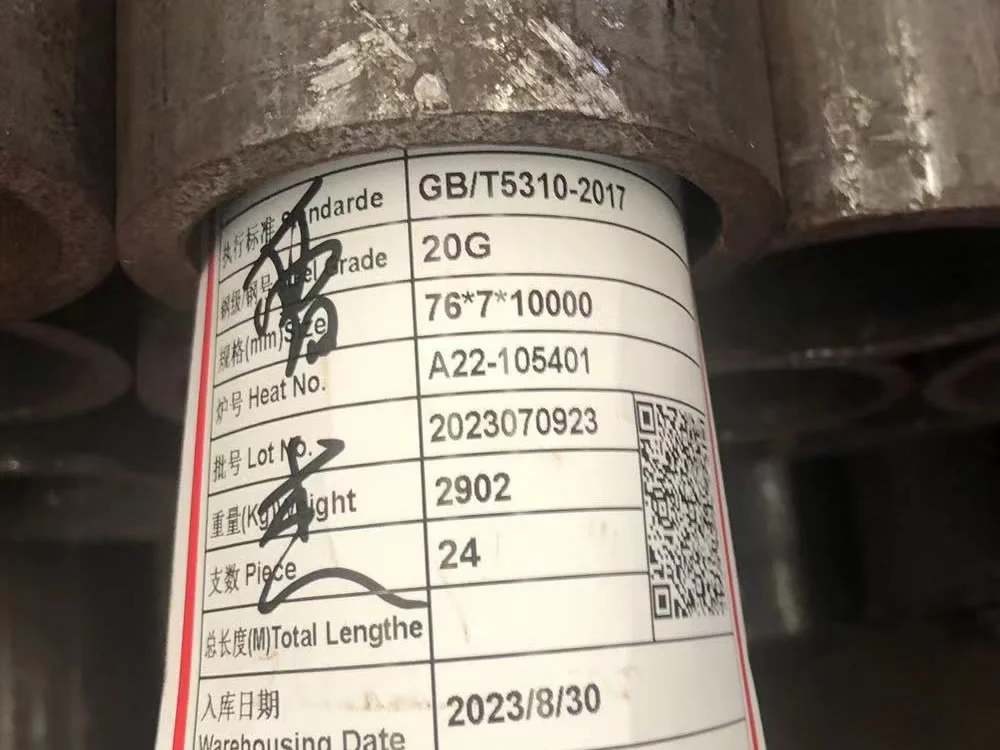

20G Seamless Pipe is a high-quality carbon steel pipe designed for excellent strength, toughness, and corrosion resistance in low and medium-pressure boiler applications. Conforming to the Chinese GB/T 5310-2017 standard, this pipe is composed of 0.17-0.23% carbon and 0.35-0.65% manganese, making it ideal for boiler pipeline protection in power plants, steam pipelines, and industrial piping systems operating at temperatures up to 450°C. Its seamless construction ensures superior durability and reliability under moderate pressure conditions.

The 20G Seamless Pipe is manufactured through hot-rolling or cold-drawing processes, typically delivered in a normalized or normalized-and-tempered state to optimize mechanical properties. The manganese content enhances strength and toughness, while the low carbon content ensures good weldability and formability, making it suitable for boiler pipeline protection in economizers, water walls, and low-pressure superheaters. Available in sizes from 10mm to 1200mm OD, with wall thicknesses from 2mm to 100mm, and lengths up to 12 meters or customized, it meets diverse project requirements.

The Seamless Carbon Steel Pipes undergo rigorous testing, including tensile, flattening, flaring, and hydrostatic tests, to ensure compliance with GB/T 5310 standards. With a tensile strength of 410-550 MPa and a minimum yield strength of 245 MPa, the 20G pipe offers reliable resistance to mechanical stress and moderate corrosion, ideal for handling steam and water in boiler systems. Surface treatments such as black varnish, galvanizing, or 3LPE coatings enhance corrosion resistance, while plain or beveled ends facilitate seamless integration into industrial piping systems.

Compared to alloy steel grades like 15CrMoG or 16Mn (Q345), the 20G Seamless Pipe has lower alloy content, making it more cost-effective for applications not requiring high-temperature or high-pressure resistance. Unlike 12Cr1MoVG, which is optimized for creep resistance at 580°C, 20G is suited for lower-temperature boiler components (up to 450°C). Its excellent weldability (carbon equivalent ~0.38) requires minimal preheating, making it easier to fabricate than higher-alloy grades like ASTM A335 P11. This makes it a preferred choice for low-pressure boilers, heat exchangers, and general-purpose industrial piping.

Engineered to address challenges like pipeline wear, corrosion, and mechanical stress, the 20G Seamless Pipe delivers reliable performance in low and medium-pressure industrial systems. Its robust carbon steel composition and seamless construction make it a cost-effective choice for engineers seeking durable industrial piping solutions for boiler and structural applications, ensuring safety, longevity, and efficiency in carbon steel pipe applications.

Tensile strength of 410-550 MPa for reliable performance.

Coatings ensure durability in moderate environments.

Low carbon content ensures easy welding with minimal preheating.

Uniform construction for reliable pressure applications.

Long lifespan reduces maintenance costs.

Ideal for boilers, heat exchangers, and industrial piping.

| Feature | 20G | 16Mn (Q345) | 15CrMoG |

|---|---|---|---|

| Material Type | Carbon Steel | Low Alloy Steel | Alloy Steel |

| Carbon Content | 0.17-0.23% | 0.12-0.20% | 0.12-0.18% |

| Manganese Content | 0.35-0.65% | 0.70-1.00% | 0.40-0.70% |

| Chromium Content | ≤0.25% | ≤0.30% | 0.80-1.10% |

| Temperature Range | Up to 450°C | Up to 350°C | Up to 550°C |

| Corrosion Resistance | Moderate (With coatings) | Moderate (With coatings) | Excellent (With coatings) |

| Applications | Low-Pressure Boilers, Pipelines | Pressure Vessels, Structures | Boilers, Petrochemical |

| Tensile Strength (MPa) | 410-550 | 470-630 | 440-640 |

| Yield Strength (MPa) | 245 (min) | 345 (min) | 235 (min) |

| Key Advantage | Excellent weldability | High strength, weldability | Balanced high-temp strength |

| W.T. (mm) | Diameter (D, mm) | Tolerance |

|---|---|---|

| - | +15% (+0.48mm min) | |

| - | -10% (+0.32mm min) | |

| 3.5–20 | - | +15%, -10% |

| >20 | D | ±10% |

| D≥219 | +12.5%, -10% |

| Column 1 | Column 2 | Column 3 | Column 4 |

|---|---|---|---|

| 83*13 | 127*10 | 168*20 | 245*27 |

| 83*14 | 127*17 | 168*32 | 245*32 |

| 89*16 | 133*16 | 180*21 | 273*27 |

| 95*9.2 | 133*16 | 180*22 | 273*30 |

| 95*10 | 133*22 | 180*25 | 273*36 |

| 95*15 | 140*18 | 180*40 | 299*30 |

| 102*14 | 146*14 | 194*21 | 325*30 |

| 114*9.2 | 152*17 | 203*26 | 377*35 |

| 114*10 | 159*16 | 219*22 | - |

| 114*19 | 159*21 | 219*25 | - |

20#: General-purpose use in structural parts, fluid transport, low/medium pressure boilers.

20G: Specialized for high-pressure boilers, superheaters, heat exchangers and pressure vessels.

20#: Plain carbon steel with standard carbon and manganese content.

20G: Contains trace alloying elements for improved high-temperature and oxidation resistance.

20#: Good ductility, plasticity, and strength; suitable for cold forming.

20G: Higher creep strength, excellent dimensional stability under stress and heat.

20#: Easy to weld and machine; best with arc and resistance welding.

20G: Requires more precise welding conditions due to critical service applications.

20#: Suitable for moderate pressure and temperature ranges.

20G: High-temperature and high-pressure resistant; ideal for steam and boiler systems.

20#: Widely available and lower in cost, suitable for general industries.

20G: Higher cost due to precise alloying and application-specific quality standards.

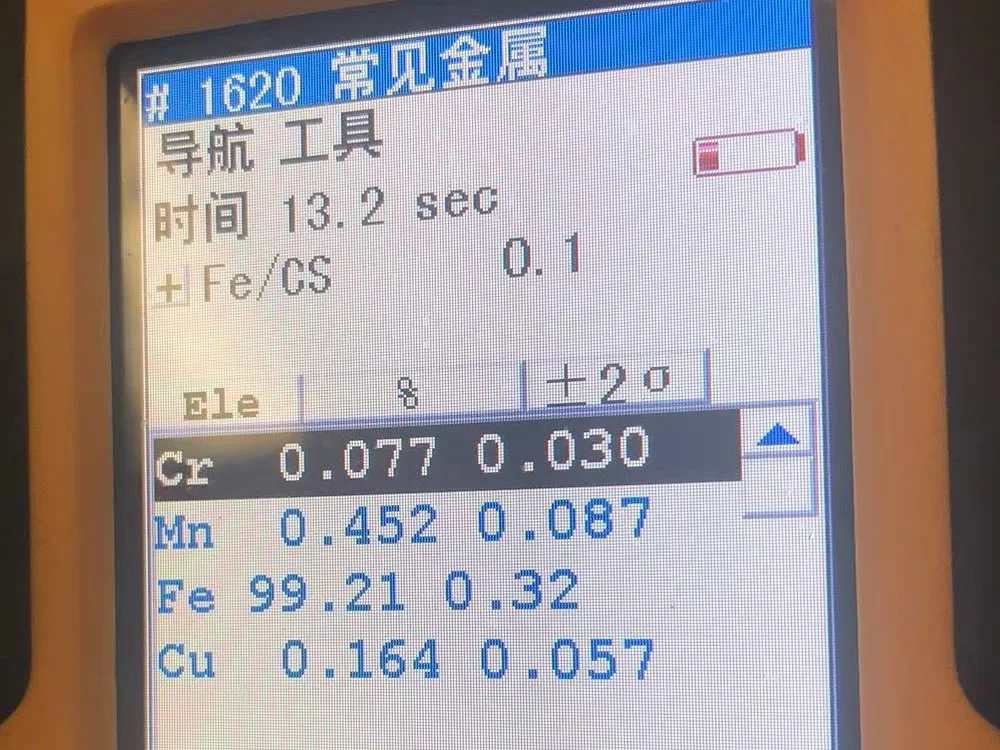

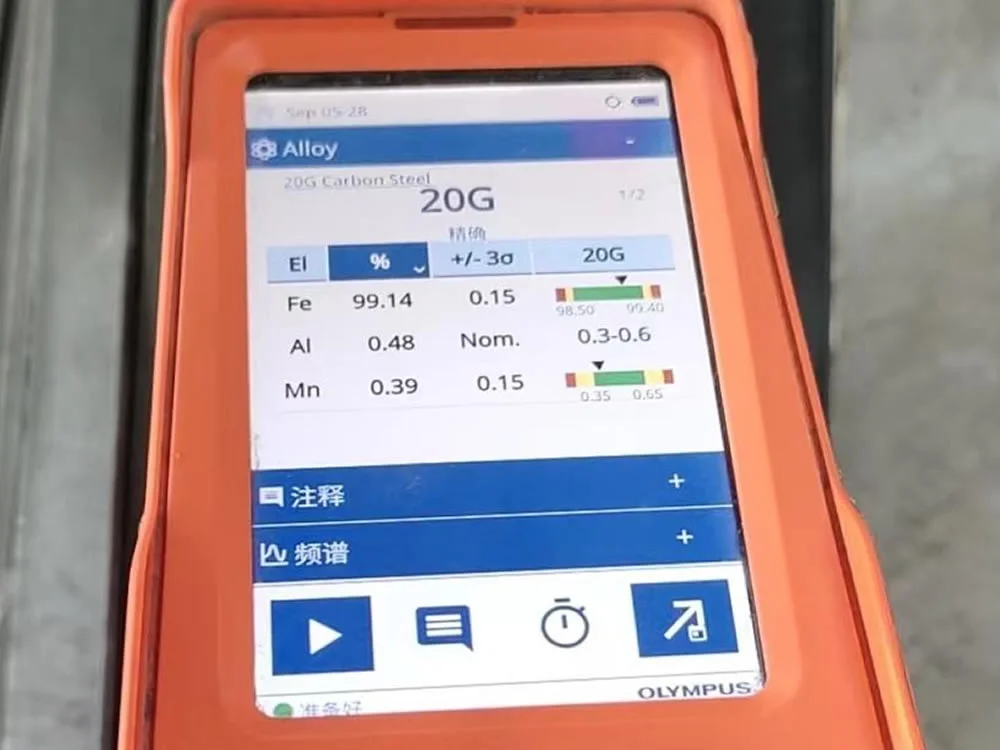

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.17-0.23 |

| Silicon (Si) | 0.17-0.37 |

| Manganese (Mn) | 0.35-0.65 |

| Phosphorus (P) | ≤0.035 |

| Sulfur (S) | ≤0.035 |

| Chromium (Cr) | ≤0.25 |

| Nickel (Ni) | ≤0.25 |

| Copper (Cu) | ≤0.25 |

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 410-550 |

| Yield Strength, min (MPa) | 245 |

| Elongation, min (%) | 24 |

| Impact Toughness (J) | ≥27 (at 20°C) |

20G seamless steel pipe is widely used in high-temperature and high-pressure systems, especially in thermal power generation, petrochemical engineering, and heat transfer equipment.

Used as superheater, reheater, and waterwall tubes in boilers, handling extreme temperatures and pressures in thermal power plants.

Facilitates thermal energy transfer between fluids in industrial systems, enhancing overall process efficiency.

Used in refineries for transporting high-temp and high-pressure fluids, ensuring safety and performance in critical systems.

15crmog seamless pipe offers high-temperature stre...

Wb36 seamless pipe offers high strength and creep ...

Astm a335 p9 seamless pipe offers high-temperature...

Astm a333 grade 6 seamless pipe offers low-tempera...

Astm a335 p11 alloy steel pipe delivers strength a...

12cr1movg seamless pipe offers high-temperature st...