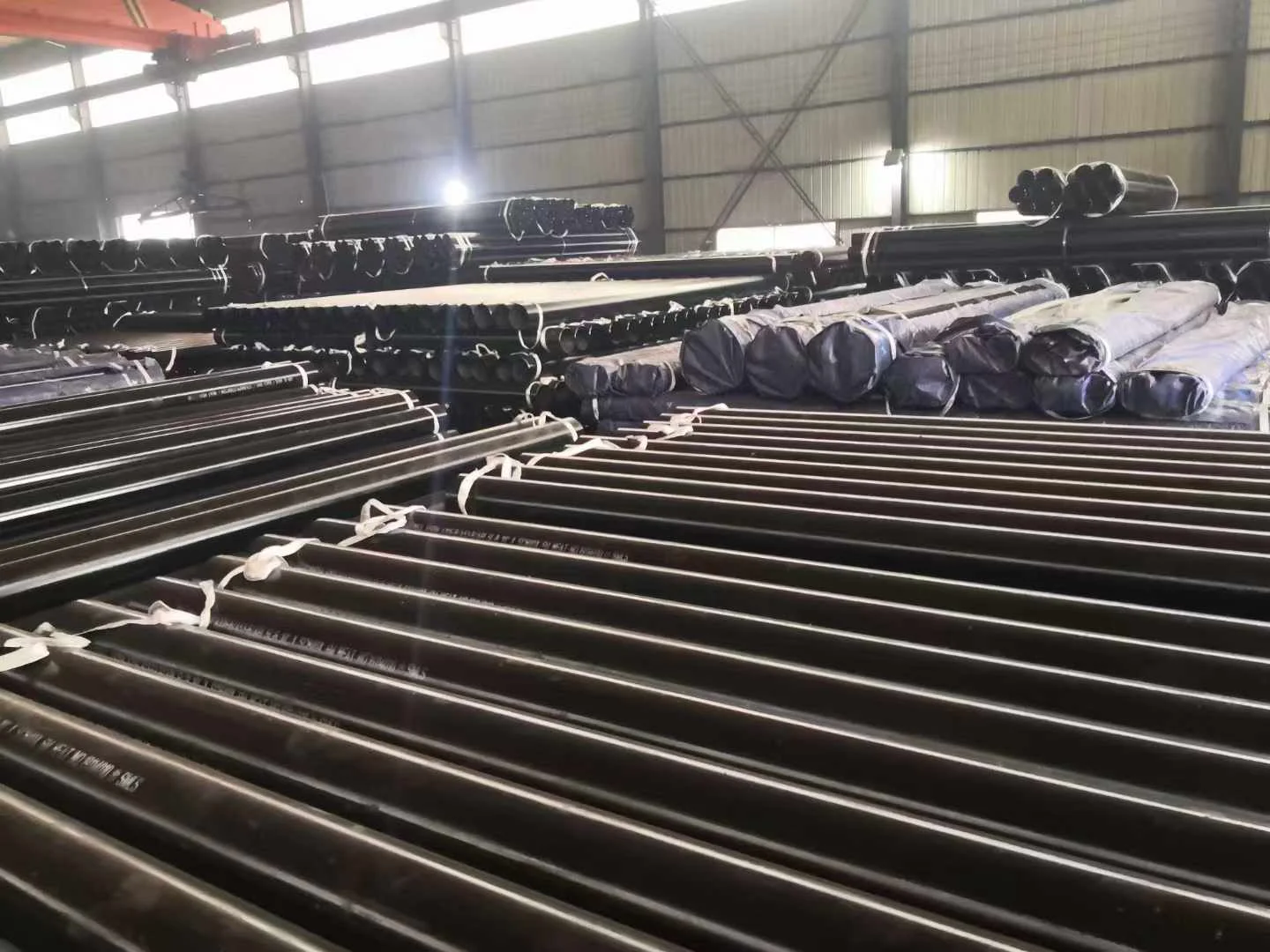

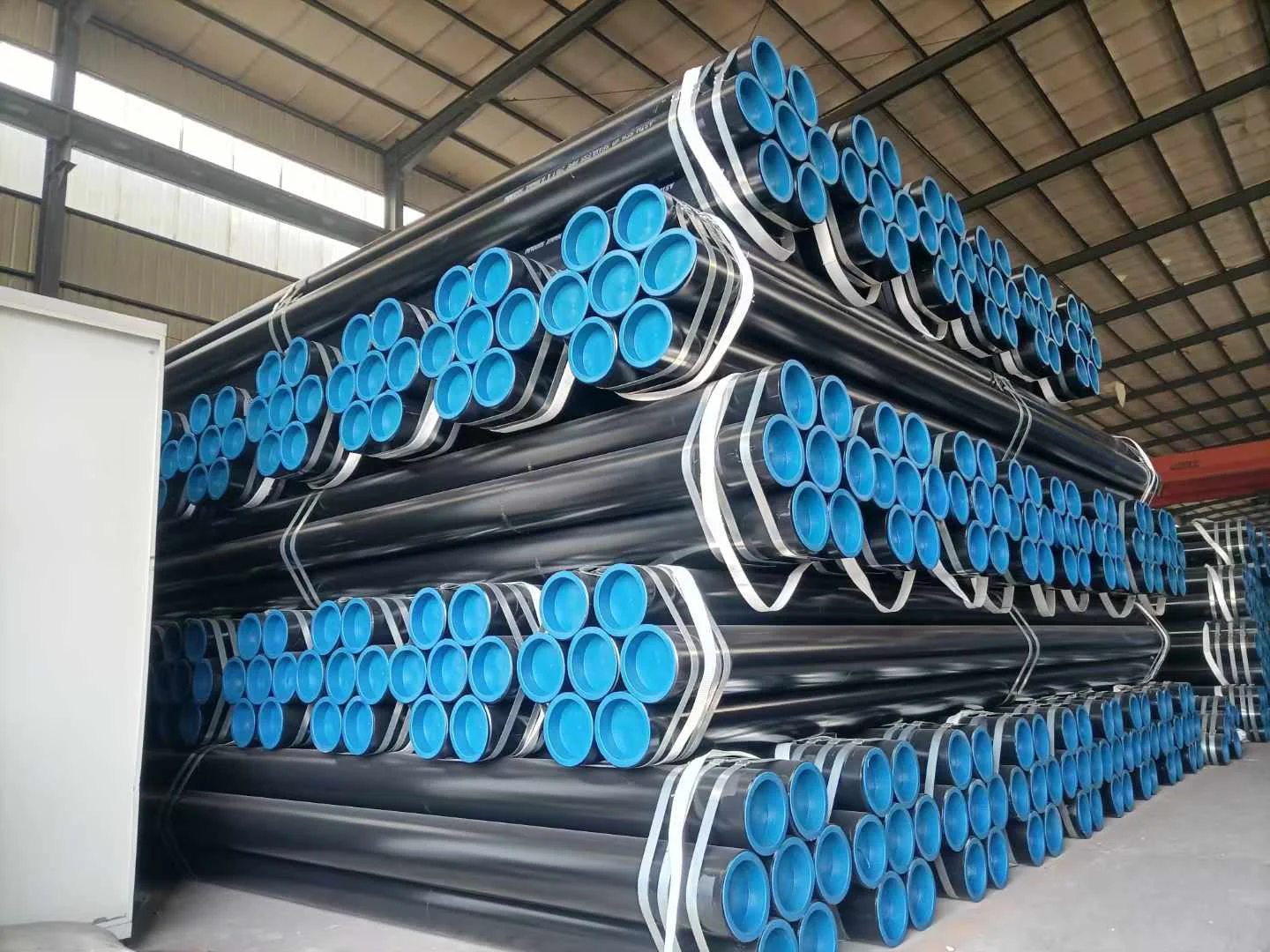

Astm A53 Steel Pipe

Astm a53 steel pipe meets stringent technical requirements, offering reliable strength, weldability, and corrosion resistance for steam, water, gas, and structural applications.

Astm A53 Steel Pipe

Astm a53 steel pipe meets stringent technical requirements, offering reliable strength, weldability, and corrosion resistance for steam, water, gas, and structural applications.

ASTM A53 steel pipe is a versatile carbon steel pipe used for mechanical, pressure, and structural applications. It is suitable for steam, water, gas, and air lines and comes in three types: seamless (Type S), electric-resistance welded (Type E), and furnace-welded (Type F).

It is available in Grades A and B, with Grade B offering higher strength (tensile ≥ 60,000 psi/415 MPa, yield ≥ 35,000 psi/240 MPa).

ASTM A53 Steel Pipe is a versatile carbon steel pipe designed for mechanical and pressure applications, offering superior corrosion resistance and durability. Conforming to the ASTM A53/ASME SA53 specification, this pipe is available in seamless (Type S), electric-resistance-welded (Type E), and furnace-butt-welded (Type F) variants in Grades A and B. It is ideal for industrial piping systems, including steam, water, gas, and air lines, as well as boiler pipeline protection in power generation, oil and gas, and construction industries.

The ASTM A53 Steel Pipe is manufactured using high-quality carbon steel through seamless or welded processes, ensuring reliability in low to medium-pressure environments. Its hot-dipped galvanized coating enhances corrosion resistance, making it suitable for harsh environments where pipelines are exposed to moisture or corrosive substances. Available in nominal pipe sizes (NPS) from 1/8” to 26” (DN 6 to DN 650) and schedules like 10, 40, STD, XS, and XXS, it meets diverse project needs. The pipe supports welding, bending, and flanging (except Type F), with Grade A offering better weldability and Grade B providing higher strength for demanding applications.

Rigorous testing ensures compliance with ASTM A53 standards, including hydrostatic, tensile, flattening, and nondestructive tests. The pipe’s abrasion resistance supports the transport of abrasive materials, while its galvanized variants excel in outdoor or high-moisture settings. Surface treatments like black lacquer or galvanizing, along with plain or beveled ends, facilitate easy installation in industrial piping systems. Its cost-effectiveness and versatility make it a preferred choice for engineers seeking reliable solutions for pipeline wear and corrosion challenges.

The ASTM A53 Steel Pipe is widely used in boiler systems, structural frameworks, and general-purpose piping due to its balanced strength and corrosion resistance. It addresses critical issues like pipeline wear, thermal stress, and corrosion in high-throughput industrial systems, ensuring safety and longevity. Whether for oil and gas pipelines or water distribution, this carbon steel pipe delivers unmatched performance and durability.

| Type | Grade | Element Max Content (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | P | S | Cu | Ni | Cr | Mo | V | ||

| Type S (seamless) |

A | 0.25 | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| B | 0.30* | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 | |

| Type E (ERW) |

A | 0.25 | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| B | 0.30* | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 | |

| Type F (Furnace welded) |

A | 0.30 | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

*If carbon is below 0.01% under max, allowed Mn increase by 0.06% up to 1.65% (not for SA53)

Mechanical Properties of ASTM A53 (Seamless & ERW)

Values based on ASTM A53/ASME SA53 standard :contentReference[oaicite:1]{index=1}

| DN | O. D. | W. T. | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inch | mm | SCH5S | SCH10S | SCH10 | SCH20 | SCH30 | SCH40 | SCH60 | SCH80 | SCH100 | SCH120 | SCH140 | SCH160 | STD | XS | XXS | |

| 50 | 2″ | 60.3 | 1.65 | 2.77 | – | – | – | 3.91 | – | 5.54 | – | – | – | 8.74 | 3.91 | 5.54 | 11.07 |

| 65 | 2 1/2″ | 73 | 2.11 | 3.05 | – | – | – | 5.16 | – | 7.01 | – | – | – | 9.53 | 5.16 | 7.01 | 14.02 |

| 80 | 3″ | 88.9 | 2.11 | 3.05 | – | – | – | 5.49 | – | 7.62 | – | – | – | 11.13 | 5.49 | 7.52 | 15.24 |

| 90 | 3 1/2″ | 101.6 | 2.11 | 3.05 | – | – | – | 5.74 | – | 8.08 | – | – | – | – | 5.74 | 8.08 | – |

| 100 | 4″ | 114.3 | 2.11 | 3.05 | – | – | – | 6.02 | – | 8.58 | – | 11.13 | – | 13.49 | 6.02 | 8.56 | 17.12 |

| 125 | 5″ | 141.3 | 2.77 | 3.4 | – | – | – | 6.55 | – | 9.53 | – | 12.7 | – | 15.88 | 6.55 | 9.53 | 18.05 |

| 150 | 6″ | 168.3 | 2.77 | 3.4 | – | – | – | 7.11 | – | 10.97 | – | 14.27 | – | 18.26 | 7.11 | 10.97 | 21.95 |

| 200 | 8″ | 219.1 | 2.77 | 3.76 | – | 6.35 | 7.04 | 8.18 | 10.31 | 12.7 | 15.09 | 18.26 | 20.62 | 23.01 | 8.18 | 12.7 | 22.23 |

| 250 | 10″ | 273.1 | 3.4 | 4.19 | – | 6.35 | 7.8 | 9.27 | 12.7 | 15.09 | 18.26 | 21.44 | 25.4 | 28.58 | 9.27 | 12.7 | 25.4 |

| 300 | 12″ | 323.9 | 3.96 | 4.57 | – | 6.35 | 8.38 | 10.31 | 14.27 | 17.48 | 21.44 | 25.4 | 28.58 | 33.32 | 9.53 | 12.7 | 25.4 |

| 350 | 14″ | 355.5 | 3.96 | 4.78 | 6.35 | 7.92 | 9.53 | 11.13 | 15.09 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | 9.53 | 12.7 | – |

| 400 | 16″ | 406.4 | 4.19 | 4.78 | 6.35 | 7.92 | 9.53 | 12.7 | 16.66 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | 9.53 | 12.7 | – |

| 450 | 18″ | 457.2 | 4.19 | 4.78 | 6.35 | 7.92 | 11.13 | 14.27 | 19.05 | 23.83 | 39.36 | 34.93 | 39.67 | 45.24 | – | – | – |

| 500 | 20″ | 508 | 4.78 | 5.54 | 6.35 | 9.53 | 12.7 | 15.09 | 20.62 | 26.19 | 32.54 | 38.1 | 44.45 | 50.01 | – | – | – |

| 550 | 22″ | 558.8 | 4.78 | 5.54 | 6.35 | 9.53 | 12.7 | – | 22.23 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | – | – | – |

| 600 | 24″ | 609.6 | 5.54 | 6.35 | 6.35 | 9.53 | 14.27 | 17.48 | 24.61 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | – | – | – |

The ASTM A53 Steel Pipe is a versatile carbon steel pipe, but it differs from other grades like ASTM A106, API 5L, and ASTM A500 in terms of application, composition, and performance. Below is a comparison to highlight its unique advantages for industrial piping and boiler pipeline protection:

The ASTM A53 Steel Pipe excels in versatility, balancing cost, strength, and corrosion resistance for applications like boiler pipeline protection and general piping, making it a go-to choice for engineers seeking reliable, budget-friendly solutions.

Hot-dipped galvanized coating protects against rust in harsh environments.

Durable carbon steel withstands wear from abrasive materials.

Suitable for boiler, structural, and general piping systems.

Supports welding and bending for flexible installation.

Long lifespan reduces maintenance and replacement costs.

Grade B offers superior tensile strength for demanding applications.

ASTM A53 Steel Pipe is commonly used in construction, energy, and transport industries for its strength, corrosion resistance, and structural versatility.

Used for transporting oil, gas, gasoline, and propane with optional anti-corrosion coatings in both onshore and offshore environments.

Widely used in columns, supports, bollards, sign poles, and piling due to its high load-bearing capacity and wide size range.

Hot-dip galvanized and lacquer-coated for use as electrical conduit in buildings, providing protection for electrical wiring systems.

Utilized in manufacturing conveyor rollers for transporting bulk materials like coal, ore, and sand in industrial systems.

Ideal for marine pipework exposed to saline environments, offering good corrosion resistance and mechanical durability.

Supports fluid transmission and pressure-bearing systems in water supply, HVAC, and industrial maintenance operations.

Astm a209 tubes offer seamless alloy steel solutio...

ASTM A192 seamless boiler tubes deliver exceptiona...

Astm a210 seamless boiler tubes offer excellent st...