Seamless Carbon Steel Boiler & Superheater Tubes

Astm a210 seamless boiler tubes offer excellent strength, dimensional accuracy, and temperature resistance. ideal for boilers, superheaters, and heat exchangers.

ASTM A210 Seamless Boiler Tubes are carbon steel pipes specifically manufactured for use in boiler tube protection, superheaters, and heat exchangers that operate under medium pressure. Engineered in accordance with ASTM A210/ASME SA210 standards, these seamless carbon steel tubes ensure high thermal conductivity, mechanical strength, and corrosion resistance—making them ideal for demanding industrial systems.

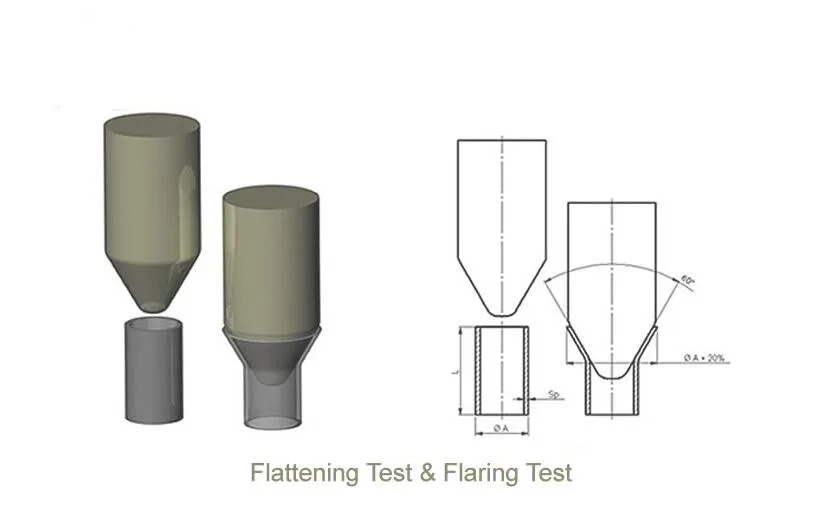

One flattening test shall be made on specimens from each end of one finished tube from each lot, but not the one used for the flaring test. Tears or breaks occur at the 12 or 6 o’clock positions on Grade C tubing with sizes of 2.375 in. [60.3 mm] in outside diameter and smaller shall not be considered a basis for rejection. One flaring test shall be made on species-men from each end of the one finished tube from each lot, but not the one used for the flattening test.

Produced through hot-rolling or cold-drawing, ASTM A210 tubes are designed to withstand continuous exposure to steam, pressure, and fluctuating temperatures. Their seamless construction eliminates weld seams, reducing the risk of leakage, failure, or weakness under stress. Cold-finished tubes are normalized or stress-relieved to ensure structural uniformity and durability.

The carbon steel tubing used in A210 offers a cost-effective solution for boiler maintenance and new installations, capable of handling high temperatures and internal pressure conditions. Applications include medium-pressure steam boilers, feedwater heaters, and shell-and-tube heat exchangers in power generation, petrochemical, oil refining, and industrial HVAC systems.

Available in outer diameters from 1/2" to 5", with wall thicknesses up to 12.7 mm, these medium pressure pipes are manufactured to precise tolerances for dimensional accuracy and installation efficiency. Ends can be beveled or plain, and surface treatments such as oiling or varnishing help prevent oxidation during storage and transport.

With superior boiler tube protection and enhanced heat transfer performance, ASTM A210 tubes meet critical requirements for mechanical integrity, thermal endurance, and cost-effectiveness in long-term industrial use.

| OD (mm) | Wall Thickness (mm) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | 6 | 6.5-7 | 7.5-8 | 8.5-9 | 9.5-10 | 11 | 12 | |

| Φ25-Φ28 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ32 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ34-Φ36 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ38 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ40 | ● | ● | ● | ● | ● | |||||||||

| Φ42 | ● | ● | ● | ● | ● | |||||||||

| Φ45 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ48-Φ60 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ63.5 | ● | ● | ● | ● | ● | ● | ● | |||||||

| Φ68-Φ73 | ● | ● | ● | ● | ● | ● | ||||||||

| Φ76 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ80 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ83 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ89 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ95 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ102 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ108 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||

| Φ114 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ121 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| Φ127 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

Tubes resist oxidation and corrosion in steam and flue gas environments, protecting boiler systems from long-term degradation.

Excellent heat transfer properties support efficient energy use in boiler and superheater systems.

Designed for easy fabrication and joining, suitable for bending, welding, and mechanical forming operations.

Low carbon content and high machinability reduce processing time and maintenance costs over long-term operation.

Withstands medium pressure and cyclic thermal loads in industrial heating systems and boilers.

Used across industries including oil refineries, thermal power plants, and petrochemical installations.

| Grade | C(Max) | Mn | Si(Min) | P(Max) | S(Max) |

|---|---|---|---|---|---|

| A1 | 0.27 | Max.0.93 | 0.10 | 0.035 | 0.035 |

| C | 0.35 | 0.29~1.06 | 0.10 | 0.035 | 0.035 |

| Grade | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation (%) |

|---|---|---|---|

| A1 | ≥ 415 | ≥ 255 | ≥ 30 |

| C | ≥ 485 | ≥ 275 | ≥ 30 |

| Feature | ASTM A210 Grade A1 | ASTM A192 | ASTM A179 |

|---|---|---|---|

| Material Type | Carbon Steel | Carbon Steel | Low Carbon Steel |

| Application | Medium Pressure Boilers, Superheaters | High Pressure Boilers, Superheaters | Heat Exchangers, Condensers |

| Manufacturing Process | Hot Rolled or Cold Drawn | Hot or Cold Finished | Cold Drawn |

| Tensile Strength (MPa) | ≥415 | ≥325 | ≥325 |

| Yield Strength (MPa) | ≥255 | ≥180 | ≥180 |

| Elongation (%) | ≥30 | ≥35 | ≥35 |

| Max Carbon Content (%) | 0.27 | 0.18 | 0.06 |

| Corrosion Resistance | Moderate (with coatings) | Good (High pressure service) | Moderate (Low temp environments) |

| Key Strength | Higher tensile & thicker wall capability | Optimized for high-pressure systems | Excellent thermal conductivity |

ASTM A210 tubes are widely used in industries requiring high-temperature, high-pressure, and durable tubing.

Crucial in boilers and superheaters for generating steam in power plants.

Used in heat exchangers, condensers, and high-temperature piping in refineries.

Employed in heat exchangers and processing equipment for sterility and stability.

Utilized in various industrial boilers for reliable heating and cooling performance.

Facilitates efficient heat transfer in various industrial processes.

Suitable for reliable fluid and gas transfer in high-temperature and pressure systems.

Astm a53 steel pipe meets stringent technical requ...

ASTM A192 seamless boiler tubes deliver exceptiona...

Astm a209 tubes offer seamless alloy steel solutio...