Seamless Carbon-molybdenum Alloy Steel Tubes For High-pressure Applications

Astm a209 tubes offer seamless alloy steel solutions for boilers and superheaters, ensuring high strength and corrosion resistance in high-pressure systems.

Seamless Carbon-molybdenum Alloy Steel Tubes For High-pressure Applications

Astm a209 tubes offer seamless alloy steel solutions for boilers and superheaters, ensuring high strength and corrosion resistance in high-pressure systems.

ASTM A209 Tubes are seamless carbon-molybdenum alloy steel tubes designed for high-pressure boiler and superheater applications, offering exceptional corrosion resistance and high-temperature strength. Conforming to ASTM A209/ASME SA209 standards, these tubes are ideal for boiler pipeline protection in power generation, petrochemical, and industrial heating systems. Available in Grades T1, T1a, and T1b, they provide superior durability and performance under extreme temperatures and pressures.

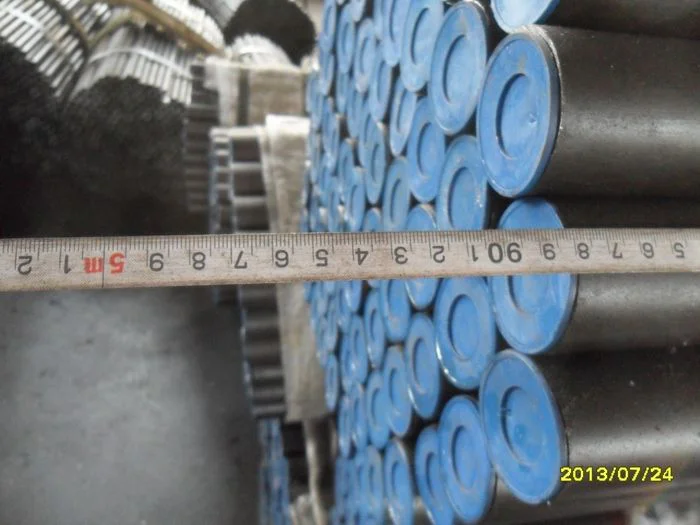

The ASTM A209 Tubes are manufactured through a seamless, hot-finished or cold-drawn process, followed by heat treatment to optimize mechanical properties and creep resistance. Available in outside diameters from 1/2” to 5” (12.7 mm to 127 mm) and wall thicknesses from 0.035” to 0.500” (0.9 mm to 12.7 mm), these tubes meet diverse project requirements. They undergo rigorous testing, including flattening, flaring, hardness, and hydrostatic tests, ensuring compliance with ASTM A209 standards. The carbon-molybdenum alloy composition (with molybdenum content of 0.44-0.65%) enhances abrasion resistance and high-temperature performance, making them suitable for seamless alloy steel tubes.

These seamless alloy steel tubes excel in high-pressure boiler systems and superheaters due to their ability to withstand thermal stress and corrosion. Their high tensile strength (min. 380 MPa for T1, 415 MPa for T1a, 365 MPa for T1b) and corrosion resistance make them ideal for environments exposed to high temperatures (up to 600°C) and corrosive fluids. Surface treatments like oil-dip, varnish, or passivation, along with options for straight or U-bent configurations, support versatile installation in industrial piping systems. The tubes are packed in wooden boxes or bundles with plastic paper for secure, sea-worthy delivery.

The ASTM A209 Tubes address critical challenges like pipeline wear, corrosion, and high-pressure stress in boiler systems. Their seamless design and alloyed composition make them a reliable choice for engineers seeking durable superheater tubes for extreme environments. Whether used in power plants or petrochemical facilities, these tubes deliver exceptional performance, safety, and longevity.

Withstands temperatures up to 600°C for boiler applications.

Molybdenum alloy enhances corrosion resistance in harsh conditions.

Durable alloy withstands pipeline wear and tear.

Seamless construction ensures reliability under high pressure.

Supports straight or U-bent configurations for flexibility.

High durability reduces maintenance and replacement costs.

| Element | Grade T1 (%) | Grade T1a (%) | Grade T1b (%) |

|---|---|---|---|

| Carbon (C) | 0.10-0.20 | 0.15-0.25 | 0.14 max |

| Manganese (Mn) | 0.30-0.80 | 0.30-0.80 | 0.30-0.80 |

| Phosphorus (P) | ≤0.025 | ≤0.025 | ≤0.025 |

| Sulfur (S) | ≤0.025 | ≤0.025 | ≤0.025 |

| Silicon (Si) | 0.10-0.50 | 0.10-0.50 | 0.10-0.50 |

| Molybdenum (Mo) | 0.44-0.65 | 0.44-0.65 | 0.44-0.65 |

| Property | Grade T1 | Grade T1a | Grade T1b |

|---|---|---|---|

| Tensile Strength, min (MPa) | 380 | 415 | 365 |

| Yield Strength, min (MPa) | 205 | 220 | 195 |

| Elongation, min (%) | 30 | 30 | 30 |

| Hardness, max (HRB) | 80 | 81 | 77 |

| Feature | ASTM A209 Grade T1 | ASTM A210 Grade A1 | ASTM A192 |

|---|---|---|---|

| Material Type | Carbon-Molybdenum Alloy Steel | Medium-Carbon Steel | Carbon Steel |

| Temperature Range | High (Up to 600°C) | High (Up to 600°C) | High (Up to 650°C) |

| Corrosion Resistance | Excellent (Molybdenum) | Moderate | Moderate |

| Applications | Boilers, Superheaters | Boilers, Superheaters | High-Pressure Boilers, Superheaters |

| Tensile Strength (MPa) | 380 (min) | 415 (min) | 325 (min) |

| Yield Strength (MPa) | 205 (min) | 255 (min) | 180 (min) |

| Key Advantage | Enhanced creep resistance | High strength for boilers | High-pressure resistance |

ASTM A209 Tubes are widely utilized in industries requiring high-temperature resistance, creep resistance, and robust corrosion protection for boiler and superheater systems.

Used in superheaters for efficient steam generation in power plants, enhancing energy efficiency with boiler pipeline protection.

Employed in high-temperature processes like catalytic cracking, offering corrosion resistance in refineries.

Utilized for seamless heat transfer in high-temperature fluid systems, ensuring abrasion resistance.

Critical for heat transfer in boiler systems, providing high-pressure tubes with creep resistance.

Used in exhaust systems across automotive and aerospace, ensuring seamless alloy steel tubes durability.

Applied in furnace components for high-temperature operations, offering corrosion resistance and longevity.

Astm a53 steel pipe meets stringent technical requ...

ASTM A192 seamless boiler tubes deliver exceptiona...

Astm a210 seamless boiler tubes offer excellent st...