DIN EN Steel Pipes are seamless and welded steel tubes adhering to standards like DIN EN 10216, DIN EN 10208, and DIN EN 10305, designed for high-pressure, high-temperature, and precision applications. These pipes offer exceptional corrosion resistance and durability, making them ideal for high-pressure piping in oil and gas, power generation, and automotive industries. Grades like P235GH, S235J2, and St52.0 ensure versatility across demanding environments.

Manufactured through seamless cold-drawn, hot-rolled, or welded processes, DIN EN Steel Pipes undergo heat treatment (e.g., normalizing or annealing) to optimize mechanical properties. Available in diameters from 4 mm to 610 mm and wall thicknesses from 0.5 mm to 60 mm, they meet diverse project needs. Rigorous testing, including ultrasonic, eddy current, and hydrostatic tests, ensures compliance with DIN EN standards. The carbon and alloy steel compositions enhance abrasion resistance, making them suitable for seamless steel tubes in extreme conditions.

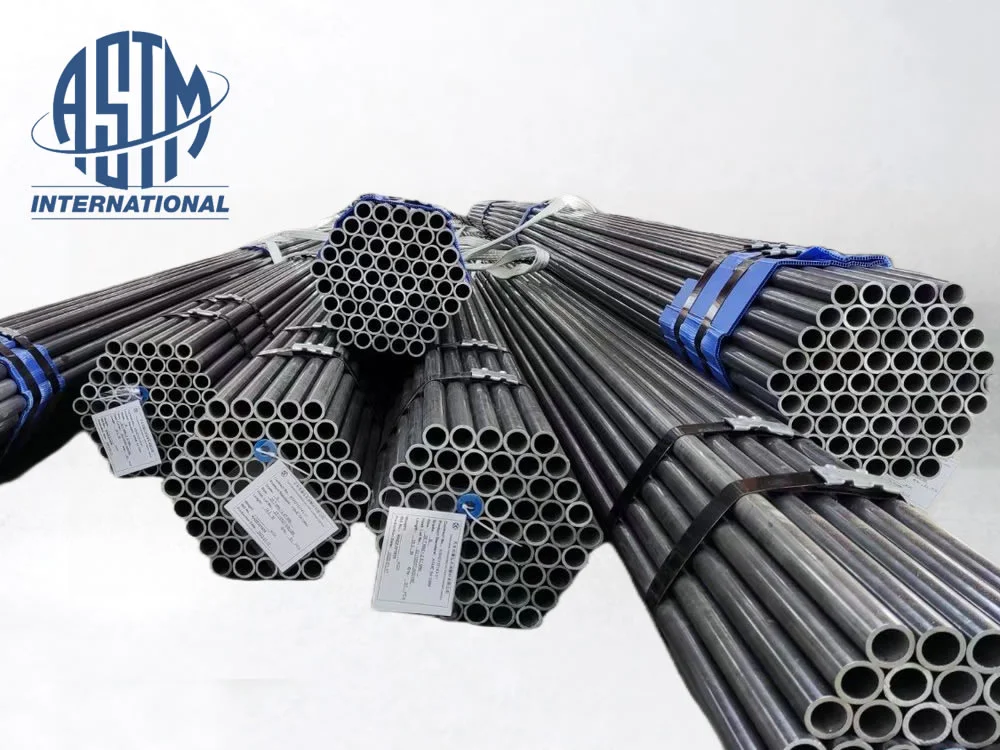

These seamless steel tubes excel in high-pressure and precision systems due to their high tensile strength (e.g., min. 360 MPa for P235GH) and excellent corrosion resistance. Surface treatments like galvanization, varnish, or coating, and end configurations like plain, beveled, or threaded, support versatile installation in pipeline systems. Packaged in bundles or wooden boxes, they ensure secure delivery. DIN EN steel pipes are a reliable choice for engineers seeking durable precision steel tubes for critical applications.

Addressing challenges like high-pressure stress, corrosion, and dimensional precision, DIN EN Steel Pipes deliver exceptional performance, safety, and longevity. Their robust design and standardized specifications make them ideal for industrial applications requiring reliability and interchangeability.