High‑temperature Boilers & Pressure Systems

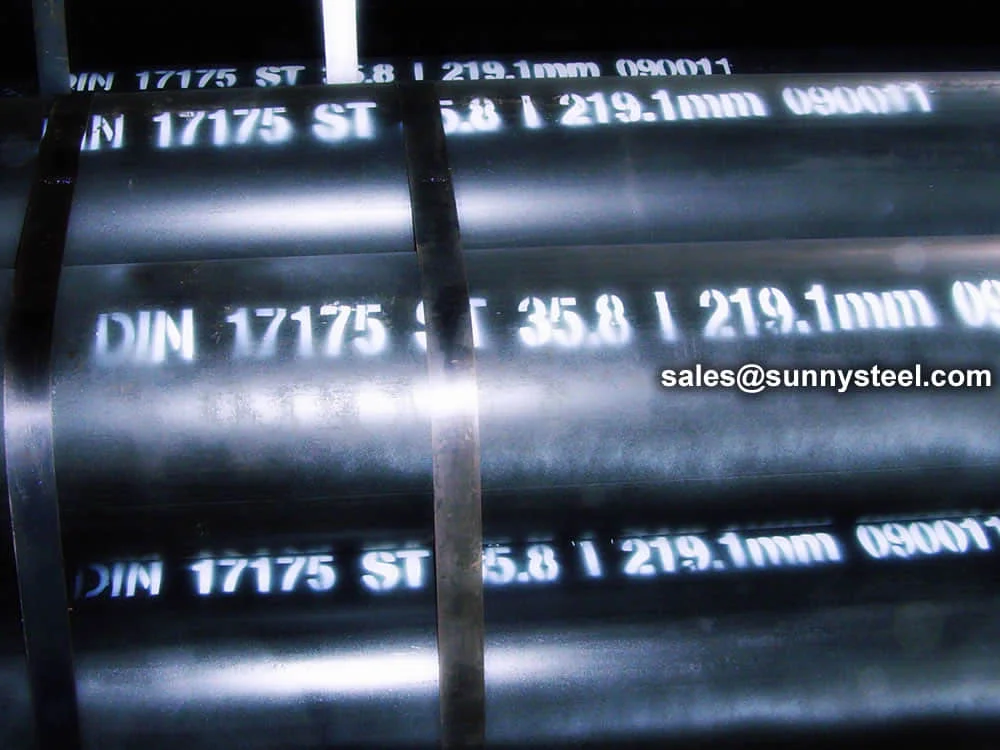

Din 17175 seamless steel tubes in grades st35.

High‑temperature Boilers & Pressure Systems

Din 17175 seamless steel tubes in grades st35.8, st45.8, 15mo3, 13crmo44, and 10crmo910 offer superior mechanical strength and heat resistance for boilers, heat exchangers, and high-pressure systems up to 600 °c.

DIN 17175 Steel Tubes are seamless non-alloy and alloy steel tubes designed for high-temperature applications, such as boiler installations, high-pressure pipelines, and pressure vessel construction. Conforming to the DIN 17175 standard, these tubes are suitable for temperatures up to 600°C, offering excellent corrosion resistance and high-temperature strength in industries like power generation, petrochemical, and chemical processing.

Manufactured through seamless hot-rolled or cold-drawn processes, DIN 17175 Steel Tubes undergo heat treatments like normalizing or annealing to enhance creep resistance and mechanical properties. Available in grades St35.8, St45.8, 15Mo3, 13CrMo44, and 10CrMo910, they range in outer diameters from 10 mm to 610 mm and wall thicknesses from 1 mm to 60 mm. Rigorous testing, including hydrostatic, ultrasonic, and non-destructive tests, ensures compliance with DIN 17175 standards. The alloyed compositions, with elements like molybdenum and chromium, enhance abrasion resistance, making them ideal for seamless alloy steel tubes.

These high-temperature piping solutions support welding methods like arc and gas fusion, with surface treatments such as galvanization or anti-corrosion coatings and end configurations like plain or beveled. Packaged in bundles or wooden crates, they ensure secure delivery. DIN 17175 tubes address challenges like thermal stress and corrosion, making them a reliable choice for boiler tubes and pressure vessel tubes.

Withstands temperatures up to 600°C for boiler and pipeline applications.

Alloyed composition ensures durability in corrosive environments.

Durable materials withstand wear in high-pressure systems.

Seamless design ensures reliability under high temperatures.

Supports various welding and end configurations.

High durability reduces maintenance costs.

DIN 17175 specifies seamless steel tubes for elevated temperatures, used in boiler installations, high-pressure pipelines, and pressure vessel construction. Suitable for temperatures up to 600°C, these tubes are designed for high-temperature piping in power generation, petrochemical, and chemical industries, offering excellent creep resistance and durability.

DIN 17175 defines non-alloy and alloy steel grades, including:

DIN 17175 Steel Tubes are available in a range of sizes and tolerances:

| Element | St35.8 (%) | 15Mo3 (%) | 13CrMo44 (%) |

|---|---|---|---|

| Carbon (C) | ≤0.17 | 0.12-0.20 | 0.10-0.18 |

| Manganese (Mn) | 0.40-0.80 | 0.40-0.80 | 0.40-0.70 |

| Phosphorus (P) | ≤0.040 | ≤0.035 | ≤0.035 |

| Sulfur (S) | ≤0.040 | ≤0.035 | ≤0.035 |

| Silicon (Si) | ≤0.35 | 0.10-0.35 | 0.10-0.35 |

| Molybdenum (Mo) | - | 0.25-0.35 | 0.45-0.65 |

| Chromium (Cr) | - | - | 0.70-1.15 |

| Property | St35.8 | 15Mo3 | 13CrMo44 |

|---|---|---|---|

| Tensile Strength, min (MPa) | 360-480 | 450-600 | 440-590 |

| Yield Strength, min (MPa) | 235 | 270 | 290 |

| Elongation, min (%) | 25 | 22 | 22 |

| Hardness, max (HRB) | 89 | 91 | 92 |

| Feature | DIN 17175 St35.8 | EN 10216-2 P235GH | ASTM A192 |

|---|---|---|---|

| Material Type | Non-Alloy Steel | Non-Alloy Steel | Carbon Steel |

| Temperature Range | Up to 600°C | Up to 450°C | Up to 650°C |

| Corrosion Resistance | Moderate | Moderate | Moderate |

| Applications | Boilers, Pipelines | Boilers, Pipelines | Boilers, Superheaters |

| Tensile Strength (MPa) | 360-480 | 360-500 | 325-455 |

| Yield Strength (MPa) | 235 | 235 | 180 |

| Key Advantage | High-temperature durability | Pressure equipment | High-pressure boilers |

A curated list of long-tail keywords for DIN 17175 seamless steel tubes, covering specifications, applications, and material properties, presented in a two-column layout.

Note: DIN 17175 covers seamless non-alloy and alloy steel tubes for high-temperature applications. For detailed specifications, refer to the DIN 17175 standard or contact a certified supplier.

DIN 17175 Seamless Steel Tubes are widely used in industries requiring high-temperature and high-pressure resistance for seamless applications.

Used in high-temperature boiler tubes, ensuring high-temperature piping reliability.

Employed in superheaters and heat exchangers, offering seamless alloy steel tubes.

Applied in high-pressure pipelines, leveraging corrosion resistance.

Used for corrosive fluids, benefiting from abrasion resistance.

Employed in vessel construction, offering seamless steel tubes.

Used in high-temperature piping, ensuring structural integrity.

Din 1629 seamless carbon steel pipes (st37, st44, ...

En 10208 carbon steel pipes meet european standard...

Din 2391 seamless precision steel tubes offer high...