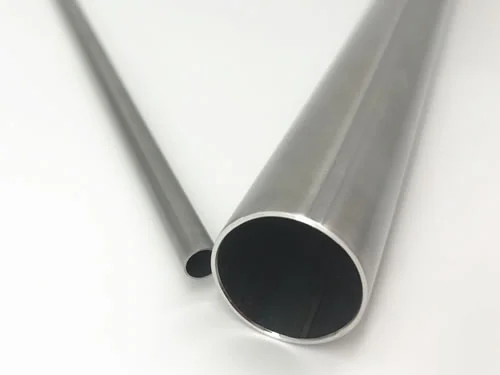

High-precision Tubes For Hydraulic And Automotive Applications

Din 2391 seamless precision steel tubes offer high precision, corrosion resistance, and durability for hydraulic and automotive applications.

High-precision Tubes For Hydraulic And Automotive Applications

Din 2391 seamless precision steel tubes offer high precision, corrosion resistance, and durability for hydraulic and automotive applications.

DIN 2391 Seamless Precision Steel Tubes are engineered for high-precision applications, offering exceptional corrosion resistance and durability. Conforming to DIN 2391-1 and DIN 2391-2 standards, these cold-drawn or cold-rolled tubes are ideal for hydraulic steel tubes, automotive piping, and industrial piping systems. Their seamless construction ensures tight dimensional tolerances and smooth surfaces, making them perfect for demanding environments like hydraulic systems, automotive components, and machinery.

Manufactured through advanced cold-drawing or cold-rolling processes, DIN 2391 Tubes achieve superior mechanical properties and surface quality. Available in grades such as St35, St45, and St52, these tubes are designed for applications requiring high precision and corrosion resistance. The tubes undergo heat treatments like NBK (normalized, bright annealed) or GBK (annealed) to enhance strength and flexibility. With outer diameters ranging from 4mm to 350mm and wall thicknesses from 0.5mm to 50mm, they meet diverse project needs, from boiler pipeline protection to precision engineering.

Seamless Precision Steel Tubes are subjected to rigorous testing, including eddy current, tensile, and hydrostatic tests, ensuring compliance with DIN 2391 standards. Their high tensile strength (up to 580 MPa for St52) and yield strength (minimum 420 MPa for St52) make them suitable for high-pressure systems. The smooth inner surface reduces friction, enhancing fluid flow efficiency in hydraulic steel tubes. Surface treatments like phosphating or galvanizing further improve corrosion resistance, making these tubes ideal for harsh environments in automotive and industrial applications.

Compared to standard seamless pipes, DIN 2391 Seamless Precision Steel Tubes offer superior dimensional accuracy and surface finish, reducing machining time and costs. Their ability to withstand high-pressure and corrosive conditions makes them a preferred choice for automotive piping applications like fuel injection systems and shock absorbers. The tubes’ versatility also extends to manufacturing precision components like fittings and couplings, ensuring compatibility with complex industrial piping systems.

DIN 2391 Tubes address critical challenges like pipeline wear, corrosion, and dimensional inaccuracies in high-performance systems. Their advanced manufacturing and robust material properties make them a reliable choice for engineers seeking durable seamless precision steel tubes for extreme environments. Whether used in hydraulic systems, automotive components, or industrial machinery, these tubes deliver unmatched performance, safety, and longevity.

Phosphated or galvanized coatings protect against rust in harsh environments.

Tight tolerances ensure seamless fit in hydraulic and automotive systems.

Ideal for hydraulic, automotive, and industrial piping systems.

Supports bending and flanging for complex piping designs.

Reduced machining time lowers overall project costs.

Superior tensile strength for high-pressure applications.

| Standard | Grade | Chemical Components (%) | |||||

|---|---|---|---|---|---|---|---|

| Symbol | Material No. | C | Si | Mn | P (max) | S (max) | |

| DIN 2391 | St 30 Si | 1.0211 | ≤0.10 | ≤0.10 | ≤0.55 | ≤0.025 | ≤0.025 |

| St 30 Al | 1.0212 | ≤0.10 | ≤0.05 | ≤0.55 | ≤0.025 | ≤0.025 | |

| St 35 | 1.0308 | ≤0.17 | ≤0.35 | ≥0.40 | ≤0.025 | ≤0.025 | |

| St 45 | 1.0408 | ≤0.21 | ≤0.35 | ≥0.40 | ≤0.025 | ≤0.025 | |

| St 52 | 1.0570 | ≤0.22 | ≤0.55 | ≤1.60 | ≤0.025 | ≤0.025 | |

| Steel Name | Steel Number | Minimum Values for Delivery Condition | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BK | BKW | BKS | GBK | NBK | |||||||||

| Rm (MPa) |

A (%) |

Rm (MPa) |

A (%) |

Rm (MPa) |

ReH (MPa) |

A (%) |

Rm (MPa) |

A (%) |

Rm (MPa) |

ReH (MPa) |

A (%) |

||

| St 30 Si | 1.0211 | 430 | 8 | 380 | 12 | 380 | 280 | 16 | 280 | 30 | 290-420 | 215 | 30 |

| St 30 Al | 1.0212 | 430 | 8 | 380 | 12 | 380 | 280 | 16 | 280 | 30 | 290-420 | 215 | 30 |

| St 35 | 1.0308 | 480 | 6 | 420 | 10 | 420 | 315 | 14 | 315 | 25 | 340-470 | 235 | 25 |

| St 45 | 1.0408 | 580 | 5 | 520 | 8 | 520 | 375 | 12 | 390 | 21 | 440-570 | 255 | 21 |

| St 52 | 1.0580 | 640 | 4 | 580 | 7 | 580 | 420 | 10 | 490 | 22 | 490-630 | 355 | 22 |

| Feature | DIN 2391 Tubes | ASTM A106 Grade B | EN 10305-1 Tubes |

|---|---|---|---|

| Material Type | Carbon Steel | Carbon Steel | Carbon Steel |

| Temperature Range | Ambient to moderate | High (up to 427°C) | Ambient to moderate |

| Precision | High (Tight tolerances) | Moderate | High (Similar to DIN 2391) |

| Corrosion Resistance | Good (With coatings) | Moderate | Good (With coatings) |

| Applications | Hydraulic, Automotive, Industrial | Boilers, Refineries | Hydraulic, Mechanical |

| Tensile Strength (MPa) | 580 (St52) | 415 (min) | 580 (E355) |

| Yield Strength (MPa) | 420 (St52) | 240 (min) | 450 (E355) |

| Key Advantage | High precision and surface quality | General high-temp use | High precision for mechanical use |

| Designation | Symbol | Description |

|---|---|---|

| Cold finished (hard) | BK | Tubes do not undergo heat treatment following the final cold forming and thus, have a rather high resistance to deformation. |

| Cold finished (soft) | BKW | The final heat treatment is followed by cold drawing involving limited deformation. Appropriate further processing allows a certain degree of cold forming (e.g. bending, expanding). |

| Cold finished and stress-relieved | BKS | Heat treatment is applied following the last cold forming process. Subject to appropriate processing conditions, the increase in the residual stresses involved enables both forming and machining to a certain degree. |

| Annealed | GBK | The last cold forming process is followed by annealing in a controlled atmosphere. |

| Normalized | NBK | The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere. |

| Symbol in accordance with EN 10305 | Symbol in accordance with DIN 2391 | Processing Description |

|---|---|---|

| +C | BK | Cold finished (hard) |

| +LC | BKW | Cold finished (soft) |

| +SR | BKS | Cold finished and stress-relieved |

| +A | GBK | Annealed |

| +N | NBK | Normalized |

| Inspection or Test Types | Test Frequency | |

|---|---|---|

| Internal Test | Acceptance Test | |

| Chemical analysis | M | M |

| Tensile testing | M | One per tested batch |

| Flattening test or extension test | M | Two per tested batch |

| Dimension verification | M | M |

| Visual inspection | M | M |

| NDT in order to identify leaks | Individual | Individual |

A curated list of long-tail keywords for DIN 2391 seamless precision steel tubes, covering specifications, applications, and material properties, presented in a multi-column layout.

Note: DIN 2391 covers seamless precision steel tubes for hydraulic and automotive applications. For detailed specifications, refer to the DIN 2391 standard or contact a certified supplier.

DIN 2391 Seamless Precision Steel Tubes are widely used in industries requiring high precision, corrosion resistance, and durability in demanding applications.

Used in high-pressure hydraulic and pneumatic systems for fluid power transmission.

Ideal for fuel injection systems, shock absorbers, and steering components.

Used in precision machinery for manufacturing and processing equipment.

Ensures reliable performance in air-powered systems for automation and control.

Handles control lines and instrumentation tubing in exploration and refining.

Used in manufacturing precision components like fittings and couplings.

Din 1629 seamless carbon steel pipes (st37, st44, ...

En 10208 carbon steel pipes meet european standard...

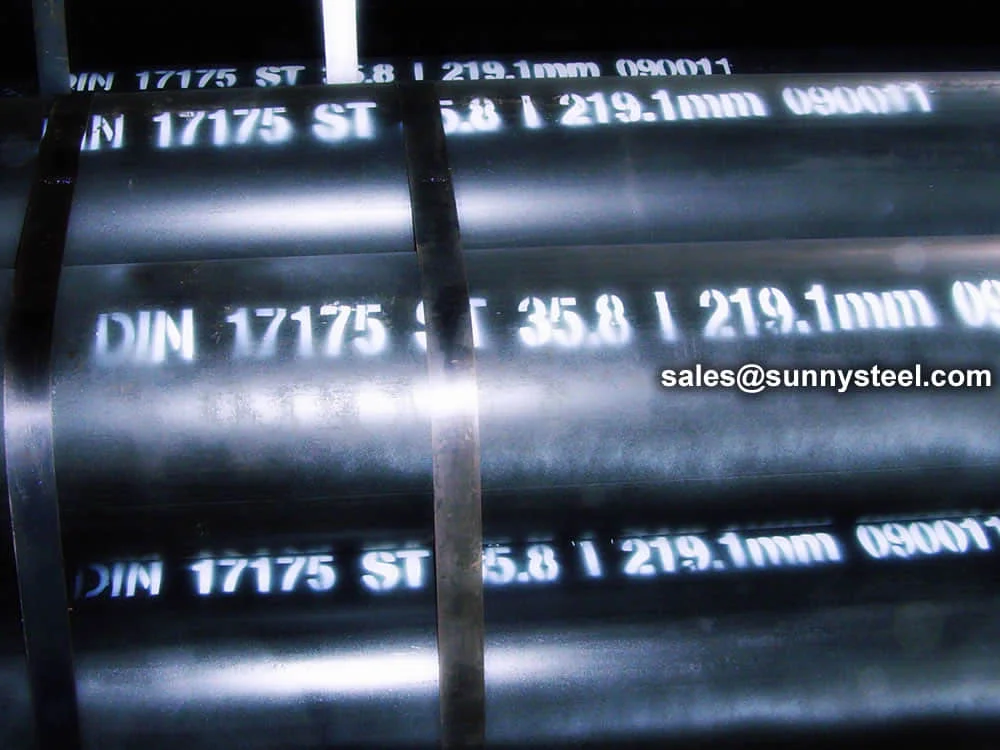

Din 17175 seamless steel tubes in grades st35.8, s...