Tubo Soldado Em St37.2, Com Acabamento Preto Ou Galvanizado, Ideal Para Sistemas De Condução, Estruturas E Caldeiras.

Tubo preto din 2458 oferece resistência mecânica, conformidade com padrões europeus e versatilidade de uso em caldeiras, estruturas metálicas e condução de fluidos.

Tubo Soldado Em St37.2, Com Acabamento Preto Ou Galvanizado, Ideal Para Sistemas De Condução, Estruturas E Caldeiras.

Tubo preto din 2458 oferece resistência mecânica, conformidade com padrões europeus e versatilidade de uso em caldeiras, estruturas metálicas e condução de fluidos.

DIN 2458 Tubo Preto refers to welded carbon steel pipes manufactured to the DIN 2458 standard, renowned for their strength and durability. These black steel pipes are ideal for construction piping, water transport pipes, and industrial piping systems, including applications in evaporators, heaters, and gas conduits. The standard outlines dimensions and masses, ensuring compliance with technical delivery conditions as per related standards like DIN 1628.

DIN 2458 Tubo Preto is produced with a longitudinal weld, typically using carbon steel grades like St37.2, which provides robust mechanical properties. Available in black or galvanized finishes, these pipes come with plain, beveled, or threaded ends (BSP or NPT), making them versatile for structural and low-pressure fluid conduction applications (up to 150 lbs). They are available in outer diameters from 12.7 mm to 127 mm, wall thicknesses from 0.9 mm to 9.1 mm, and standard lengths of 6 meters.

These carbon steel welded pipes undergo stringent testing, including hydrostatic tests at 40 kg/cm² (570 PSI), to ensure reliability in demanding environments. Optional heat treatments, such as normalization at 920°C, enhance their suitability for applications like thermal exchange systems. Surface treatments like galvanizing improve corrosion resistance, making them suitable for harsh conditions in construction and industrial settings.

Compared to seamless pipes like DIN 2391, DIN 2458 Tubo Preto offers a cost-effective solution for applications where high precision is not critical. Their welded construction and ability to undergo cold working processes like flanging and bending make them ideal for construction piping and water transport pipes. Widely used in Brazil and globally, they align with equivalent standards like NBR 5595 for thermal exchange applications.

DIN 2458 Tubo Preto addresses challenges such as structural stability and efficient fluid transport in low-pressure systems. Their robust design and compliance with rigorous standards make them a trusted choice for engineers and contractors in construction, industrial machinery, and water distribution projects, ensuring performance and longevity.

Robust carbon steel construction ensures long-term reliability.

Welded design offers affordable solutions for low-pressure systems.

Suitable for construction, water transport, and industrial piping.

Supports flanging, bending, and cold working for diverse designs.

Galvanized options enhance resistance to rust in harsh environments.

Hydrostatic testing ensures performance under pressure.

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤0.17 |

| Manganese (Mn) | ≤1.40 |

| Phosphorus (P) | ≤0.045 |

| Sulfur (S) | ≤0.045 |

| Silicon (Si) | ≤0.55 |

| Property | Value |

|---|---|

| Tensile Strength, min (MPa) | 340–470 |

| Yield Strength, min (MPa) | 235 |

| Elongation, min (%) | 20 |

| Feature | DIN 2391 Tubes | ASTM A106 Grade B | EN 10305-1 Tubes |

|---|---|---|---|

| Material Type | Carbon Steel | Carbon Steel | Carbon Steel |

| Temperature Range | Ambient to moderate | High (up to 427°C) | Ambient to moderate |

| Precision | High (Tight tolerances) | Moderate | High (Similar to DIN 2391) |

| Corrosion Resistance | Good (With coatings) | Moderate | Good (With coatings) |

| Applications | Hydraulic, Automotive, Industrial | Boilers, Refineries | Hydraulic, Mechanical |

| Tensile Strength (MPa) | 580 (St52) | 415 (min) | 580 (E355) |

| Yield Strength (MPa) | 420 (St52) | 240 (min) | 450 (E355) |

| Key Advantage | High precision and surface quality | General high-temp use | High precision for mechanical use |

| Designation | Symbol | Description |

|---|---|---|

| Cold finished (hard) | BK | Tubes do not undergo heat treatment following the final cold forming and thus, have a rather high resistance to deformation. |

| Cold finished (soft) | BKW | The final heat treatment is followed by cold drawing involving limited deformation. Appropriate further processing allows a certain degree of cold forming (e.g. bending, expanding). |

| Cold finished and stress-relieved | BKS | Heat treatment is applied following the last cold forming process. Subject to appropriate processing conditions, the increase in the residual stresses involved enables both forming and machining to a certain degree. |

| Annealed | GBK | The last cold forming process is followed by annealing in a controlled atmosphere. |

| Normalized | NBK | The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere. |

| Symbol in accordance with EN 10305 | Symbol in accordance with DIN 2391 | Processing Description |

|---|---|---|

| +C | BK | Cold finished (hard) |

| +LC | BKW | Cold finished (soft) |

| +SR | BKS | Cold finished and stress-relieved |

| +A | GBK | Annealed |

| +N | NBK | Normalized |

| Inspection or Test Types | Test Frequency | |

|---|---|---|

| Internal Test | Acceptance Test | |

| Chemical analysis | M | M |

| Tensile testing | M | One per tested batch |

| Flattening test or extension test | M | Two per tested batch |

| Dimension verification | M | M |

| Visual inspection | M | M |

| NDT in order to identify leaks | Individual | Individual |

A curated list of long-tail keywords for DIN 2458 Tubo Preto, covering specifications, applications, and material properties, presented in a multi-column layout.

Note: DIN 2458 covers welded carbon steel pipes for structural and low-pressure fluid applications. For detailed specifications, refer to the DIN 2458 standard or contact a certified supplier.

DIN 2458 Tubo Preto is widely used in industries requiring strength, durability, and cost-effective solutions for structural and low-pressure fluid transport applications.

Used in structural frameworks, scaffolding, and building supports for robust construction projects.

Ideal for water distribution networks and irrigation systems with low-pressure requirements.

Used in low-pressure gas and air conduits for industrial machinery and systems.

Applied in evaporators, heaters, and superheaters for efficient heat transfer.

Utilized in irrigation systems and structural components for farming machinery.

Supports fluid transport and structural roles in industrial mechanical setups.

Din 1629 seamless carbon steel pipes (st37, st44, ...

En 10208 carbon steel pipes meet european standard...

Din 2391 seamless precision steel tubes offer high...

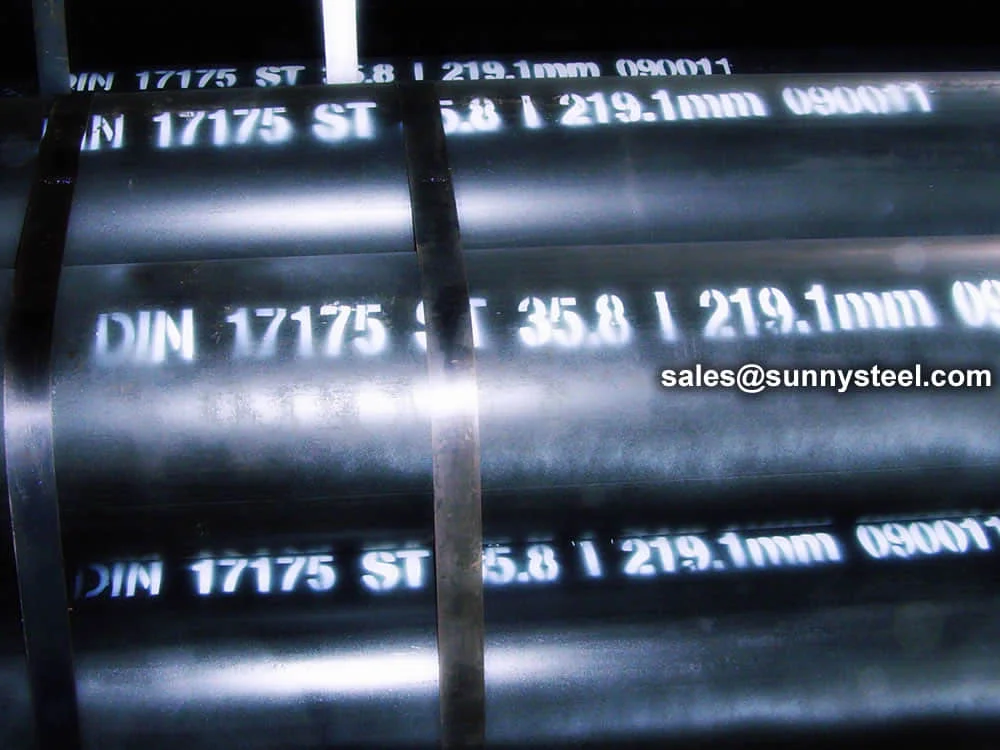

Din 17175 seamless steel tubes in grades st35.8, s...