Seamless And Welded Carbon Steel Pipeline Tubes, Designed To En 10208-1/-2 Standards For Safe Combustible Fluid Transport.

En 10208 carbon steel pipes meet european standards for transporting gas, oil, and combustible fluids, offering precise tolerances, certified materials, and robust quality for mining, chemical, and power industries.

Seamless And Welded Carbon Steel Pipeline Tubes, Designed To En 10208-1/-2 Standards For Safe Combustible Fluid Transport.

En 10208 carbon steel pipes meet european standards for transporting gas, oil, and combustible fluids, offering precise tolerances, certified materials, and robust quality for mining, chemical, and power industries.

EN 10208 carbon steel pipes are engineered for pipelines transporting combustible fluids, such as gas, oil, and other flammable substances, in industries like mining, chemical, and power engineering. These pipes comply with the European standard BS EN 10208, which specifies technical delivery conditions for seamless and welded steel pipes used primarily in gas supply systems, excluding petroleum and natural gas industry pipelines covered by ISO 3183.

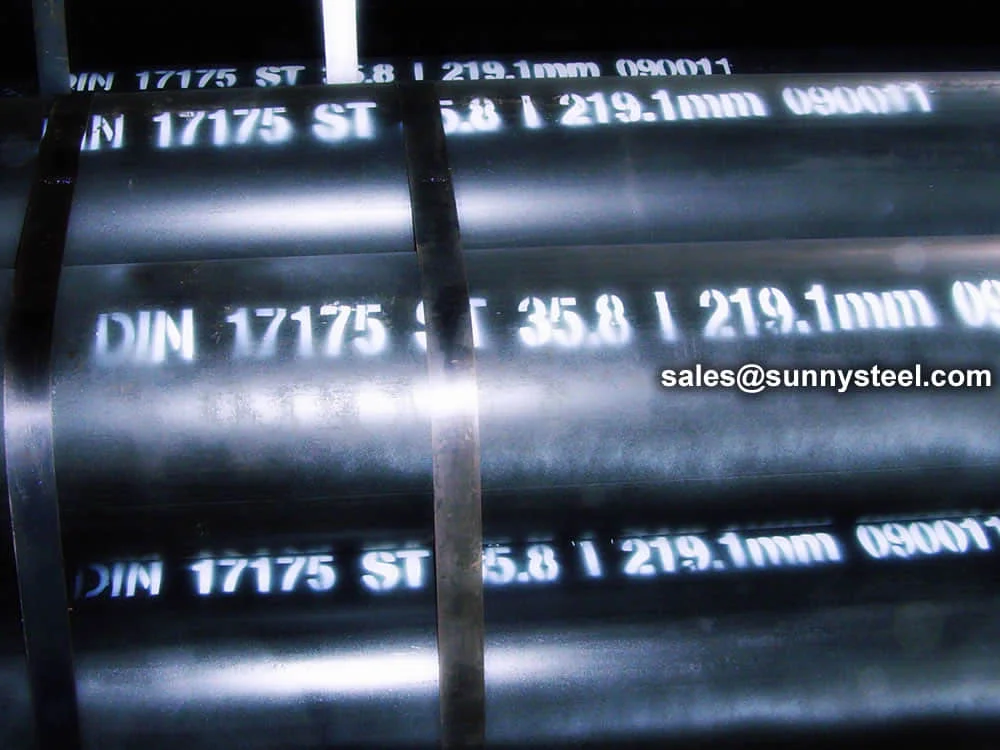

Available in both seamless and welded forms, EN 10208 pipes are manufactured with outer diameters ranging from 10.2 mm to 660 mm. Seamless pipes have wall thicknesses up to 40 mm (hot-rolled) or 10 mm (cold-drawn), while welded pipes, including LSAW (Longitudinal Submerged Arc Welded) and SSAW (Spiral Submerged Arc Welded), support larger diameters. These pipes are designed to withstand specific pressures, making them ideal for gas pipeline steel and oil transport pipes in demanding environments.

The standard is divided into two requirement classes: Class A (EN 10208-1) for standard quality and Class B (EN 10208-2) for enhanced toughness and non-destructive testing, suitable for transmission pipelines. Common steel grades include L210GA, L235GA, L290GA, and L360GA, with yield strengths from 210 MPa to 360 MPa. The pipes undergo rigorous testing, such as hydrostatic, Charpy impact, and weld seam inspections, to ensure reliability and prevent issues like shear fracture in gas pipelines.

EN 10208 carbon steel pipes offer excellent mechanical properties, with options for coatings like polyethylene or epoxy for enhanced corrosion resistance. They are versatile for applications in gas supply systems, chemical processing, and power plants, providing cost-effective and durable solutions for fluid transport under pressure. Compared to standards like ASTM A53 or DIN 2458, EN 10208 emphasizes specific requirements for combustible fluid pipelines, ensuring safety and performance.

These pipes address challenges like high-pressure fluid transport and environmental durability, making them a preferred choice for engineers and project managers in infrastructure projects requiring welded carbon steel pipes for combustible fluids. Their compliance with stringent standards ensures long-term performance in critical applications.

EN 10208 pipes are seamless and welded carbon steel tubes designed per European standards (Parts 1–3) for combustible fluid transport in mining, chemical processing, power, and gas distribution systems.

Designed to withstand specific pressures for combustible fluid transport.

Welded options provide affordable solutions for large-scale pipelines.

Suitable for gas, oil, and chemical fluid transport systems.

Coatings like polyethylene enhance durability in harsh environments.

Hydrostatic and Charpy impact tests ensure pipeline safety.

Available in seamless and welded forms for diverse project needs.

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤0.17 |

| Manganese (Mn) | ≤0.80 |

| Phosphorus (P) | ≤0.040 |

| Sulfur (S) | ≤0.035 |

| Silicon (Si) | ≤0.40 |

| Property | Value |

|---|---|

| Yield Strength, min (MPa) | 290 |

| Tensile Strength, min (MPa) | 415–555 |

| Elongation, min (%) | 21 |

| Feature | EN 10208 (L290GA) | ASTM A53 Grade B | DIN 2458 (St37.2) |

|---|---|---|---|

| Material Type | Carbon Steel (Seamless/Welded) | Carbon Steel (Seamless/Welded) | Carbon Steel (Welded) |

| Temperature Range | Ambient to moderate | Low to moderate | Low to moderate |

| Precision | Moderate | Moderate | Moderate |

| Corrosion Resistance | Good (With coatings) | Good (With galvanization) | Good (With galvanization) |

| Applications | Gas/Oil Pipelines, Chemical | Structural, Low-Pressure Systems | Construction, Water Transport |

| Tensile Strength (MPa) | 415–555 | 415–550 | 340–470 |

| Yield Strength (MPa) | 290 | 240 | 235 |

| Key Advantage | Optimized for combustible fluids | Versatile for general use | Cost-effective for structural use |

| Steel Designation | Maximum Content, % | CEV max. |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | V | Nb | Ti | Other | ||

| Steels for seamless and welded pipes | ||||||||||

|

L245NB L290NB L360NB L415NB |

0.16 0.17 0.20 0.21 |

0.40 0.40 0.45 0.45 |

1.1 1.2 1.6 1.6 |

0.025 0.025 0.025 0.025 |

- 0.05 0.10 0.15 |

- 0.05 0.10 0.15 |

- 0.05 0.05 0.05 |

- 0.04 0.04 0.04 |

- |

0.42 0.42 0.42 0.45 to be negotiated |

| Steels for seamless pipes | ||||||||||

|

L360QB L415QB L450QB L485QB L555QB |

0.16 0.16 0.16 0.16 0.16 |

0.45 0.45 0.45 0.45 0.45 |

1.4 1.6 1.6 1.7 1.8 |

0.025 0.025 0.025 0.025 0.025 |

0.020 0.020 0.020 0.020 0.020 |

0.05 0.08 0.09 0.10 0.10 |

0.05 0.05 0.05 0.05 0.06 |

0.04 0.04 0.06 0.06 0.06 |

- |

0.42 0.43 0.45 0.45 to be negotiated |

| Steels for welded pipes | ||||||||||

|

L245MB L290MB L360MB L415MB L450MB L485MB L555MB |

0.16 0.16 0.16 0.16 0.16 0.16 0.16 |

0.45 0.45 0.45 0.45 0.45 0.45 0.45 |

1.5 1.5 1.6 1.6 1.6 1.7 1.8 |

0.025 0.025 0.025 0.025 0.025 0.025 0.025 |

0.020 0.020 0.020 0.020 0.020 0.020 0.020 |

0.04 0.04 0.05 0.08 0.10 0.10 0.10 |

0.04 0.04 0.05 0.05 0.05 0.06 0.06 |

- - 0.04 0.06 0.06 0.06 0.06 |

- |

0.40 0.40 0.41 0.42 0.43 0.43 to be negotiated |

| Steel Designation | Pipe Body (Seamless & Welded Pipe) | Spiral Weld | Whole Pipe | ||||

|---|---|---|---|---|---|---|---|

| Plastic Limit R10.5 (N/mm²) |

Tensile Strength Rm (N/mm² min.) |

R10.5/Rm (Max) | Elongation A (%) min. |

HFW, SAW, COW Tensile Strength Rm (N/mm² min.) |

SAW, COW Bending Mandrel Diameter |

||

|

L245NB L245MB |

245 to 440 | 415 |

0.80 0.85 |

22 | Same as pipe body | 3T | Every pipe must pass pressure test with no leaks or deformations |

|

L290NB L290MB |

290 to 440 | 415 |

0.85 0.85 |

21 | 3T | ||

|

L360NB L360QB L360MB |

360 to 510 | 460 |

0.85 0.88 0.85 |

20 | 4T | ||

|

L415NB L415QB L415MB |

415 to 565 | 520 |

0.85 0.88 0.85 |

18 | 5T | ||

|

L450QB L450MB |

450 to 570 | 535 |

0.90 0.87 |

18 | 6T | ||

|

L485QB L485MB |

485 to 605 | 570 |

0.90 0.90 |

18 | 6T | ||

|

L555QB L555MB |

555 to 675 | 625 |

0.90 0.90 |

18 | 6T | ||

| Inspection or Test Types | Test Frequency | |

|---|---|---|

| Internal Test | Acceptance Test | |

| Chemical analysis | M | M |

| Tensile testing | M | One per tested batch |

| Flattening test or extension test | M | Two per tested batch |

| Dimension verification | M | M |

| Visual inspection | M | M |

| NDT in order to identify leaks | Individual | Individual |

A curated list of long-tail keywords for EN 10208 carbon steel pipes, covering specifications, applications, and material properties, presented in a multi-column layout.

Note: EN 10208 covers seamless and welded carbon steel pipes for combustible fluid pipelines. For detailed specifications, refer to EN 10208-1 or EN 10208-2 standards or contact a certified supplier.

EN 10208 carbon steel pipes are critical for industries requiring reliable and safe transport of combustible fluids under specific pressures.

Used in gas supply systems for safe and efficient natural gas transport.

Ideal for oil pipelines in mining and energy sectors.

Used for transporting chemical fluids under controlled pressures.

Applied in power plants for fluid transport in energy systems.

Supports fluid transport in mining operations under pressure.

Used in large-scale pipeline networks for urban and industrial systems.

Din 1629 seamless carbon steel pipes (st37, st44, ...

Din 2391 seamless precision steel tubes offer high...

Din 17175 seamless steel tubes in grades st35.8, s...