Cold-Drawn Tubes for Hydraulic and Automotive Applications

EN 10305-1 seamless precision steel tubes are cold-drawn tubes designed for high-precision applications in hydraulic systems, automotive components, and mechanical engineering. Specified under the European standard EN 10305-1, these tubes are characterized by precise dimensional tolerances and excellent surface quality, making them ideal for applications requiring tight fit and reliability.

Manufactured from hot-finished seamless tubes via cold drawing, EN 10305-1 tubes offer outer diameters from 4 mm to 380 mm and wall thicknesses from 0.5 mm to 40 mm. Common grades include E235, E355, and 42CrMo4, with designations like +N (normalized) or +SR (stress-relieved) indicating delivery conditions. These tubes are tailored for hydraulic steel tubing and automotive precision tubes, ensuring high strength, toughness, and weldability.

The cold-drawing process ensures superior dimensional accuracy (tolerances as tight as ±0.08 mm for outer diameter) and a smooth surface finish (Ra

Compared to welded precision tubes (EN 10305-2) or general-purpose pipes like ASTM A53, EN 10305-1 seamless tubes provide enhanced structural integrity due to the absence of welds, making them ideal for high-pressure systems. Optional coatings or galvanization improve corrosion resistance, extending service life in harsh environments. They are widely used in industries such as automotive, furniture, and general engineering for their precision and durability.

EN 10305-1 seamless precision steel tubes address challenges like precise component fit and high-pressure fluid transport, offering a cost-effective solution for engineers requiring reliable, high-quality tubing in demanding applications. Their compliance with strict standards ensures performance and longevity in critical systems.

What is EN 10305-1 E235 Carbon Steel Pipes & Tube?

EN 10305-1 E235 is one of the grades in this precision tube range.

EN 10305-1 seamless precision steel tubes are cold-drawn tubes designed for high-precision applications in hydraulic systems, automotive components, and mechanical engineering. Specified under the European standard EN 10305-1, these tubes are characterized by precise dimensional tolerances and excellent surface quality, making them ideal for applications requiring tight fit and reliability.

Manufactured from hot-finished seamless tubes via cold drawing, EN 10305-1 tubes offer outer diameters from 4 mm to 380 mm and wall thicknesses from 0.5 mm to 40 mm. Common grades include E235, E355, and 42CrMo4, with designations like +N (normalized) or +SR (stress-relieved) indicating delivery conditions. These tubes are tailored for hydraulic steel tubing and automotive precision tubes, ensuring high strength, toughness, and weldability.

The cold-drawing process ensures superior dimensional accuracy (tolerances as tight as ±0.08 mm for outer diameter) and a smooth surface finish (Ra

Compared to welded precision tubes (EN 10305-2) or general-purpose pipes like ASTM A53, EN 10305-1 seamless tubes provide enhanced structural integrity due to the absence of welds, making them ideal for high-pressure systems. Optional coatings or galvanization improve corrosion resistance, extending service life in harsh environments. They are widely used in industries such as automotive, furniture, and general engineering for their precision and durability.

EN 10305-1 seamless precision steel tubes address challenges like precise component fit and high-pressure fluid transport, offering a cost-effective solution for engineers requiring reliable, high-quality tubing in demanding applications. Their compliance with strict standards ensures performance and longevity in critical systems.

EN10305-4 E235 E355 Cold drawn seamless precision tube

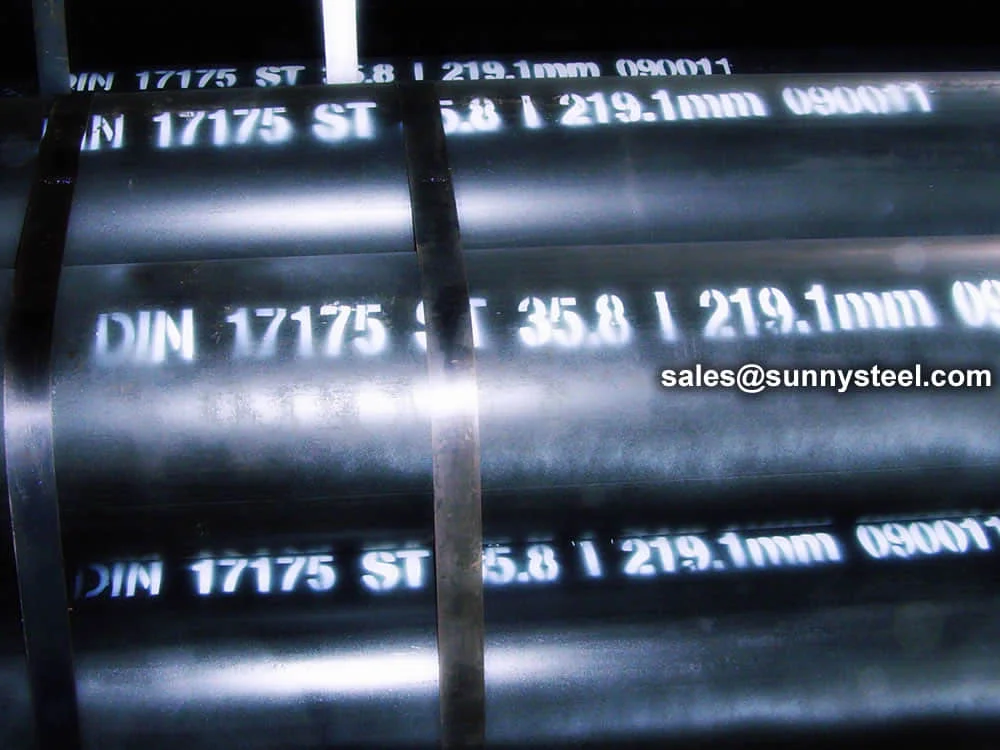

Bright‑annealed, bright‑normalised seamless cold‑drawn precision tubes per DIN2391 ST37.4/ST52.4 and EN10305‑1 (E 235/E 355), ideal for hydraulic and automotive applications.

DIN 2391 defines cold‑drawn, bright‑annealed/normalised, seamless precision tubes (ST37.4, ST52.4) with tight tolerances & smooth surfaces.

EN 10305‑1 covers seamless cold‑drawn precision tubes (E 235, E 355) with strict OD/WT tolerances, hard surfaces, excellent concentricity.

EN 10305‑2 specifies welded-and‑drawn precision tubes mainly for automotive use—prop shafts, cam/driveshafts—with smooth finish and dimensional accuracy.

Finishes include annealed & pickled, bright-annealed, mechanically or electro‑polished. Ends: tapered/plain, square cut, burr-free, with plastic caps.

Typical OD range: 4–120 mm; WT: 0.5–15 mm; excellent tolerances OD ±0.03 mm, WT ±10% per DIN/EN.

Applications: hydraulic systems, precision machinery, automotive, pneumatic cylinders, heavy trucks, agricultural & construction equipment.

Key Benefits

High Precision

Tight tolerances ensure precise fit in hydraulic and automotive systems.

Smooth Surface

Low roughness (Ra

High Strength

Excellent mechanical properties for high-pressure applications.

Corrosion Resistance

Optional coatings enhance durability in harsh environments.

Weldability

Good weldability for easy integration into systems.

Cost-Effective

Precision manufacturing reduces material waste and machining needs.