GB steel pipes

Chinese National Standard Industrial Solutions

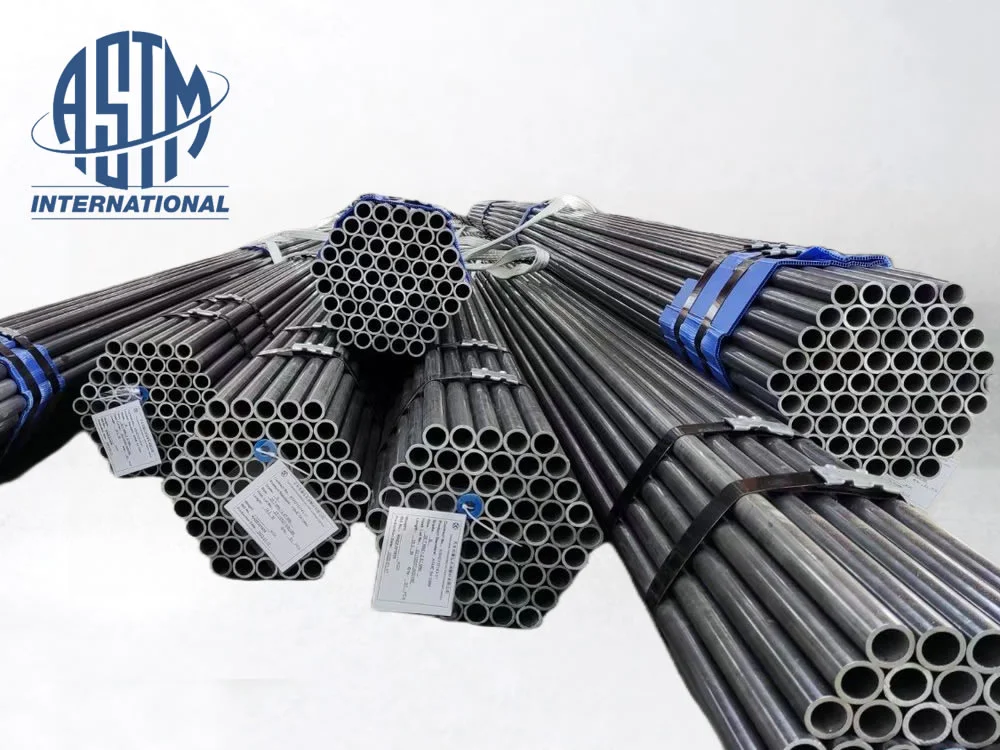

High-quality steel pipes manufactured to Chinese GB standards, ensuring superior strength, durability, and reliability for diverse industrial applications including construction, fluid transport, and energy sectors.