Seamless Carbon Steel Pipes For Fluid Transportation

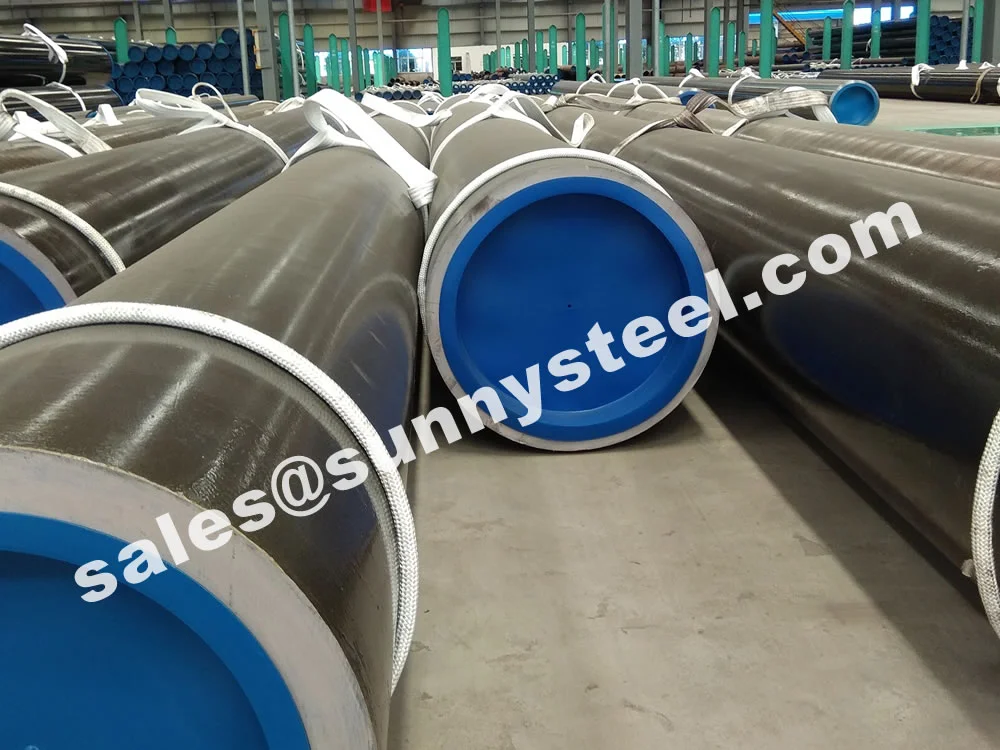

Gb 8163 steel pipes, compliant with gb/t 8163-2018, are seamless carbon steel pipes designed for fluid transportation, ideal for conveying water, oil, gas, and other fluids in industries like petroleum and chemical engineering.

Seamless Carbon Steel Pipes For Fluid Transportation

Gb 8163 steel pipes, compliant with gb/t 8163-2018, are seamless carbon steel pipes designed for fluid transportation, ideal for conveying water, oil, gas, and other fluids in industries like petroleum and chemical engineering.

GB/T 8163-2008 fluid transport seamless steel pipes are commonly used in various industries, including structure steel, fluid pipe, boiler pipe, gas pipe, and oil pipe.

GB 8163 steel pipes, compliant with the Chinese national standard GB/T 8163-2018, are seamless carbon steel pipes designed for fluid transportation pipes, suitable for conveying water, oil, gas, and other fluids. These pipes are widely used in industries such as petroleum, natural gas, chemical engineering, and power generation due to their high strength, durability, and smooth internal surfaces.

Manufactured through hot-rolling or cold-drawing processes, GB/T 8163 seamless pipes are available in outer diameters from 21.3 mm to 914 mm and wall thicknesses from 2 mm to 60 mm, as per GB/T 17395. Common steel grades include 10#, 20#, Q345B, and 27SiMn, with 20# and Q345B being popular for their balance of mechanical properties and cost-effectiveness. These pipes are designed to withstand various temperatures and pressures, making them ideal for fluid transportation applications.

GB 8163 steel pipes undergo rigorous testing, including tensile, impact, flattening, and hydrostatic tests, to ensure compliance with GB/T 8163-2018 standards. Optional surface treatments like galvanizing, black painting, or anti-corrosion coatings enhance durability in harsh environments. The seamless construction ensures no weld seams, providing uniform strength and leak-proof performance for fluid transport.

Compared to international standards like ASTM A106 or ASTM A53, GB/T 8163 pipes are tailored for fluid transportation with similar mechanical properties but optimized for Chinese industrial requirements. For example, grade 20# is comparable to ASTM A106 Grade B, and Q345B aligns with ASTM A572 Gr.50. These pipes offer a cost-effective solution for fluid conveyance, addressing challenges like high-pressure and corrosive environments. They are widely used in Asia and globally due to their reliability and compliance with stringent quality standards.

GB 8163 steel pipes are a preferred choice for engineers and manufacturers in fluid transportation projects, ensuring efficient and safe delivery of liquids and gases in demanding industrial applications.

| Steel Grade | C (%) |

Si (%) |

Mn (%) |

P (%) |

S (%) |

Cr (%) |

Ni (%) |

Cu (%) |

Mo (%) |

|---|---|---|---|---|---|---|---|---|---|

| 10 | 0.07–0.14 | 0.17–0.37 | 0.35–0.65 | ≤0.035 | ≤0.035 | ≤0.15 | ≤0.25 | ≤0.25 | — |

| 20 | 0.17–0.24 | 0.17–0.37 | 0.35–0.65 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | ≤0.25 | — |

| Q345 | 0.12–0.20 | 0.20–0.55 | 1.20–1.60 | ≤0.045 | ≤0.045 | ≤0.30 | ≤0.50 | ≤0.30 | ≤0.10 |

| 45 | 0.42–0.50 | 0.17–0.37 | 0.50–0.80 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | ≤0.25 | — |

| 20Cr | 0.18–0.24 | 0.17–0.37 | 0.50–0.80 | ≤0.035 | ≤0.035 | 0.70–1.00 | ≤0.30 | ≤0.25 | — |

The Carbon Equivalent Value (CEV) of Q345, Q390, Q420 and Q460 shall be calculated using the following formula:

| Grade | Quality Levels | Tensile Properties | Impact Properties | |||

|---|---|---|---|---|---|---|

| Tensile strength Rm | Lower yield strength ReL | Elongation A | Impact temperature | Impact energy KV2 | ||

| 10 | — | 335 – 475 MPa | 205 MPa min | 24 % min | — | — |

| 20 | — | 410 – 530 MPa | 245 MPa min | 20 % min | — | — |

| Q345 | A | 470 – 630 MPa | 345 MPa min | 20 % min | — | — |

| B | +20 ℃ | 34 J | ||||

| C | 21 % min | 0 ℃ | ||||

| D | -20 ℃ | |||||

| E | -40 ℃ | 27 J | ||||

| Q390 | A | 490 – 650 MPa | 390 MPa min | 18 % min | — | — |

| B | +20 ℃ | 34 J | ||||

| C | 19 % min | 0 ℃ | ||||

| D | -20 ℃ | |||||

| E | -40 ℃ | 27 J | ||||

| Q420 | A | 520 – 680 MPa | 420 MPa min | 18 % min | — | — |

| B | +20 ℃ | 34 J | ||||

| C | 19 % min | 0 ℃ | ||||

| D | -20 ℃ | |||||

| E | -40 ℃ | 27 J | ||||

| Q460 | C | 550 – 720 MPa | 460 MPa min | 17 % min | 0 ℃ | 34 J |

| D | -20 ℃ | |||||

| E | -40 ℃ | 27 J | ||||

| Types of steel tubes | Outer diameter | Wall thickness | ||

|---|---|---|---|---|

| Cold-rolled tubes | Tube sizes(mm) | Tolerances(mm) | Tube sizes (mm) | Tolerances(mm) |

| >30 - 50 | ±0.3 | ≤30 | ±10% | |

| >50 - 219 | ±0.8% | |||

| Hot-rolled tubes | >219 | ±1.0% | >20 | ±10% |

| Processing Designation | Symbol | Description |

|---|---|---|

| Cold-finished/hard (cold-finished as-drawn) |

BK | No heat treatment after the last cold-forming process. The tubes therefore have only low deformability. |

| Cold-finished/soft (lightly cold-worked) |

BKW | After the last heat treatment there is a light finishing pass (cold drawing). With proper subsequent processing, the tube can be cold-formed (e.g. bent, expanded) within certain limits. |

| Annealed | GBK | After the final cold-forming process the tubes are annealed in a controlled atmosphere or under vacuum. |

| Normalized | NBK | The tubes are annealed above the upper transformation point in a controlled atmosphere or under vacuum. |

Yield point requirements for seamless precision steel tubes vary significantly based on their delivery conditions, directly influencing their mechanical performance in industrial applications. These differences are critical for engineers selecting materials for specific load-bearing or forming needs.

For tubes delivered in the annealed (GBK) condition, the yield point is specified to be at least 50% of the ultimate tensile strength. This lower yield ratio ensures excellent ductility and formability, making GBK tubes suitable for applications requiring bending, flanging, or other cold-working processes where flexibility is paramount.

In contrast, tubes delivered in cold-finished/hard (BK) condition exhibit a significantly higher yield point due to work hardening from the drawing process. It is recommended that their yield point be ≥ 80% of the tensile strength. This high yield ratio provides enhanced rigidity and load-bearing capacity, ideal for structural components where dimensional stability under stress is critical.

Cold-finished/soft (BKW) condition represents a middle ground, with a recommended yield point of ≥ 70% of the tensile strength. This balance of strength and ductility makes BKW tubes versatile for applications that require both moderate formability and resistance to deformation, such as precision machinery parts or hydraulic system components.

These yield point specifications—tied directly to the degree of deformation during manufacturing—ensure that engineers can select the optimal delivery condition based on their application’s mechanical demands, whether prioritizing formability (GBK), maximum strength (BK), or a balanced performance (BKW).

| Steel Designation | Pipe Body (Seamless & Welded Pipe) | Spiral Weld | Whole Pipe | ||||

|---|---|---|---|---|---|---|---|

| Plastic Limit R10.5 (N/mm²) |

Tensile Strength Rm (N/mm² min.) |

R10.5/Rm (Max) | Elongation A (%) min. |

HFW, SAW, COW Tensile Strength Rm (N/mm² min.) |

SAW, COW Bending Mandrel Diameter |

||

|

L245NB L245MB |

245 to 440 | 415 |

0.80 0.85 |

22 | Same as pipe body | 3T | Every pipe must pass pressure test with no leaks or deformations |

|

L290NB L290MB |

290 to 440 | 415 |

0.85 0.85 |

21 | 3T | ||

|

L360NB L360QB L360MB |

360 to 510 | 460 |

0.85 0.88 0.85 |

20 | 4T | ||

|

L415NB L415QB L415MB |

415 to 565 | 520 |

0.85 0.88 0.85 |

18 | 5T | ||

|

L450QB L450MB |

450 to 570 | 535 |

0.90 0.87 |

18 | 6T | ||

|

L485QB L485MB |

485 to 605 | 570 |

0.90 0.90 |

18 | 6T | ||

|

L555QB L555MB |

555 to 675 | 625 |

0.90 0.90 |

18 | 6T | ||

| Type of Inspection or Test | Frequency of Testing |

|---|---|

| Chemical analysis | One sample per heat number |

| Tensile test | One sample on each of the two steel pipes per lot |

| Impact test | Three samples on each of the two steel pipes per lot (for low alloy high strength structural steel pipes with an outside diameter of not less than 70mm, and a wall thickness of not less than 6.5mm) |

| Flattening test | One sample on each of the two steel pipes per lot (for steel pipes in grades 10, 20, Q345, Q390, with an outside diameter D>22~600mm, and S/D ratio not greater than 10%) |

| Flaring test | One sample on each of the two steel pipes per lot (for steel pipes in grades 10, 20, Q345, with an outside diameter of not greater than 76mm, and a wall thickness of not greater than 8mm) |

| Bending test | One sample on each of the two steel pipes per lot (for steel pipes with an outside diameter not greater than 22mm) |

| Hydrostatic test | Each pipe, dwell time is not less than 5s, can be replaced by eddy current test |

| Eddy current test | Each pipe |

| Magnetic flux leakage detection | Each pipe, can be replaced by eddy current test |

| Ultrasonic test | Each pipe |

| Dimension and shape | It should be measured with a measuring tool that meets accuracy requirements |

| Inner and outer surfaces | It should be visually inspected under sufficient lighting conditions |

GB/T 8163-2008 specifies the requirements for seamless steel pipes used for fluid transportation, while ASTM A106 and ASTM A53 are American standards for seamless carbon steel pipes used in various industries.

A curated list of long-tail keywords for GB 8163 steel pipes, covering specifications, applications, and material properties, presented in a multi-column layout.

Note: GB/T 8163-2018 covers seamless steel pipes for fluid transportation. For detailed specifications, refer to the GB/T 8163-2018 standard or contact a certified supplier.

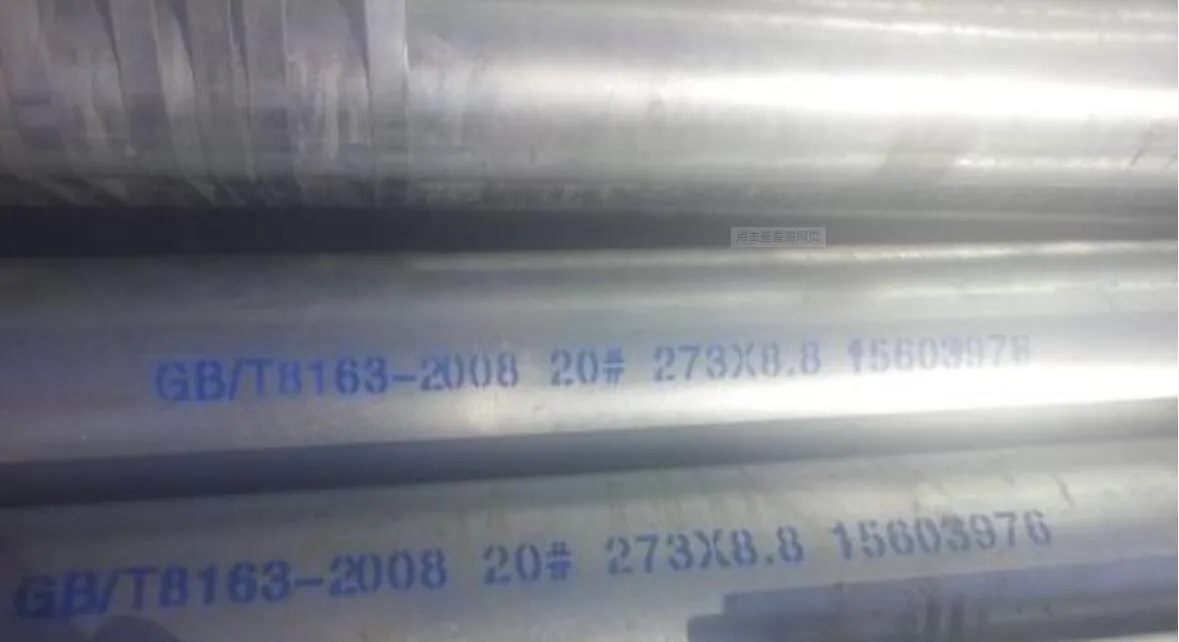

Marked with standard, grade, OD×WT, heat number, and manufacturer ID. Orders specify standard,

grade, dimensions, length, and test

certificates.

Marked with standard, grade, OD×WT, heat number, and manufacturer ID. Orders specify standard,

grade, dimensions, length, and test

certificates.

GB/T 8163 seamless steel pipes are critical for industries requiring reliable fluid transportation under various pressures and conditions.

Used for oil transportation pipelines and equipment.

Applied in gas transmission pipelines.

Used for transporting chemicals and gases.

Utilized in steam and fluid transport systems.

Used for municipal and industrial water transport.

Applied in various fluid conveyance systems.

15crmo seamless boiler tubes, compliant with gb/t ...

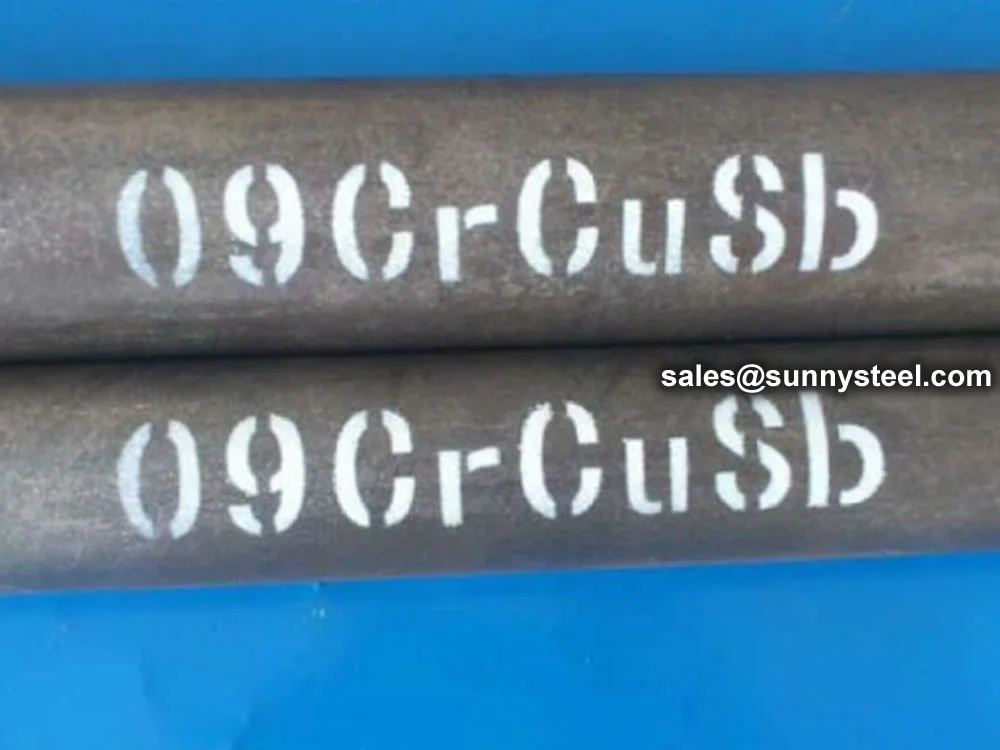

09crcusb seamless steel pipes (nd steel), complian...

35crmo seamless steel pipes, compliant with gb/t 8...

12cr5moi seamless steel tubes, compliant with gb/t...

Gb 9948 seamless steel pipes, compliant with gb/t ...