Heat‑treated Seamless Carbon & Alloy Steel Tubes Designed For High-temperature, High-pressure Steam Systems.

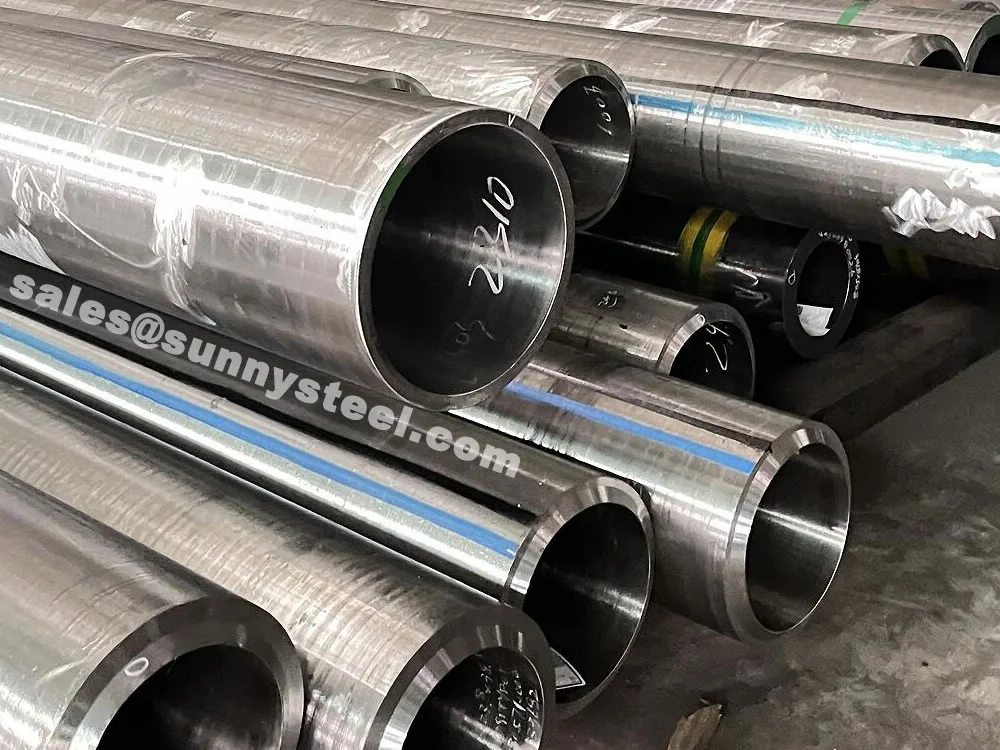

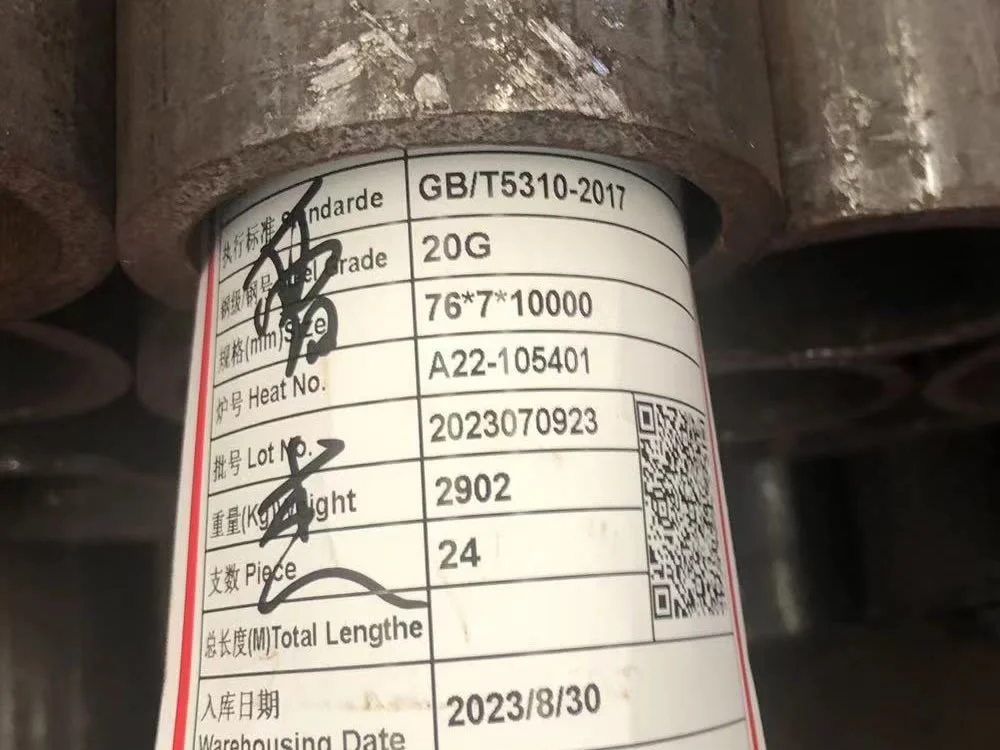

Gb 5310 seamless tubes (e.g., 20g, 15mog, 25mng) are heat‑treated, high-strength pipes engineered for high‑pressure boilers, delivering robust mechanical performance, corrosion resistance, and certified quality.

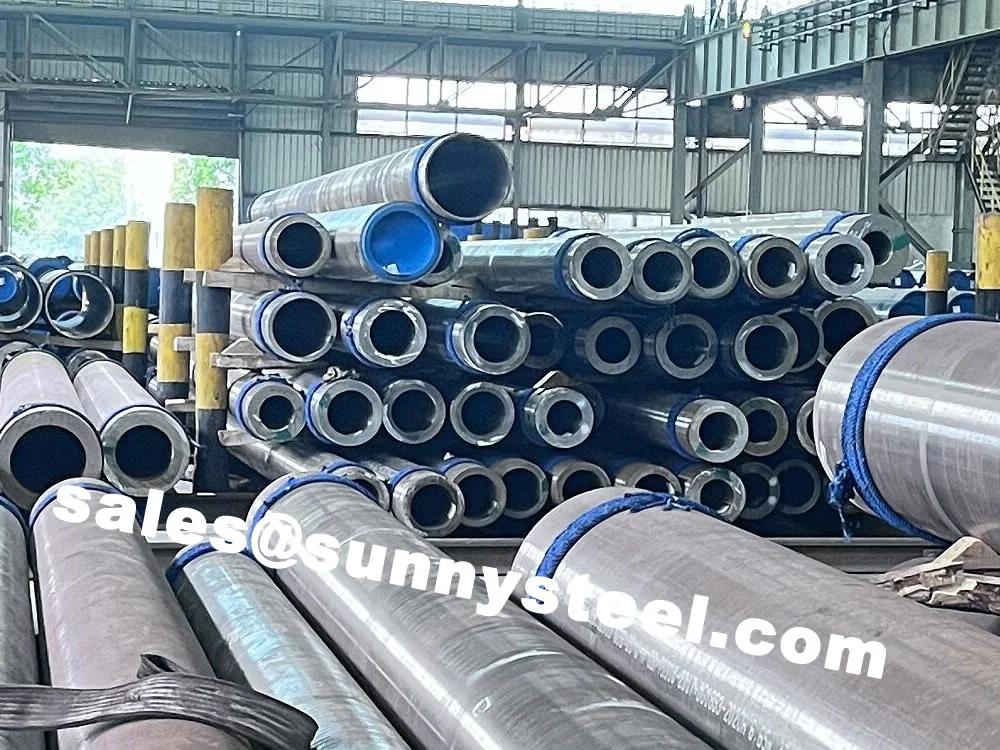

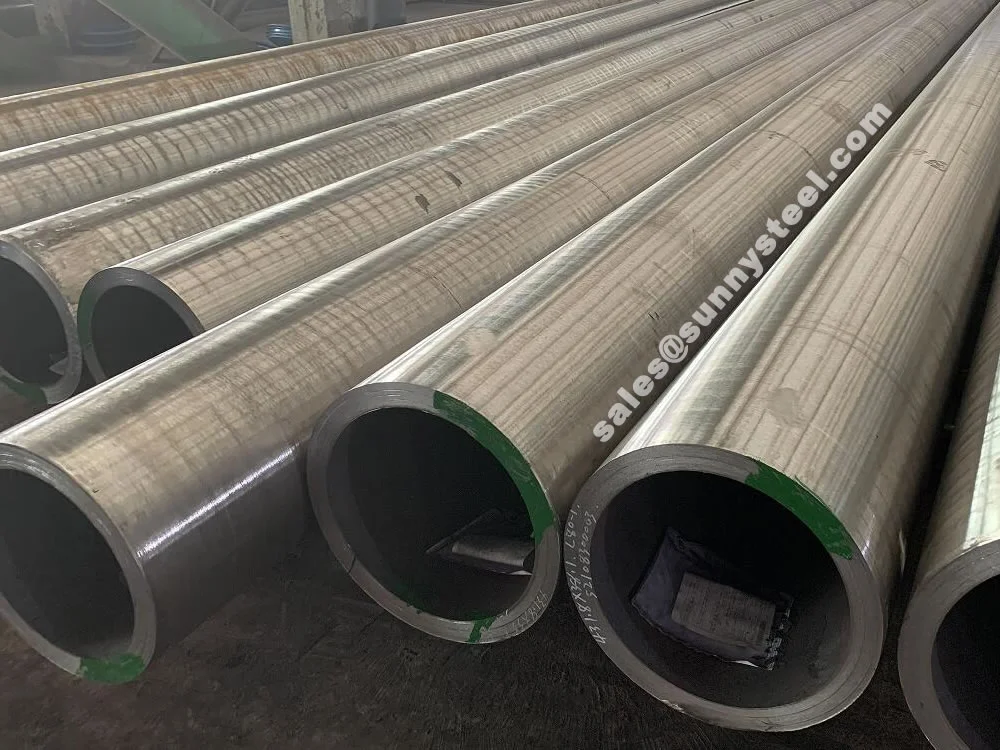

GB 5310 high-pressure boiler tubes, compliant with the Chinese national standard GB/T 5310-2017, are seamless steel tubes designed for high-pressure and high-temperature boiler applications. These tubes are used in critical components such as superheaters, reheaters, steam pipelines, and economizers in power plants and industrial boiler systems, offering exceptional strength, corrosion resistance, and thermal stability.

Manufactured through hot-rolling (extrusion, expansion) or cold-drawing (rolling) processes, GB/T 5310 seamless tubes are available in outer diameters from 23 mm to 1500 mm and wall thicknesses from 2.8 mm to 150 mm, as per GB/T 5310-2017. Common steel grades include 20G, 15MoG, 12Cr1MoVG, and 10Cr9Mo1VNbN, with 20G being the most widely used due to its excellent mechanical properties and weldability. These tubes are designed for working pressures above 9.8 MPa and temperatures between 450°C and 650°C, with 20G tubes suitable for long-term use at wall temperatures ≤450°C for heating surfaces and ≤425°C for headers and steam pipes.

GB 5310 boiler tubes undergo rigorous testing, including hydraulic, ultrasonic, tensile, impact, and flattening tests, to ensure compliance with GB/T 5310-2017 standards. Surface treatments such as varnishing, shot blasting, or coating enhance corrosion resistance, making them ideal for harsh high-pressure boiler environments. The seamless design ensures uniform strength, eliminating weak points and ensuring leak-proof performance critical for boiler safety.

Compared to international standards like ASTM A335, EN 10216-2, or DIN 17175, GB/T 5310 tubes are optimized for high-pressure boiler applications, with 20G closely aligning with ASTM A106B and ST45.8 for similar uses. These tubes offer a reliable and cost-effective solution for power generation and petrochemical industries, addressing challenges like high-temperature creep and oxidation. They are widely used in China and globally, particularly in Asia, due to their durability and adherence to strict standards.

GB 5310 high-pressure boiler tubes are essential for engineers and manufacturers in power plants, petrochemical facilities, and industrial boiler systems, ensuring efficient steam generation and safe fluid transport under extreme conditions.

Heat treatment is a highly effective means of improving and modifying the properties of 15CrMo alloy round steel. It plays a very important role in product reliability and economy. Heat treatment of 15CrMo alloy round steel usually includes ordinary heat treatment (annealing, normalising, quenching, tempering) and surface heat treatment (surface quenching and chemical heat treatment - carburising, nitriding, metallising, etc.).

In mechanical engineering, many machine parts, such as crankshafts, gears, camshafts of internal combustion engines and gears in important reduction gears, require not only sufficient toughness, plasticity and bending strength in the core, but also a high surface thickness within a certain thickness. hardness, high wear resistance and high fatigue strength. It is difficult to meet the above performance requirements simultaneously with the above various overall heat treatment methods, and the use of surface heat treatment is the most effective method to meet these performance requirements simultaneously.

Surface heat treatment is a heat treatment method that changes the surface properties of 15CrMo alloy round steel by changing the structure of the surface layer.

Surface quenching is a heat treatment that gradually changes the surface structure without changing the chemical composition of the surface. It can be carried out by high-frequency, medium-frequency or power-frequency induction heating method or flame heating method. The common feature is that the surface of 15CrMo alloy round steel is quickly heated to the quenching temperature, and when the heat is not transferred to the core of the part, it is quickly cooled, so that the surface hardness is high, but the core still has high toughness.

Chemical heat treatment is a heat treatment method that changes the chemical composition and structure of the surface layer of 15CrMo alloy round steel. Chemical heat treatment can be divided into methods such as carburizing, nitriding, carbonitriding and metallising according to the different elements infiltrated on the surface of 15CrMo alloy round steel. It is very effective in improving and enhancing the wear resistance, corrosion resistance and fatigue resistance of 15CrMo alloy round steel. At present, chemical heat treatment has developed rapidly, and there are many applications of new technologies.

Engineered to withstand temperatures up to 650°C for reliable boiler performance.

Durable seamless design reduces maintenance and replacement costs.

Ideal for superheaters, reheaters, and steam pipelines in power plants.

Enhanced by coatings to withstand harsh boiler environments.

Hydraulic, ultrasonic, and tensile tests ensure quality and safety.

Ensures uniform strength and leak-proof performance.

| Steel Grade | C (%) |

Si (%) |

Mn (%) |

S (%) |

P (%) |

Cr (%) |

Mo (%) |

V (%) |

Ti (%) |

B (%) |

W (%) |

Ni (%) |

Al (%) |

Nb (%) |

N (%) |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20G | 0.17-0.23 | 0.17-0.37 | 0.35-0.65 | 0.015 | 0.025 | — | — | — | — | — | — | — | — | — | — | |

| 20 MnG | 0.17-0.24 | 0.17-0.37 | 0.70-1.00 | 0.015 | 0.025 | — | — | — | — | — | — | — | — | — | — | — |

| 25MnG | 0.22-0.27 | 0.17-0.37 | 0.70-1.00 | 0.015 | 0.025 | — | — | — | — | — | — | — | — | — | — | |

| 15MoG | 0.12-0.20 | 0.17-0.37 | 0.40-0.80 | 0.015 | 0.025 | — | 0.25-0.35 | — | — | — | — | — | — | — | — | |

| 20MnG | 0.15-0.25 | 0.17-0.37 | 0.40-0.80 | 0.015 | 0.025 | — | 0.44-0.65 | — | — | — | — | — | — | — | — | |

| 12CrMoG | 0.08-0.15 | 0.17-0.37 | 0.40-0.70 | 0.015 | 0.025 | 0.40-0.70 | 0.40-0.55 | — | — | — | — | — | — | — | — | |

| 15CrMoG | 0.12-0.18 | 0.17-0.37 | 0.40-0.70 | 0.015 | 0.025 | 0.80-1.10 | 0.40-0.55 | — | — | — | — | — | — | — | — | |

| 12Cr2MoG | 0.08-0.15 | ≤0.60 | 0.40-0.60 | 0.015 | 0.025 | 2.00-2.50 | 0.90-1.13 | — | — | — | — | — | — | — | — | |

| 12Cr1MoVG | 0.08-0.15 | 0.17-0.37 | 0.40-0.70 | 0.010 | 0.025 | 0.90-1.20 | 0.25-0.35 | 0.15-0.30 | — | — | — | — | — | — | — | |

| 12Cr2MoWVTiB | 0.08-0.15 | 0.45-0.75 | 0.45-0.65 | 0.015 | 0.025 | 1.60-2.10 | 0.50-0.65 | 0.28-0.42 | 0.08-0.18 | 0.002-0.008 | 0.30-0.55 | — | — | — | — | |

| 10Cr9Mo1VNbN | 0.08-0.12 | 0.20-0.50 | 0.30-0.60 | 0.010 | 0.020 | 8.00-9.50 | 0.85-1.05 | 0.18-0.25 | — | — | — | ≤0.040 | ≤0.040 | 0.06-0.10 | 0.03-0.07 |

| Grade | Tensile strength (Mpa) |

Yield point(Mpa) not less than |

Elongation(%) not less than |

Impact(J) not less than |

|---|---|---|---|---|

| 20G | 410-550 | 245 | 24/22 | 40/27 |

| 25MnG | 485-640 | 275 | 20/18 | 40/27 |

| 15MoG | 450-600 | 270 | 22/20 | 40/27 |

| 20MnG | 415-665 | 220 | 22/20 | 40/27 |

| 12CrMoG | 410-560 | 205 | 21/19 | 40/27 |

| 12Cr2MoG | 450-600 | 280 | 22/20 | 40/27 |

| 12Cr1MoVG | 470-640 | 255 | 21/19 | 40/27 |

| 12Cr2MoWVTiB | 540-735 | 345 | 18 | 40/27 |

| 10Cr9Mo1VNb | ≥585 | 415 | 20 | 40 |

| 1Cr18Ni9 | ≥520 | 206 | 35 | — |

| 1Cr19Ni11Nb | ≥520 | 206 | 35 | — |

| No. | Steel Pipe | Heat Treatment |

|---|---|---|

| 1 | 12Ga、20Ga | 880 ℃~940 ℃, Normalizing |

| 2 | 20MnGa、25MnGa | 880 ℃~940 ℃, Normalizing |

| 3 | 15MoGa、20MoGa | 890 ℃~950 ℃, Normalizing |

| 4 | 12CrMoGa | 900 ℃~960 ℃, Normalizing; 650 ℃~730 ℃, Tempering |

| 5 | 15CrMoGa | 900 ℃~960 ℃, Normalizing; 660 ℃~730 ℃, Tempering |

| 6 | 12Cr2MoGa | 900 ℃~960 ℃, Normalizing; 700 ℃~750 ℃, Tempering It can also be heated to 900 °C ~ 960 °C, and the furnace is cooled to 700 °C for more than 1 h, and air-cooled. |

| 7 | 12Cr1MoVGa | 980 ℃~1 020 ℃, Normalizing, 980 °C ~ 1 020 °C normalizing, when the wall thickness is greater than 30 mm, forced cooling; 720 °C ~ 760 °C tempering. |

| 8 | 12Cr2MoWVTiB | 1 000 ℃~1 035 ℃, Normalizing; 760 ℃~790 ℃, Tempering |

| 9 | 07Cr2MoW2VNbB | ≥1 040 ℃, Normalizing, ≥730 ℃, Tempering |

| 10 | 08Cr2Mo1W2VTiB | ≥980 ℃, Normalizing, ≥730 ℃, Tempering |

| 11 | 12Cr3MoVSiTiB | 1 040 ℃~1 060 ℃, Normalizing; 720 ℃~770 ℃, Tempering |

| 12 | 09Ni1MnMoNbCu | 880 ℃~980 ℃, Normalizing, 580 ℃~680 ℃, Tempering |

| 13 | 10Cr9Mo1VNbN | ≥1 040 ℃, Normalizing, ≥730 ℃, Tempering |

| 14 | 10Cr9MoW2VNbBN | ≥1 040 ℃, Normalizing, ≥730 ℃, Tempering |

| 15 | 10Cr11MoW2VNbCu1BN | ≥1 040 ℃, Normalizing, ≥730 ℃, Tempering |

| 16 | 11Cr9Mo1W1VNbBN | 1 040 ℃~1 080 ℃, Normalizing, 740 ℃~780 ℃, Tempering |

| 17 | 15Cr18Ni9b | Solution treatment: solution temperature ≥1 040 °C. |

| 18 | 10Cr18Ni9NbCu3BNb | Solution treatment: solution temperature ≥ 1 100 °C. |

| 19 | 07Cr25Ni21NbNcd | Separate solution treatment: solution temperature ≥ 1 100 °C. |

| 20 | 08Cr18Ni11Nbbd | Solution treatment: solution temperature ≥1 040 °C. |

| 21 | 07Cr18Ni11Nbcd | Separate solution treatment: hot rolling (extrusion, expansion) steel tube solid solution temperature ≥ 1 050 °C, cold drawn (rolled) steel tube solid solution temperature ≥ 1100 °C. |

| 22 | 08Cr18Ni10NbFG | Softening heat treatment before cold working: softening heat treatment temperature should be at least 50 °C higher than solution heat treatment temperature; solution treatment after final cold working: solution temperature ≥1 180 °C |

|

a. The finishing temperature of the hot-rolled steel pipe is at the critical

temperature of the phase transition Ar3 to the upper limit of the temperature

specified in the table, and when the steel pipe is air-cooled, the steel pipe is

considered to be normalized. b. The finishing temperature of the hot-rolled steel pipe meets the solid solution temperature specified in the table. As an alternative to the solid solution treatment method, the steel pipe can be separately quenched by water or cooled by other fast enough methods. c. The solution treatment should be a separate heat treatment, and the heat treatment in the process is not allowed to replace the separate solution treatment. d. According to the requirements of the purchaser, the steel pipes of the grades 07Cr25Ni21NbN, 08Cr19Ni10Nb and 07Cr18Ni11Nb may be subjected to a stabilization heat treatment lower than the initial solution treatment temperature after the solution treatment, and the temperature of the stabilization heat treatment is negotiated between the supplier and the purchaser. |

||

| Country | Standard | Material |

|---|---|---|

| USA | SAE/AISI/UNS | - |

| Germany | DIN,WNr | 15CrMO | 1.7262 |

| China | GB | 15CrMo |

| Japan | JIS | SCM415 |

| France | AFNOR | 15CD4.05 |

| England | BS | 1501-620 | Cr31 |

| Italy | UNI | - |

| Poland | PN | - |

| Czechia | CSN | - |

| Austria | ONORM | - |

| Sweden | SS | - |

| Spain | UNE | - |

| Feature | GB/T 5310 20G | ASTM A335 P11 | EN 10216-2 P265GH |

|---|---|---|---|

| Material Type | Carbon Steel (Seamless) | Alloy Steel (Seamless) | Carbon Steel (Seamless) |

| Temperature Range | ≤450°C (heating surface) | Up to 600°C | Up to 450°C |

| Precision | High | High | High |

| Corrosion Resistance | Good (With coatings) | Excellent | Good |

| Applications | High-pressure boilers | High-temperature boilers | Pressure systems |

| Tensile Strength (MPa) | 410–550 | ≥415 | 410–570 |

| Yield Strength (MPa) | 230–250 | ≥205 | 265 |

| Key Advantage | Cost-effective for high-pressure boilers | Superior high-temperature strength | Precision for pressure systems |

| Feature | GB/T 3087 20# | ASTM A192 | EN 10216-1 P235TR1 |

|---|---|---|---|

| Material Type | Carbon Steel (Seamless) | Carbon Steel (Seamless) | Carbon Steel (Seamless) |

| Temperature Range | ≤480°C (heating surface) | High temperatures | Ambient to moderate |

| Precision | Moderate | High | High |

| Corrosion Resistance | Good (With coatings) | Good (With coatings) | Good (With coatings) |

| Applications | Low/medium-pressure boilers | High-pressure boilers | Fluid transport, pressure systems |

| Tensile Strength (MPa) | 410–550 | ≥325 | 360–500 |

| Yield Strength (MPa) | 235 | ≥180 | 235 |

| Key Advantage | Cost-effective for boilers | High-pressure performance | Precision for pressure systems |

A curated list of long-tail keywords for GB 5310 high-pressure boiler tubes, covering specifications, applications, and material properties, presented in a multi-column layout.

Note: GB/T 5310-2017 covers seamless steel tubes for high-pressure boilers. For detailed specifications, refer to the GB/T 5310-2017 standard or contact a certified supplier.

GB/T 5310 seamless steel tubes are critical for high-pressure boiler systems requiring superior strength and thermal resistance.

Used in superheaters and reheaters for efficient steam generation.

Applied in high-pressure pipelines for fluid transport.

Transports high-pressure steam in power generation systems.

Enhances energy efficiency in boiler systems.

Supports high-pressure fluid transport in chemical plants.

Used in various high-pressure boiler applications.

15crmo seamless boiler tubes, compliant with gb/t ...

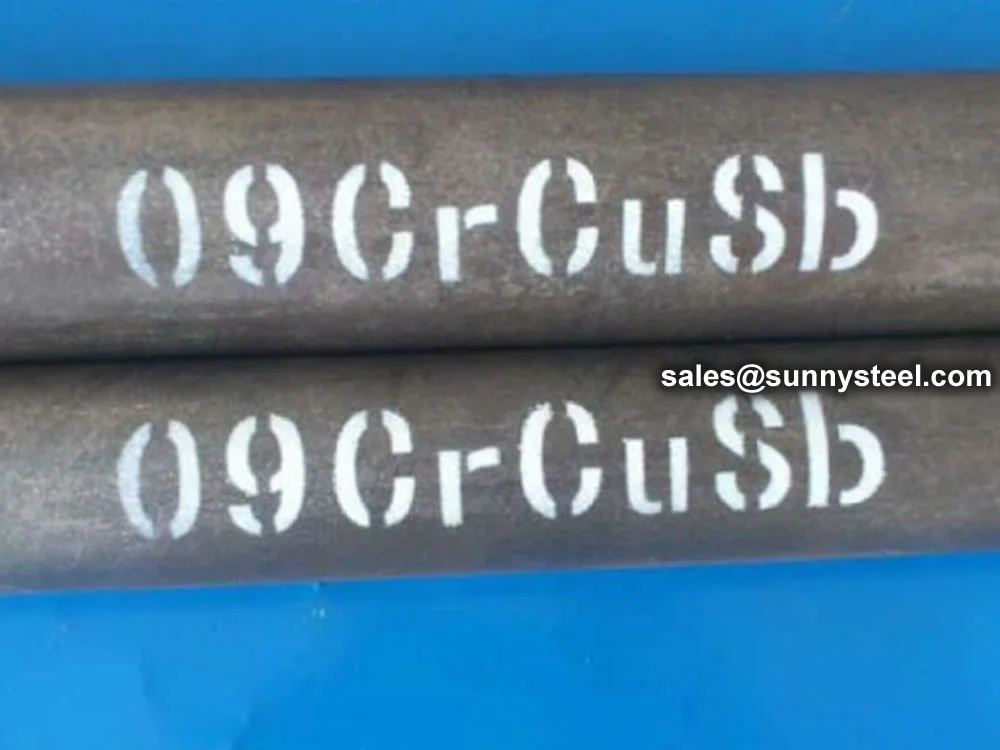

09crcusb seamless steel pipes (nd steel), complian...

35crmo seamless steel pipes, compliant with gb/t 8...

12cr5moi seamless steel tubes, compliant with gb/t...

Gb 9948 seamless steel pipes, compliant with gb/t ...

Gb 8163 steel pipes, compliant with gb/t 8163-2018...