High-quality Tubes For Petroleum Cracking And Refining

Gb 9948 seamless steel pipes, compliant with gb/t 9948-2013, are high-quality carbon and alloy steel tubes designed for petroleum cracking and refining processes, suitable for high-temperature and high-pressure petrochemical applications.

High-quality Tubes For Petroleum Cracking And Refining

Gb 9948 seamless steel pipes, compliant with gb/t 9948-2013, are high-quality carbon and alloy steel tubes designed for petroleum cracking and refining processes, suitable for high-temperature and high-pressure petrochemical applications.

GB 9948 seamless steel pipes, compliant with the Chinese national standard GB/T 9948-2013, are high-quality carbon and alloy steel tubes designed for petroleum cracking and refining processes. These pipes are engineered for high-temperature and high-pressure environments, making them ideal for applications in petroleum refineries, petrochemical plants, and cracking units.

Manufactured through hot-rolling (extrusion, expansion) or cold-drawing (rolling) processes, GB/T 9948 seamless pipes are available in outer diameters from 10 mm to 426 mm and wall thicknesses from 2.0 mm to 40 mm, as per GB/T 17395. Common steel grades include 10, 20, 12CrMo, 15CrMo, 1Cr5Mo, and 12Cr2Mo, with grade 20 being widely used for its excellent balance of strength, toughness, and weldability. These pipes are suitable for operating conditions with temperatures up to 600°C and pressures exceeding 10 MPa, such as in cracking furnaces, heat exchangers, and high-pressure pipelines.

GB 9948 pipes undergo rigorous testing, including hydraulic (up to 20 MPa), tensile, flattening, flaring, impact, ultrasonic, and eddy current tests, to ensure compliance with GB/T 9948-2013 standards. Surface treatments like varnishing, shot blasting, or anti-corrosion coatings enhance durability in aggressive petrochemical environments. The seamless construction ensures uniform strength and leak-proof performance, critical for maintaining safety and efficiency in petroleum cracking processes.

Compared to international standards like ASTM A335 or EN 10216-2, GB/T 9948 pipes are optimized for petroleum cracking applications, with grade 20 aligning closely with ASTM A106B for similar high-temperature uses. These pipes offer a cost-effective, high-performance solution for petrochemical industries, addressing challenges like thermal stress, corrosion, and high-pressure fluid transport. They are widely used in China and exported globally, particularly to regions like the Middle East and Southeast Asia, due to their reliability and adherence to strict standards.

GB 9948 seamless steel pipes are the preferred choice for engineers and manufacturers in petroleum refining, petrochemical processing, and cracking units, ensuring safe and efficient operation under extreme conditions.

GB/T 9948 standard is equivalent to ASTM A335, ASTM A312, etc.

it applies to seamless steel tubes used for furnace tubes, heat exchanger tubes, and pressure pipelines in petrochemicals. GB/T 9948 seamless steel tubes are made of high quality carbon steel or alloy steel materials, which have high strength and excellent mechanical properties. The carbon steel materials main include 10#, 20#. The alloy steel materials main include 12Cr5Mo, 12CrMo, etc. Different materials have different heat treatment process requirements. No matter what the material is used, we will perform heat treatment on the steel pipes before delivery.

Designed to withstand temperatures up to 600°C in cracking processes.

Durable seamless design reduces maintenance costs.

Ideal for petroleum cracking and petrochemical pipelines.

Coatings enhance durability in petrochemical environments.

Hydraulic, ultrasonic, and impact tests ensure quality.

Ensures uniform strength and leak-proof performance.

| Grade | C (%) |

Si (%) |

Mn (%) |

P (≤%) |

S (≤%) |

Cr (%) |

Mo (%) |

Ni (%) |

|---|---|---|---|---|---|---|---|---|

| 10 | 0.07-0.14 | 0.17-0.37 | 0.35-0.65 | 0.035 | 0.035 | ≤0.15 | — | ≤0.25 |

| 20 | 0.17-0.24 | 0.17-0.37 | 0.35-0.65 | 0.035 | 0.035 | ≤0.25 | — | ≤0.25 |

| 15CrMo | 0.12-0.18 | 0.17-0.37 | 0.40-0.70 | 0.035 | 0.035 | 0.80-1.10 | 0.40-0.55 | ≤0.30 |

| 1Cr2Mo | ≤0.15 | 0.50-1.00 | 0.30-0.60 | 0.035 | 0.030 | 2.15-2.85 | 0.45-0.65 | — |

| 1Cr5Mo | ≤0.15 | ≤0.50 | ≤0.60 | 0.035 | 0.030 | 4.00-6.00 | 0.45-0.60 | ≤0.60 |

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Impact Energy (J) | Brinell Hardness (HB) | Delivery Status |

|---|---|---|---|---|---|---|

| 10 | 330-490 | ≥205 | ≥24 | — | — | Normalizing |

| 20 | 410-550 | ≥245 | ≥21 | ≥39 | — | Normalizing |

| 15CrMo | 440-640 | ≥235 | ≥21 | ≥47 | ≤170 | Normalizing + tempering |

| 1Cr2Mo | ≥390 | ≥175 | ≥22 | ≥92 | ≤179 | Normalizing + tempering |

| 1Cr5Mo | ≥390 | ≥195 | ≥22 | ≥92 | ≤187 | Annealing |

| Feature | GB/T 9948 20 | ASTM A335 P11 | EN 10216-2 P265GH |

|---|---|---|---|

| Material Type | Carbon Steel (Seamless) | Alloy Steel (Seamless) | Carbon Steel (Seamless) |

| Temperature Range | Up to 600°C | Up to 600°C | Up to 450°C |

| Pressure Range | >10 MPa | High pressure | Moderate pressure |

| Corrosion Resistance | Good (With coatings) | Excellent | Good |

| Applications | Petroleum cracking, petrochemical | High-temperature boilers | Pressure systems, boilers |

| Tensile Strength (MPa) | 410–550 | ≥415 | 410–570 |

| Yield Strength (MPa) | 245 | ≥205 | 265 |

| Key Advantage | Optimized for petroleum cracking | Superior high-temperature strength | Precision for pressure systems |

| Grade | Heat Treatment |

|---|---|

| 10# | Normalization: Normalizing temperature 880℃-940℃ |

| 20# | Normalization: Normalizing temperature 880℃-940℃ |

| 12CrMo | Normalized and tempered: Normalizing temperature 900℃-960℃, tempering temperature 670℃-730℃ |

| 15CrMo | Normalized and tempered: Normalizing temperature 900℃-960℃, tempering temperature 680℃-730℃ |

| 12Cr5MoI | Full annealing or isothermal annealing |

| Application | OD Range | WT Range | Length Range | Standards |

|---|---|---|---|---|

| Cracking Furnaces | 10-426 mm | 1.5-50 mm | 5-12 m | GB/T 9948, ASTM A335, EN 10216-2 |

| Heat Exchangers | 1/2" – 12" | SCH 40, 80, 160 | Up to 12 m | ASTM A213, A312, GB/T 9948 |

| Transfer Lines | 1/8" – 24" | SCH 40, 80, XXS | Up to 12 m | GB/T 9948, ASTM A335, GOST 9941 |

| Refinery Piping | 10-323 mm | 1.5-40 mm | 5-12 m | GB/T 9948, ASTM A106, EN 10216-2 |

A curated list of long-tail keywords for GB 9948 seamless steel pipes, covering specifications, applications, and material properties, presented in a multi-column layout.

Note: GB/T 9948-2013 covers seamless steel tubes for petroleum cracking. For detailed specifications, refer to the GB/T 9948-2013 standard or contact a certified supplier.

GB/T 9948 seamless steel pipes are essential for petroleum cracking and refining processes, offering superior strength and thermal resistance.

Used in cracking furnaces for hydrocarbon processing.

Transports high-pressure fluids in refining processes.

Facilitates heat transfer in petrochemical plants.

Used in high-pressure refining units.

Supports corrosive fluid transport in chemical plants.

Ensures reliable fluid transport in petrochemical systems.

15crmo seamless boiler tubes, compliant with gb/t ...

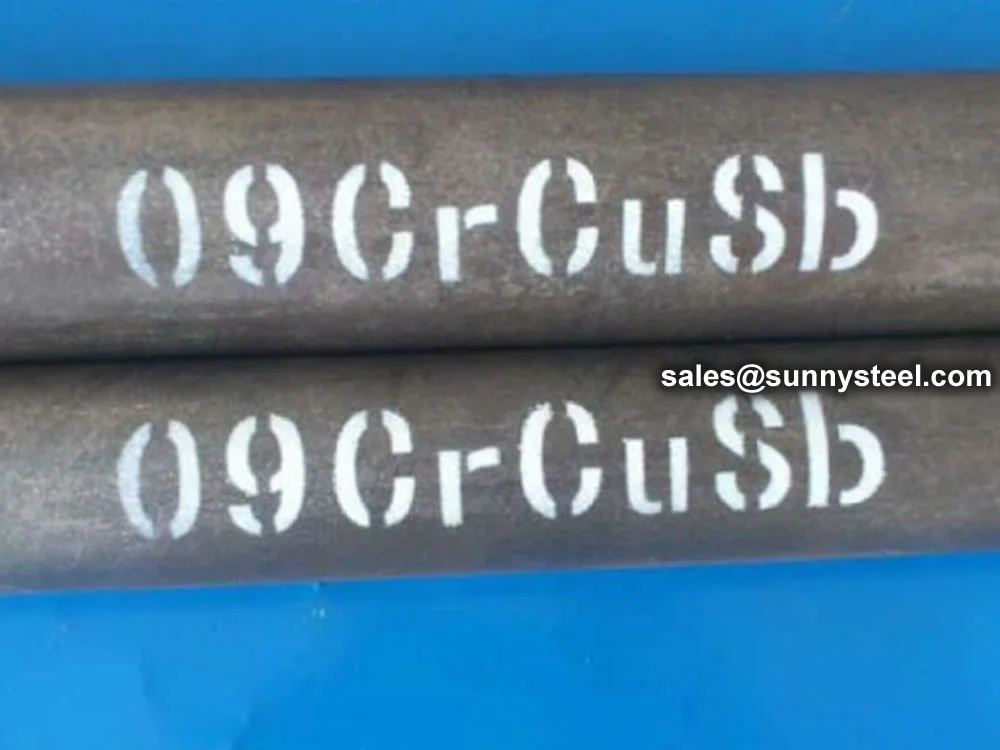

09crcusb seamless steel pipes (nd steel), complian...

35crmo seamless steel pipes, compliant with gb/t 8...

12cr5moi seamless steel tubes, compliant with gb/t...

Gb 8163 steel pipes, compliant with gb/t 8163-2018...