High-strength Alloy Tubes For Mechanical And Industrial Applications

35crmo seamless steel pipes, compliant with gb/t 8162 and gb/t 18248 standards, are high-strength alloy steel tubes designed for high-load mechanical and industrial applications, offering excellent toughness and creep strength up to 500°c.

High-strength Alloy Tubes For Mechanical And Industrial Applications

35crmo seamless steel pipes, compliant with gb/t 8162 and gb/t 18248 standards, are high-strength alloy steel tubes designed for high-load mechanical and industrial applications, offering excellent toughness and creep strength up to 500°c.

Manufactured through hot-rolling or cold-drawing processes, 35CrMo seamless pipes are available in outer diameters from 50 mm to 457 mm and wall thicknesses from 0.5 mm to 55 mm, with customizable lengths (e.g., 5.8 m or 12 m for container shipping). Common surface treatments include black painting, galvanizing, or anti-corrosion coatings to enhance durability. These pipes undergo rigorous testing, including tensile, impact, hardness, and non-destructive tests (e.g., ultrasonic, hydrostatic), to ensure quality and reliability in critical applications

The 35CrMo grade is widely used in industries such as petroleum, chemical, power, and automotive for manufacturing high-load components like crankshafts, gears, transmission shafts, and gas cylinders. Its international equivalents include 34CrMo4 (EN 10297-1), SCM435 (JIS), and similar grades, offering comparable high-strength properties. Compared to 40Cr, 35CrMo has higher hardenability and better performance under high-temperature and high-pressure conditions, though its welding performance is relatively poor, requiring preheating and post-weld heat treatment

35CrMo seamless steel pipes are a cost-effective, durable solution for applications requiring high strength, wear resistance, and toughness. They are widely produced in China and exported globally, supported by a robust supply chain and strict quality control, making them a preferred choice for engineers and manufacturers in high-demand sectors.

Tensile strength ≥985 MPa for demanding applications.

Excellent toughness at low temperatures (-20°C).

Operates reliably up to 500°C.

Superior hardenability compared to 40Cr.

Uniform strength and leak-proof performance.

Wide availability and durable design reduce costs.

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.32–0.40 |

| Silicon (Si) | 0.17–0.37 |

| Manganese (Mn) | 0.40–0.70 |

| Phosphorus (P) | ≤0.030 |

| Sulfur (S) | ≤0.030 |

| Chromium (Cr) | 0.80–1.10 |

| Molybdenum (Mo) | 0.15–0.25 |

| Property | Value |

|---|---|

| Tensile Strength (MPa) | ≥985 |

| Yield Strength (MPa) | ≥835 |

| Elongation, min (%) | ≥12 |

| Hardness (HBW, annealed) | ≤229 |

| Impact Energy (J, -20°C) | ≥35 |

| Feature | 35CrMo (GB/T 8162) | 40Cr (GB/T 8162) | 34CrMo4 (EN 10297-1) |

|---|---|---|---|

| Material Type | Low-Alloy Steel | Low-Alloy Steel | Cr-Mo Alloy Steel |

| Temperature Range | Up to 500°C | Up to 450°C | Up to 500°C |

| Tensile Strength (MPa) | ≥985 | ≥980 | ≥1000 |

| Yield Strength (MPa) | ≥835 | ≥785 | ≥800 |

| Hardenability | High | Moderate | High |

| Applications | Gears, crankshafts, gas cylinders | Shafts, gears | Gas cylinders, structural parts |

| Key Advantage | High creep strength | Good machinability | High toughness at low temp |

A curated list of long-tail keywords for 35CrMo seamless steel pipes, covering specifications, applications, and material properties, presented in a multi-column layout.

Note: 35CrMo seamless steel pipes comply with GB/T 8162 and GB/T 18248 standards. For detailed specifications, refer to the relevant standards or contact a certified supplier.

35CrMo seamless steel pipes are critical for high-load mechanical components, gas cylinders, and high-pressure systems, offering superior strength and durability.

Used in manufacturing CNG and high-pressure gas cylinders.

Ideal for high-load mechanical components.

Supports high-torque engine components.

Used in high-pressure boiler screws and nuts.

Handles high-pressure, non-corrosive media.

Supports high-load vehicle components.

15crmo seamless boiler tubes, compliant with gb/t ...

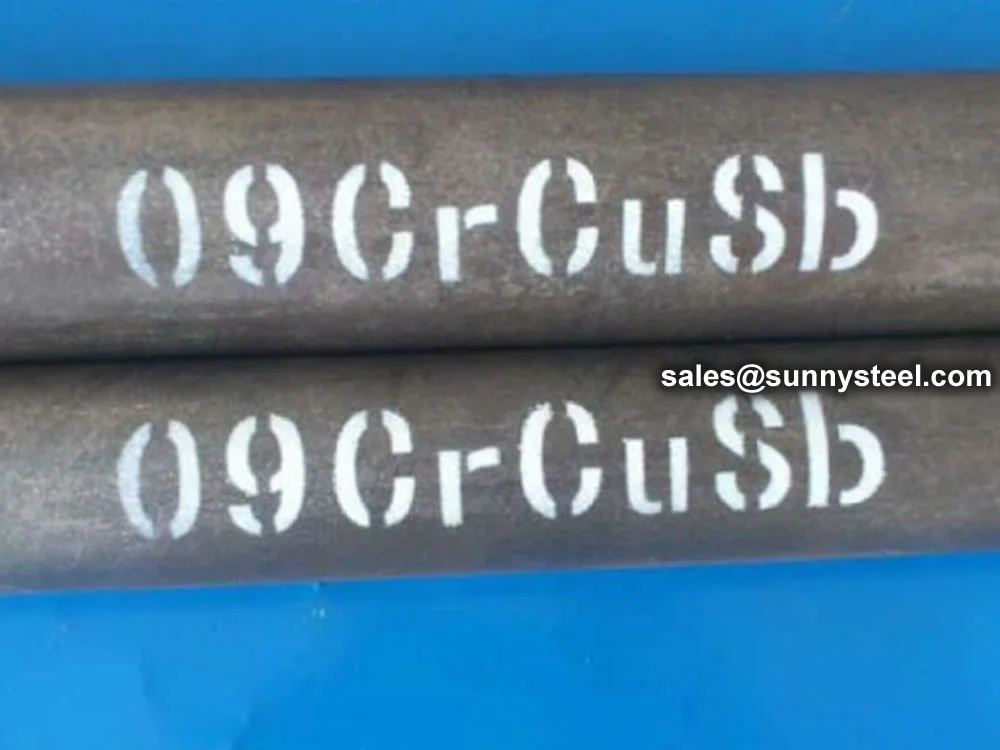

09crcusb seamless steel pipes (nd steel), complian...

12cr5moi seamless steel tubes, compliant with gb/t...

Gb 9948 seamless steel pipes, compliant with gb/t ...

Gb 8163 steel pipes, compliant with gb/t 8163-2018...