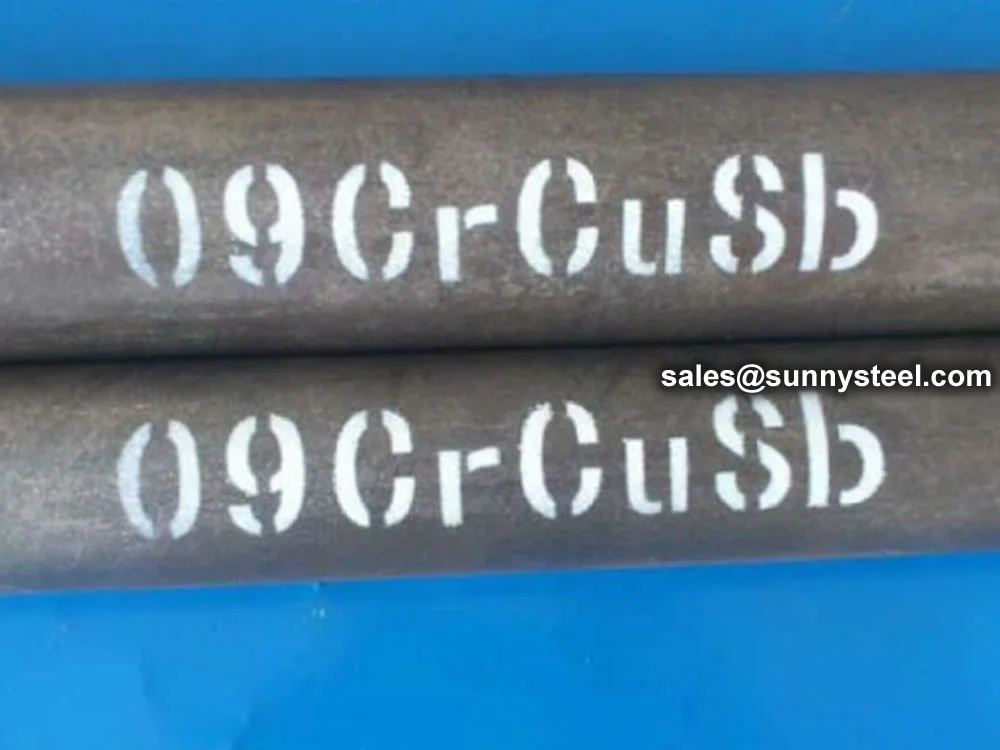

Nd Steel Tubes For Sulfuric Acid Dew Point Corrosion Resistance

09crcusb seamless steel pipes (nd steel), compliant with gb 150.

Nd Steel Tubes For Sulfuric Acid Dew Point Corrosion Resistance

09crcusb seamless steel pipes (nd steel), compliant with gb 150.2-2011, are low-alloy steel tubes designed for superior resistance to sulfuric acid dew point corrosion, ideal for economizers, heat exchangers, and high-sulfur flue gas environments.

09CrCuSb seamless steel pipes, also known as ND steel, are low-alloy steel tubes engineered for exceptional resistance to sulfuric acid dew point corrosion and chloride ion corrosion, compliant with standards like GB 150.2-2011. Developed by the Shanghai Institute of Materials and Xingcheng Special Steel (1987–1990), these pipes are designed for high-sulfur flue gas environments, offering superior corrosion resistance compared to carbon steel and even stainless steel in specific conditions. The alloy’s composition, including chromium (0.70–1.20%), copper (0.25–0.45%), and antimony (0.04–0.10%), forms a dense passivation film during corrosion, enhancing durability in acidic settings.

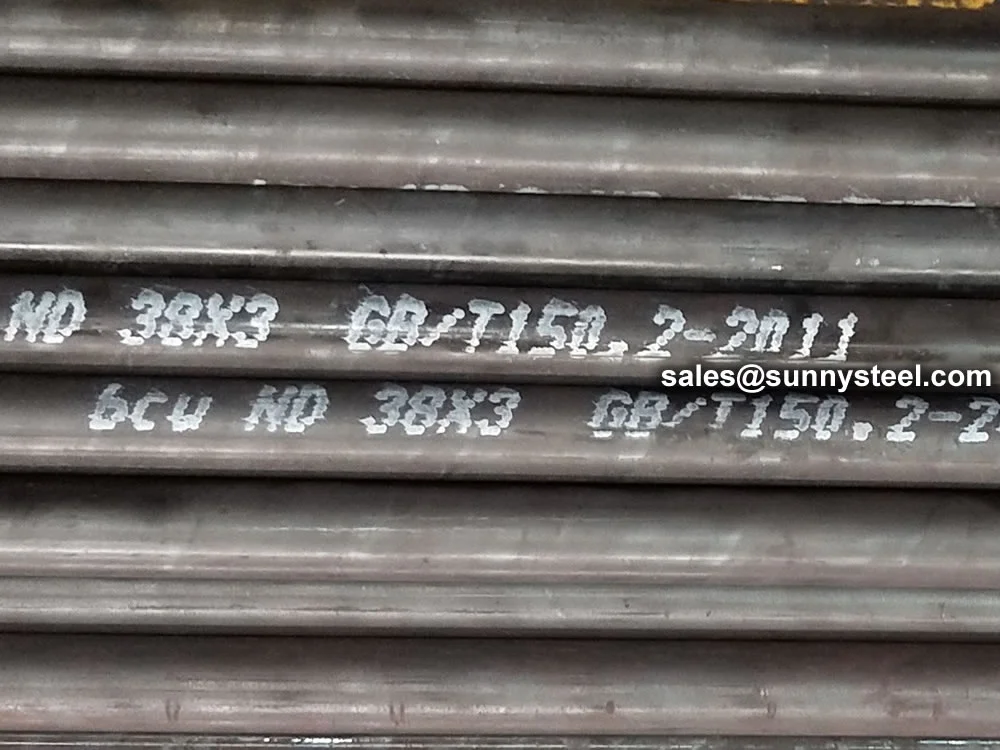

Manufactured through hot-rolling or cold-drawing processes, 09CrCuSb seamless pipes are available in sizes ranging from 1/2 inch to 5 inches (12.7 mm to 127 mm) with wall thicknesses from 0.8 mm to 13 mm, and lengths up to 18 meters or customized per request. Surface treatments such as galvanizing, varnishing, or anti-corrosion coatings ensure long-term performance. These pipes undergo rigorous testing, including hydraulic, ultrasonic, eddy current, and corrosion resistance tests (e.g., 50% H2SO4 at 70°C for 24 hours, corrosion rate ≤80–140 g/m²·h), to meet GB 150.2-2011 standards.

Applications include economizers, air preheaters, heat exchangers, and evaporators in power plants and refineries, where they resist corrosion from sulfur-containing flue gases. Their ability to withstand low-temperature sulfuric acid dew point corrosion (below 200°C) and chloride ion corrosion makes them ideal for harsh industrial environments like petrochemical plants and marine applications. Compared to international standards like ASTM A106 or Corten steel, 09CrCuSb offers unmatched cost-effectiveness, with a market price around 40% of equivalent stainless steel pipes.

09CrCuSb seamless steel pipes are a clean, energy-saving solution, aligning with environmental and efficiency goals. Their excellent weldability (using NDS electrodes without preheating) and mechanical properties make them a preferred choice for engineers designing equipment for high-sulfur, corrosive conditions.

ND steel pipe (09CrCuSb) shall be subject to corrosion resistance test. One sample shall be taken from each batch of two steel pipes, and each sample is a 10 mm long pipe section. Soak in 50% H2SO4 solution at 70 ℃ (± 2 ℃) for 24 hours. The average corrosion rate of two samples shall not be greater than 80g / ㎡ * h or 140g / ㎡ * h, and the specific index shall be indicated in the order.

The carbon equivalent of 09CrCuSb is moderate, the content of S and P is not high, so its welding performance is good, preheating is not necessary during welding, and heat treatment is not required after welding ND steel special NDS electrode is used for welding.

09CrCuSb (ND steel) steel is developed for coal-fired boilers, oil-fired boilers; heat exchangers for electric furnaces, pipes, chimneys, boiler air preheaters, economizers, heat exchangers, condensing coolers, evaporators, etc. Hot-rolled steel sheets and steel pipes with excellent resistance to sulfuric acid dew corrosion. Its superior resistance to sulfuric acid dew point corrosion and very high cost performance is the best material that can completely replace stainless steel and surpass stainless steel (in terms of sulfuric acid dew point corrosion resistance). ND steel has great economic significance, in line with today's high efficiency, longevity and energy saving. "Green" concepts such as environmental protection and national development policy orientation.

ND steel, 09CrCuSb steel, is the most ideal steel for “sulfuric acid resistant low temperature dew point corrosion” at home and abroad. ND steel is widely used in the manufacture of economizers, air preheaters, heat exchangers and in high sulfur flue gas. Equipment such as evaporators, used to resist corrosion of sulfur-containing flue gas dew point. ND steel also has the ability to resist chloride ion corrosion. The main reference index of ND steel pipe (soaked in 50% H2SO4 solution at 70 °C for 24 hours) is higher than that of carbon steel and stainless steel.

Superior resistance to low-temperature sulfuric acid dew point corrosion.

Resists chloride ion corrosion in harsh environments.

40% the cost of comparable stainless steel pipes.

No preheating required with NDS electrodes.

Uniform strength and leak-proof performance.

Ideal for high-sulfur flue gas equipment.

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤0.12 |

| Silicon (Si) | 0.20–0.40 |

| Manganese (Mn) | 0.35–0.65 |

| Phosphorus (P) | ≤0.030 |

| Sulfur (S) | ≤0.020 |

| Chromium (Cr) | 0.70–1.20 |

| Copper (Cu) | 0.25–0.45 |

| Antimony (Sb) | 0.04–0.10 |

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 410–550 |

| Yield Strength (MPa) | ≥245 |

| Elongation, min (%) | ≥25 |

| Impact Energy (J, -40°C) | ≥34 |

| Corrosion Rate (g/m²·h, 50% H2SO4, 70°C) | ≤80–140 |

| Feature | 09CrCuSb (ND Steel) | ASTM A106 Gr. B | Corten Steel |

|---|---|---|---|

| Material Type | Low-Alloy Steel | Carbon Steel | Weathering Steel |

| Corrosion Resistance | High (Sulfuric acid dew point) | Moderate | High (Atmospheric) |

| Temperature Range | Up to 200°C | Up to 400°C | Ambient |

| Tensile Strength (MPa) | 410–550 | ≥415 | 470–630 |

| Yield Strength (MPa) | ≥245 | ≥240 | ≥345 |

| Applications | Economizers, heat exchangers | High-pressure piping | Bridges, structures |

| Key Advantage | Sulfuric acid resistance | High-temperature strength | Weathering resistance |

| C | Si | Mn | P | S | Cr | Cu | Sb |

|---|---|---|---|---|---|---|---|

| ≤0.12 | 0.20~0.40 | 0.35~0.65 | ≤0.030 | ≤0.020 | 0.70~1.10 | 0.25~0.45 | 0.04~0.10 |

| Steel Grade | 09CrCuSb(ND steel) | CRIR(Japan) | 1Cr18Ni9 | Corten | STEN(Japan) | A3(Q235B) |

|---|---|---|---|---|---|---|

| Corrosion Rate | 7.30 | 13.40 | 21.70 | 63.00 | 27.4 | 103.50 |

| Multiple | 1 | 1.84 | 2.97 | 8.63 | 3.75 | 14.11 |

A curated list of long-tail keywords for 09CrCuSb seamless steel pipes, covering specifications, applications, and material properties, presented in a multi-column layout.

Note: 09CrCuSb (ND steel) seamless steel pipes comply with GB 150.2-2011. For detailed specifications, refer to the standard or contact a certified supplier.

09CrCuSb seamless steel pipes are critical for economizers, air preheaters, and heat exchangers in high-sulfur flue gas environments, offering unmatched corrosion resistance.

Recovers waste heat from flue gases in boilers.

Preheats combustion air in high-sulfur environments.

Handles corrosive fluids in industrial settings.

Resists corrosion in high-sulfur flue gas systems.

Handles acidic and corrosive media.

Durable in seawater and corrosive environments.

15crmo seamless boiler tubes, compliant with gb/t ...

35crmo seamless steel pipes, compliant with gb/t 8...

12cr5moi seamless steel tubes, compliant with gb/t...

Gb 9948 seamless steel pipes, compliant with gb/t ...

Gb 8163 steel pipes, compliant with gb/t 8163-2018...