High-strength Alloy Tubes For Petroleum Cracking And High-pressure Applications

12cr5moi seamless steel tubes, compliant with gb/t 9948, are high-strength, low-alloy steel tubes designed for petroleum cracking, offering excellent oxidation resistance and toughness in high-temperature, high-pressure environments.

High-strength Alloy Tubes For Petroleum Cracking And High-pressure Applications

12cr5moi seamless steel tubes, compliant with gb/t 9948, are high-strength, low-alloy steel tubes designed for petroleum cracking, offering excellent oxidation resistance and toughness in high-temperature, high-pressure environments.

12Cr5MoI seamless steel tubes, compliant with GB/T 9948, are low-alloy, high-strength steel tubes designed for petroleum cracking and other high-temperature, high-pressure applications. These tubes are manufactured using a rolling process involving billet inspection, heating, perforation, hot continuous rolling, reheating, sizing, and cooling, ensuring high dimensional accuracy and uniform structure. The complete annealing process reduces hardness, enhances toughness, and improves processability, making them ideal for petrochemical pipe fittings and connecting pipes in petroleum refineries.

Available in outer diameters from 10 mm to 530 mm and wall thicknesses from 2.5 mm to 40 mm, 12Cr5MoI seamless tubes offer excellent oxidation resistance, high-temperature strength, and wear resistance. Surface treatments like varnishing, galvanizing, or anti-corrosion coatings enhance durability. Rigorous testing, including ultrasonic, hydrostatic, and Charpy V-notch impact tests, ensures compliance with GB/T 9948 standards for demanding environments like coal liquefaction projects and chemical processing.

The alloy’s composition, including chromium (4.00–6.00%) and molybdenum (0.40–0.70%), provides superior resistance to corrosion and high-temperature oxidation, making it suitable for applications in petroleum, chemical, power, and aviation industries. Compared to other grades like 15CrMo or ASTM A106, 12Cr5MoI excels in high-temperature environments up to 550°C, offering better plasticity and toughness. Its good weldability and processability allow for versatile forming and machining, though post-weld annealing is recommended to reduce weld seam hardness.

12Cr5MoI seamless steel tubes are a reliable, cost-effective solution for high-pressure, corrosive environments, widely used in boilers, heat exchangers, and pipelines in oil refineries and coal liquefaction systems, ensuring long-term performance and safety.

Resists oxidation in high-temperature environments up to 550°C.

Tensile strength of 440–640 MPa for demanding applications.

Enhanced toughness via complete annealing process.

Good weldability and machinability for versatile forming.

Uniform structure ensures leak-proof performance.

Durable design reduces maintenance costs.

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤0.15 |

| Silicon (Si) | ≤0.50 |

| Manganese (Mn) | 0.30–0.60 |

| Phosphorus (P) | ≤0.025 |

| Sulfur (S) | ≤0.020 |

| Chromium (Cr) | 4.00–6.00 |

| Molybdenum (Mo) | 0.40–0.70 |

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 440–640 |

| Yield Strength (MPa) | ≥235 |

| Elongation, min (%) | ≥21 |

| Impact Energy (J, -20°C) | ≥35 |

| Hardness (HBW, annealed) | ≤200 |

| Feature | 12Cr5MoI (GB/T 9948) | 15CrMo (GB 5310) | ASTM A106 Gr. B |

|---|---|---|---|

| Material Type | Low-Alloy Steel | Low-Alloy Steel | Carbon Steel |

| Temperature Range | Up to 550°C | Up to 550°C | Up to 400°C |

| Tensile Strength (MPa) | 440–640 | 440–640 | ≥415 |

| Yield Strength (MPa) | ≥235 | ≥295 | ≥240 |

| Corrosion Resistance | High | Moderate | Moderate |

| Applications | Petroleum cracking, boilers | Boilers, superheaters | High-pressure piping |

| Key Advantage | High oxidation resistance | Good machinability | Cost-effective |

A curated list of long-tail keywords for 12Cr5MoI seamless steel tubes, covering specifications, applications, and material properties, presented in a multi-column layout.

Note: 12Cr5MoI seamless steel tubes comply with GB/T 9948 standards. For detailed specifications, refer to the standard or contact a certified supplier.

12Cr5MoI seamless steel tubes are critical for petroleum cracking, boilers, and high-pressure systems, offering superior strength and corrosion resistance.

Used in refinery pipe fittings and connecting pipes.

Ideal for high-pressure coal processing systems.

Handles high-temperature steam pipelines.

Resists corrosion in chemical processing.

Durable in corrosive chemical environments.

Used in high-strength aerospace applications.

15crmo seamless boiler tubes, compliant with gb/t ...

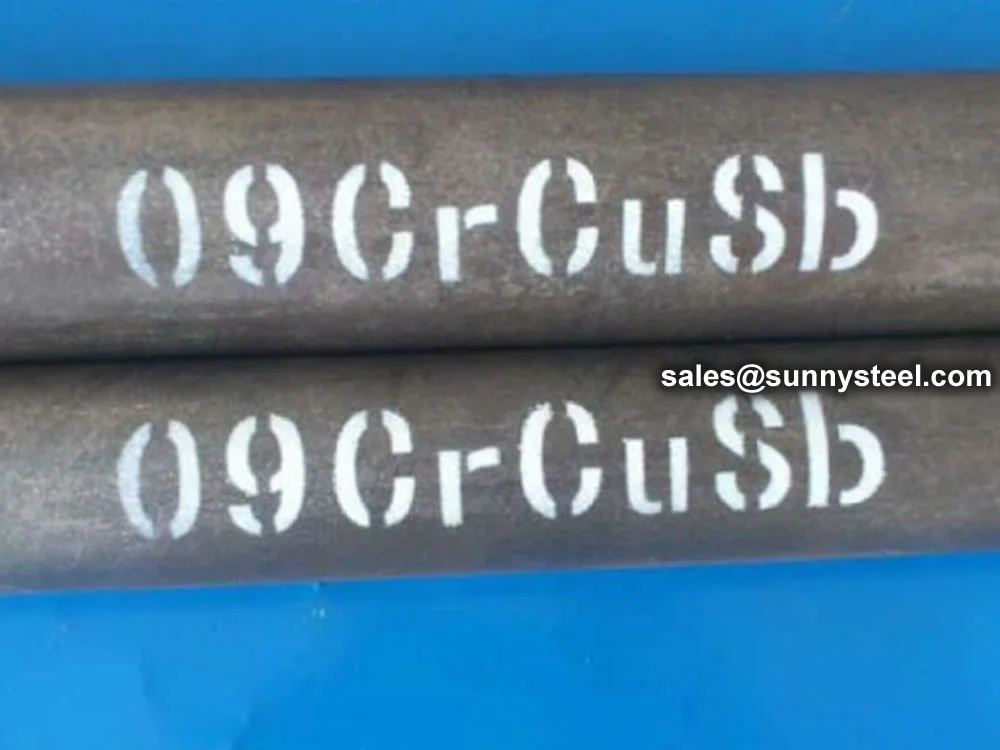

09crcusb seamless steel pipes (nd steel), complian...

35crmo seamless steel pipes, compliant with gb/t 8...

Gb 9948 seamless steel pipes, compliant with gb/t ...

Gb 8163 steel pipes, compliant with gb/t 8163-2018...