High-strength Alloy Tubes For High-pressure Boilers And Petrochemical Applications

15crmo seamless boiler tubes, compliant with gb/t 3077-2015 and gb 5310, are high-strength, low-alloy steel tubes designed for high-pressure boilers, offering excellent thermal strength and oxidation resistance up to 550°c.

High-strength Alloy Tubes For High-pressure Boilers And Petrochemical Applications

15crmo seamless boiler tubes, compliant with gb/t 3077-2015 and gb 5310, are high-strength, low-alloy steel tubes designed for high-pressure boilers, offering excellent thermal strength and oxidation resistance up to 550°c.

15CrMo seamless boiler tubes, compliant with GB/T 3077-2015 and GB 5310, are low-alloy, high-strength steel tubes designed for high-pressure boilers operating at pressures above 9.8 MPa and temperatures between 450°C and 650°C. These tubes are manufactured through seamless processes (hot-finished or cold-finished), ensuring tight dimensional tolerances and excellent surface finish. The production involves electric furnace smelting, continuous casting, or hot rolling, followed by heat treatments like normalizing, quenching, and tempering to enhance mechanical properties, toughness, and hardenability.

Available in outer diameters from 23 mm to 1500 mm and wall thicknesses from 2.8 mm to 150 mm, 15CrMo boiler tubes are ideal for heating surface tubes, headers, economizers, superheaters, and reheaters in high-pressure boiler systems. The alloy’s composition, including chromium (0.80–1.10%) and molybdenum (0.40–0.55%), provides high thermal strength (≥440 MPa) and oxidation resistance at high temperatures, along with resistance to hydrogen corrosion. Surface treatments like varnishing or galvanizing prevent rust, and rigorous testing (hydrostatic, ultrasonic, and flattening tests) ensures compliance with standards.

Compared to other grades like 12CrMo or ASTM A106, 15CrMo offers superior thermal strength and corrosion resistance at 500–550°C, though its toughness is slightly lower. Its weldability is moderate due to higher alloy content, requiring specific welding materials like E5515-B2 electrodes or H15CrMo welding wire. Post-weld heat treatment is recommended to reduce hardness in weld seams. These tubes are widely used in power generation, petrochemical, and chemical industries for applications like steam pipelines, hydrocracking tubes, and synthetic ammonia production.

15CrMo seamless boiler tubes are a reliable choice for high-pressure, high-temperature environments, offering durability, safety, and cost-effectiveness in demanding industrial applications.

15CrMo boiler tube is based on high-quality carbon structural steel, and one or several alloying elements are appropriately added to improve the mechanical properties, toughness and hardenability of steel. Products made of this type of steel usually require heat treatment (normalizing or quenching and tempering); the parts and components made of such steel usually need to undergo quenching and tempering or surface chemical treatment (carburizing, nitriding, etc.), surface Quenching or high-frequency quenching and other treatments. Therefore, according to the chemical composition (mainly carbon content), heat treatment process and use, this type of steel can be roughly divided into three types: carburizing, quenching and tempering and nitriding. Low-alloy heat-resistant steel is stronger than 12CrMo steel, with slightly lower toughness. It has higher heat resistance and oxidation resistance at 500 - 550 °C or lower, along with good mechanical properties, machinability, and cold strain plasticity. The weldability is fair. It is mainly used for the production of seamless steel pipes and sheets of various calibers.

Tensile strength of 440–640 MPa at 500–550°C.

Resists oxidation in high-temperature environments.

Withstands hydrogen-induced corrosion.

Uniform structure for high-pressure reliability.

Moderate weldability with proper heat treatment.

Durable design reduces maintenance costs.

40Cr ≈ 0.40 % C.

12Cr1MoV means 0.9–1.2 % Cr).

20MnVB (V

0.07–0.12 %, B 0.001–0.005 %).

ML30CrMnSi for riveting screws.

| Feature | 15CrMo (GB 5310) | 12CrMo (GB 9948) | ASTM A106 Gr. B |

|---|---|---|---|

| Material Type | Low-Alloy Steel | Low-Alloy Steel | Carbon Steel |

| Temperature Range | 450–650°C | Up to 500°C | Up to 400°C |

| Tensile Strength (MPa) | 440–640 | 410–560 | ≥415 |

| Yield Strength (MPa) | ≥235 | ≥205 | ≥240 |

| Corrosion Resistance | High | Moderate | Moderate |

| Applications | Boilers, superheaters | Petroleum cracking | High-pressure piping |

| Key Advantage | High thermal strength | Good weldability | Cost-effective |

40Cr ≈ 0.40%

carbonCr). If > 1.5%, numbers follow

(e.g., 18Cr2Ni4WA)20MnVB (0.07–0.12%

V, 0.001–0.005% B) ML30CrMnSi for

riveting screws Note: 15CrMo is a low-alloy, heat-resistant steel with superior high-temperature

strength (440–640 MPa) and oxidation resistance up to ~550 °C. It often requires normalization or quenching &

tempering. Alloy grade 15CrMoG, per GB 5310, offers excellent thermal strength and creep resistance in

boilers, headers, superheaters, and steam lines.

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.12–0.18 |

| Silicon (Si) | 0.17–0.37 |

| Manganese (Mn) | 0.40–0.70 |

| Phosphorus (P) | ≤0.035 |

| Sulfur (S) | ≤0.035 |

| Chromium (Cr) | 0.80–1.10 |

| Molybdenum (Mo) | 0.40–0.55 |

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 440–640 |

| Yield Strength (MPa) | ≥235 |

| Elongation, min (%) | ≥21 |

| Impact Energy (J, -20°C) | ≥40 |

| Hardness (HBW, annealed) | ≤229 |

| Process | Temperature (°C) | Coolant |

|---|---|---|

| Hardening | 900 | Air-cooled |

| Tempering | 650 | Air-cooled |

A curated list of long-tail keywords for 15CrMo seamless boiler tubes, covering specifications, applications, and material properties.

Note: 15CrMo seamless boiler tubes comply with GB 5310 and GB/T 3077-2015 standards. For detailed specifications, refer to the standards or contact a certified supplier.

15CrMo seamless boiler tubes are critical for high-pressure boilers, superheaters, and petrochemical systems, offering superior strength and corrosion resistance.

Used in high-pressure steam pipelines and boilers.

Ideal for hydrocracking and heating furnace tubes.

Used in synthetic ammonia and high-sulfur petroleum processing.

Handles high-temperature steam in boiler systems.

Enhances efficiency in heat recovery systems.

Used in high-temperature turbine components.

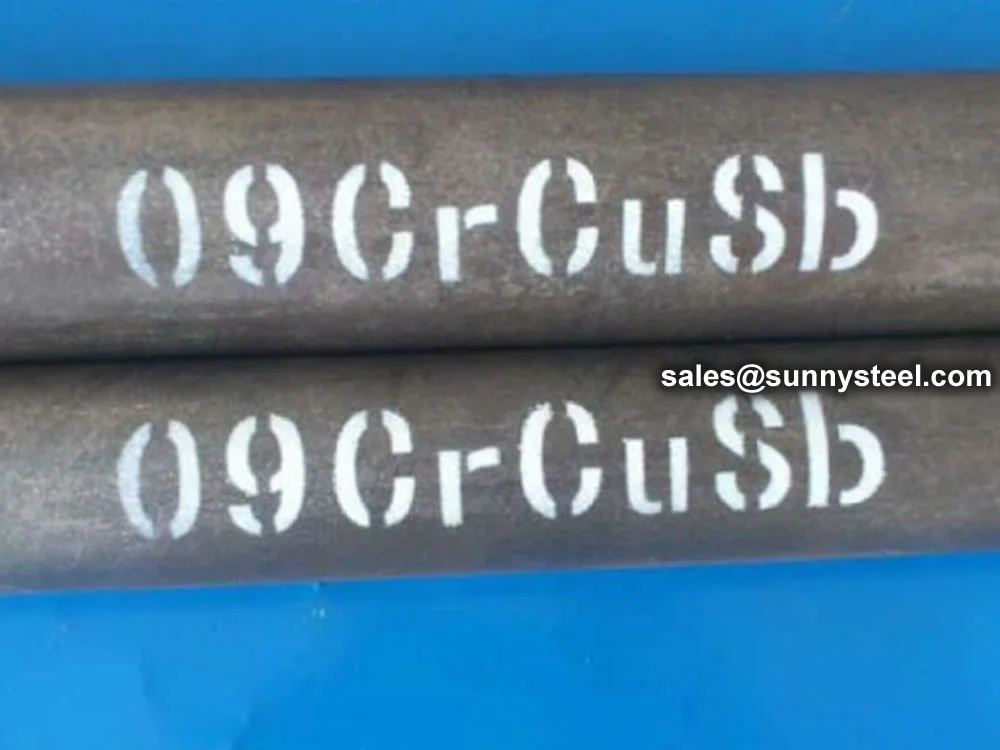

09crcusb seamless steel pipes (nd steel), complian...

35crmo seamless steel pipes, compliant with gb/t 8...

12cr5moi seamless steel tubes, compliant with gb/t...

Gb 9948 seamless steel pipes, compliant with gb/t ...

Gb 8163 steel pipes, compliant with gb/t 8163-2018...