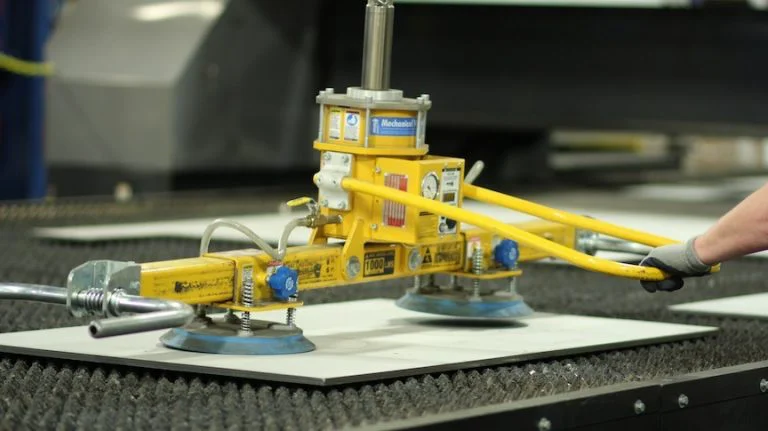

Steel plate

Steel plates are flat structural materials thicker than 6 mm, available in carbon, alloy, stainless, abrasion-resistant and weathering grades—offering strength, corrosion resistance, wear resistance, and suitability for industrial, construction, and pressure vessel use.