Bainite Heat-resistant Steel Tubes For High-pressure Boiler Applications

Gb 5310 12cr2mowvtib seamless boiler tubes, compliant with gb/t 5310-2017, are bainite heat-resistant steel tubes for high-pressure boilers, offering superior high-temperature strength and corrosion resistance for superheaters, reheaters, and petrochemical applications.

Bainite Heat-resistant Steel Tubes For High-pressure Boiler Applications

Gb 5310 12cr2mowvtib seamless boiler tubes, compliant with gb/t 5310-2017, are bainite heat-resistant steel tubes for high-pressure boilers, offering superior high-temperature strength and corrosion resistance for superheaters, reheaters, and petrochemical applications.

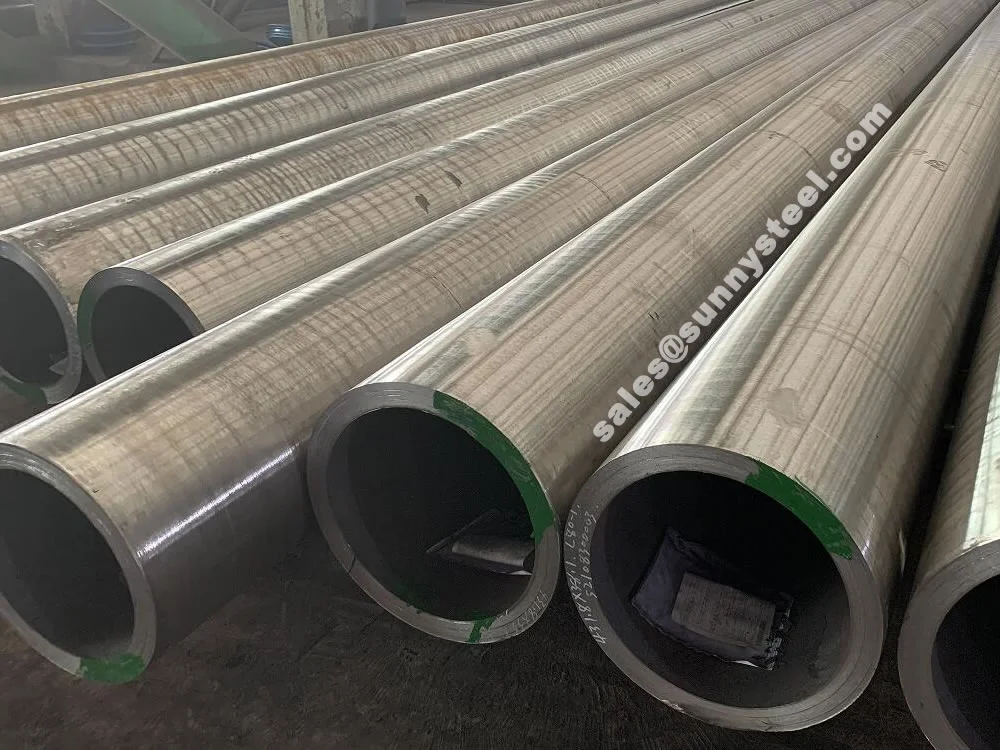

GB 5310 12Cr2MoWVTiB seamless boiler tubes, compliant with GB/T 5310-2017, are multi-element microalloyed low-alloy bainite heat-resistant steel tubes designed for high-pressure boilers operating at pressures ≥9.8 MPa and temperatures between 450°C and 600°C (≤575°C per DL/T 715-2015 for superheaters and reheaters). These tubes are manufactured using seamless processes, either hot-rolled (extrusion, expansion) or cold-drawn (rolling), ensuring high dimensional accuracy and structural integrity.

Available in outer diameters from 23 mm to 1500 mm and wall thicknesses from 2.8 mm to 150 mm, GB 5310 12Cr2MoWVTiB seamless tubes offer exceptional high-temperature strength and creep resistance due to their composition, including chromium (Cr), molybdenum (Mo), tungsten (W), vanadium (V), and titanium (Ti). The steel is smelted via electric furnace, oxygen converter, or electroslag remelting, with tube blanks produced by continuous casting, die casting, or hot rolling (forging). Heat treatment (normalizing and tempering) results in a tempered bainite microstructure, allowing sorbite or tempered martensite but not free ferrite, enhancing mechanical properties. Rigorous testing (hydraulic, flattening, flaring, ultrasonic, low-power, non-metallic inclusions, grain size, microstructure, and decarburization layer) ensures compliance with GB/T 5310-2017 standards.

Developed in China from the late 1960s to the mid-1970s, 12Cr2MoWVTiB steel surpasses similar foreign grades in heat strength and service temperature due to its multi-element microalloying. It is ideal for ultra-supercritical boilers, with good weldability using manual welding (e.g., H12CrMo or H15CrMo welding wire) or automatic welding (e.g., argon arc or submerged arc), though preheating may be required for thicker walls. Surface treatments like varnishing or galvanizing prevent rust, and tubes are delivered with plain, beveled, or threaded ends. These tubes are widely used in power generation, petrochemicals, and industrial boiler systems, ensuring reliable performance under high-pressure and high-temperature conditions.

GB 5310 12Cr2MoWVTiB seamless boiler tubes are a high-performance solution for critical high-pressure boiler systems, offering safety, efficiency, and longevity in demanding industrial environments.

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.08–0.15 |

| Silicon (Si) | 0.45–0.75 |

| Manganese (Mn) | 0.40–0.70 |

| Phosphorus (P) | ≤0.030 |

| Sulfur (S) | ≤0.030 |

| Chromium (Cr) | 1.60–2.10 |

| Molybdenum (Mo) | 0.35–0.50 |

| Tungsten (W) | 0.30–0.55 |

| Vanadium (V) | 0.20–0.30 |

| Titanium (Ti) | 0.04–0.10 |

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 540–690 |

| Yield Strength (MPa) | ≥345 |

| Elongation, min (%) | ≥18 |

| Impact Energy (J, 0°C) | ≥27 |

12Cr2MoWVTiB Seamless Boiler Tubes are engineered for high-pressure and high-temperature environments, specifically for superheater and reheater systems in boiler pipeline protection. Complying with the GB 5310-2008 standard, these seamless alloy tubes are crafted from low-alloy steel with a sophisticated composition including chromium, molybdenum, tungsten, vanadium, titanium, and boron. This ensures exceptional corrosion resistance and high-temperature performance up to 600°C, making them ideal for power generation and petrochemical industries.

The 12Cr2MoWVTiB alloy, also known as G102, was developed in the late 1960s based on Professor Liu Rongzao’s multiple composite strengthening theory. The alloy’s composition enhances creep strength, oxidation resistance, and toughness, making it suitable for demanding industrial piping applications. The tubes are manufactured through forging or hot-rolling at 1150–1200°C, with an end temperature of 850°C, followed by stack cooling to optimize mechanical properties. Their seamless construction ensures uniform strength and precise dimensional accuracy, particularly for small-diameter tubes used in high-pressure boiler systems.

These tubes exhibit excellent weldability, supporting manual arc welding, gas welding, friction welding, TIG, and plasma welding. For manual arc welding, R347 rods are used, while H08Cr2MoVNb or H08CrMoV wires are suitable for gas welding. Preheating to 250–300°C is required for thicknesses over 6mm, followed by post-weld heat treatment (normalizing at 1000–1030°C and tempering at 760–780°C) to ensure weld integrity. The heat treatment process, including normalizing at 1020–1060°C for 30 minutes and tempering at 760–790°C for 3 hours, results in a tempered bainite structure, enhancing durability and resistance to thermal fatigue.

Designed for superheater and reheater pipes with wall temperatures up to 575–600°C (per DL/T 715 standards), 12Cr2MoWVTiB tubes offer superior performance compared to TP347H and TP304H, as demonstrated in 300MW and 600MW subcritical boilers. Available in sizes from 1/2” to 24” (DN15 to DN600), with wall thicknesses from SCH 40 to SCH 160 and customizable lengths up to 12 meters, these tubes undergo rigorous testing (tensile, hardness, flattening, and hydrostatic) to meet GB 5310 standards. Surface treatments like anti-corrosion coatings enhance longevity, while plain or beveled ends facilitate easy installation in industrial piping systems.

The 12Cr2MoWVTiB seamless boiler tubes address challenges like pipeline wear, corrosion, and thermal stress in high-throughput industrial systems. Their ability to resist steam-side oxidation and maintain structural integrity under high temperatures ensures reliable operation in critical applications. These tubes provide a cost-effective, high-performance solution for engineers seeking durable boiler pipeline protection in extreme environments.

Reliably operates up to 600°C in superheater and reheater systems.

Chromium and molybdenum enhance resistance to oxidation and corrosion.

Vanadium and titanium improve long-term durability under stress.

Uniform construction ensures reliability in high-pressure systems.

Outperforms TP347H and TP304H, reducing maintenance costs.

Supports multiple welding methods for versatile installation.

| Feature | GB 5310 12Cr2MoWVTiB | GB 5310 12Cr1MoVG | GB 5310 15CrMoG |

|---|---|---|---|

| Material Type | Bainite Heat-Resistant Steel | Pearlitic Alloy Steel | Pearlitic Alloy Steel |

| Temperature Range | ≤575°C (superheater) | ≤580°C (superheater) | ≤540°C (superheater) |

| Tensile Strength (MPa) | 540–690 | 470–640 | 440–640 |

| Yield Strength (MPa) | ≥345 | ≥255 | ≥295 |

| Weldability | Good (preheating may be required) | Good | Moderate |

| Applications | Ultra-supercritical boilers, petrochemicals | High-pressure boilers | Ultra-supercritical boilers |

| Key Advantage | Superior heat strength | High endurance strength | High thermal strength |

A curated list of long-tail keywords for GB 5310 12Cr2MoWVTiB seamless boiler tubes, covering specifications, applications, and material properties.

Note: GB 5310 12Cr2MoWVTiB seamless boiler tubes comply with GB/T 5310-2017 standards. For detailed specifications, refer to the standards or contact a certified supplier.

GB 5310 12Cr2MoWVTiB seamless boiler tubes are critical for high-pressure and high-temperature systems in power generation, petrochemicals, and manufacturing, offering superior heat strength and corrosion resistance at pressures ≥9.8 MPa and temperatures up to 575°C–600°C.[](https://www.sunnysteel.com/gb-5310-12cr2mowvtib-high-pressure-seamless-boiler-tubes.php)

Handles pressures ≥9.8 MPa for efficient power generation.

Operates reliably up to 575°C for optimal steam production.

Enhances thermal efficiency in high-pressure boiler systems.

Ensures safe high-pressure steam flow up to 600°C.

Supports high-pressure petrochemical processes.

Facilitates efficient heat transfer in industrial systems.

Gb 5310 20mng seamless boiler tubes, compliant wit...

Gb 5310 25mng seamless boiler tubes, compliant wit...

Gb 5310 12cr2mog seamless boiler tubes, compliant ...