JIS Seamless Pipes

Japanese Industrial Standard Steel

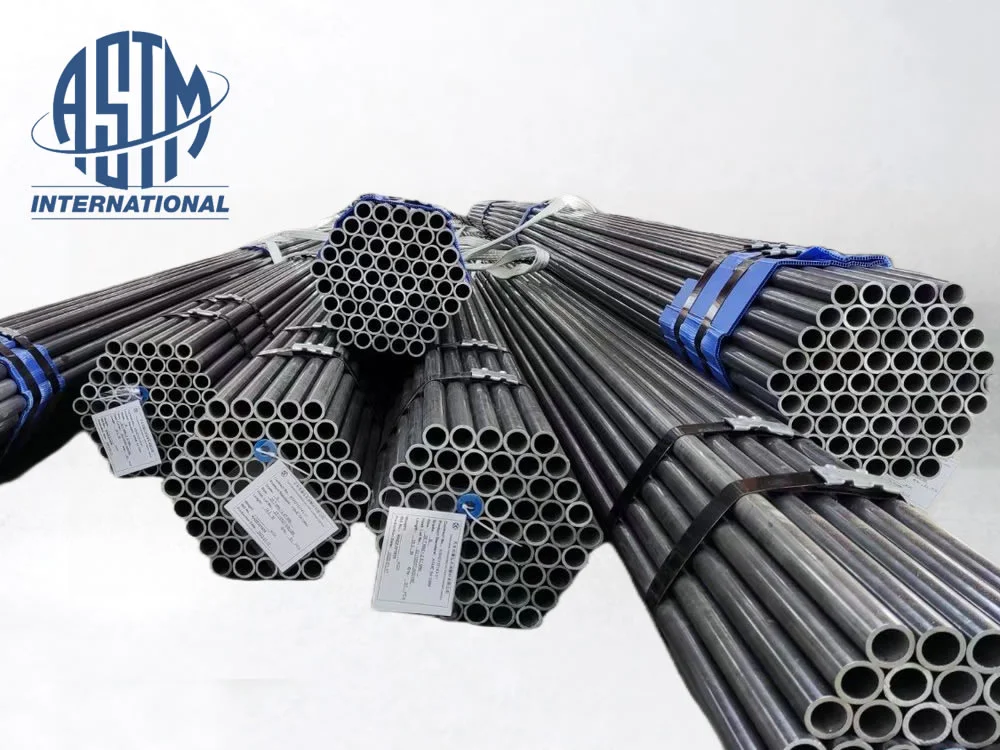

Jis seamless pipes, compliant with japanese industrial standards (jis), are high-quality steel pipes for high-pressure boilers, petrochemical pipelines, oil and gas wells, structural components, automotive parts, and power generation systems, offering excellent strength, corrosion resistance, and durability.