High-strength Tubes For Efficient Heat Transfer

Jis g3461 carbon steel tubes offer superior strength and corrosion resistance for boiler and heat exchanger systems, ensuring efficient heat transfer up to 350°c.

High-strength Tubes For Efficient Heat Transfer

Jis g3461 carbon steel tubes offer superior strength and corrosion resistance for boiler and heat exchanger systems, ensuring efficient heat transfer up to 350°c.

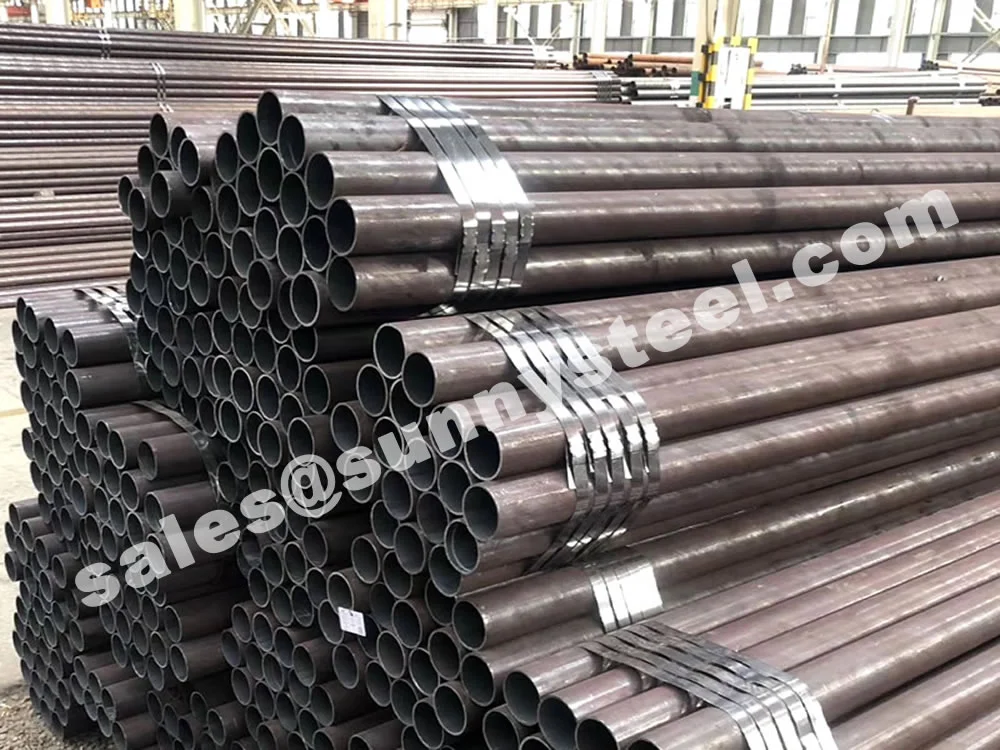

JIS G3461 Carbon Steel Tubes are seamless or electric resistance welded tubes designed for boiler pipeline protection and heat exchanger applications, offering exceptional corrosion resistance and durability. Compliant with the JIS G3461 standard, these carbon steel boiler tubes are engineered with grades STB 340, STB 410, and STB 510, making them ideal for high-temperature systems in power plants, chemical industries, and petrochemical facilities.

Manufactured through hot-rolling, cold-drawing, or electric resistance welding, JIS G3461 Carbon Steel Tubes undergo heat treatments like normalizing or annealing to achieve optimal mechanical properties. The tubes’ composition, with controlled carbon (≤0.32%) and manganese (0.30–1.00%), ensures high strength and ductility, while optional coatings like 3LPE or FBE enhance corrosion resistance for harsh environments. Available in sizes from 15.9 mm to 139.8 mm OD, with wall thicknesses from 1.2 mm to 12.7 mm, and lengths up to 12 meters, these tubes meet diverse project needs.

JIS G3461 Carbon Steel Tubes are rigorously tested for tensile strength, flattening, flaring, and hydrostatic performance to ensure compliance with JIS standards. With a minimum tensile strength of 340 MPa (STB 340) to 510 MPa (STB 510), they offer reliable performance in heat exchanger tubes and boiler systems operating up to 350°C. Their corrosion resistance makes them suitable for handling steam, water, and corrosive fluids in applications like superheaters, air preheaters, and condenser tubes.

Compared to other standards like ASTM A192, JIS G3461 Carbon Steel Tubes are optimized for boiler and heat exchanger applications, offering a balance of cost-effectiveness and performance. Their seamless or welded construction supports bending and flanging, with recommended preheating (100–150°C) and post-weld heat treatment (600–650°C) to ensure weld integrity. These tubes are also used in catalyzer tubes for chemical processing, providing durability in corrosive environments.

JIS G3461 Carbon Steel Tubes address critical challenges like pipeline wear, thermal stress, and corrosion in high-temperature industrial systems. Their robust design and corrosion resistance make them a preferred choice for engineers seeking reliable boiler tubes and heat exchanger tubes for demanding applications, ensuring safety, efficiency, and longevity.

Optional coatings protect against corrosion in harsh boiler environments.

Optimized for efficient heat exchange in boilers and condensers.

Ideal for superheaters, air preheaters, and catalyzer tubes.

Supports welding and flanging for flexible installation.

Durable design reduces maintenance and replacement costs.

STB 410 and STB 510 grades ensure robust performance.

| Feature | JIS G3461 STB 410 | ASTM A192 | DIN 17175 St 45.8 |

|---|---|---|---|

| Material Type | Carbon Steel | Carbon Steel | Carbon Steel |

| Temperature Range | Up to 350°C | Up to 538°C | Up to 450°C |

| Corrosion Resistance | Good (With coatings) | Moderate | Moderate |

| Applications | Boilers, Heat Exchangers | High-Pressure Boilers | Boilers, Heat Exchangers |

| Tensile Strength (MPa) | 410 (min) | 325 (min) | 410–530 |

| Yield Strength (MPa) | 245 (min) | 180 (min) | 255 (min) |

| Key Advantage | Cost-effective heat transfer | High-pressure performance | Balanced strength and durability |

| Element | STB 340 (%) | STB 410 (%) | STB 510 (%) |

|---|---|---|---|

| Carbon (C) | ≤0.18 | ≤0.32 | ≤0.30 |

| Manganese (Mn) | 0.30–0.60 | 0.30–0.80 | 0.30–1.00 |

| Phosphorus (P) | ≤0.035 | ≤0.035 | ≤0.035 |

| Sulfur (S) | ≤0.035 | ≤0.035 | ≤0.035 |

| Silicon (Si) | ≤0.35 | ≤0.35 | 0.10–0.35 |

| Property | STB 340 | STB 410 | STB 510 |

|---|---|---|---|

| Tensile Strength, min (MPa) | 340 | 410 | 510 |

| Yield Strength, min (MPa) | 175 | 245 | 295 |

| Elongation, min (%) | 35 (Longitudinal) | 30 (Longitudinal) | 25 (Longitudinal) |

| Hardness, max (HBW) | 143 | 163 | 183 |

| JIS G3461 | ASTM | ASME | BS | DIN | ISO | ABS | NK | LRS | DNV |

|---|---|---|---|---|---|---|---|---|---|

| STB 340 | A178 | SA178 A | 3059-P1 320 | 17175 st 35.8 | — | ABS D | KSTB 33 | Sec 6 320 | Sec 4-E-TS360 |

| STB 410 | A178 C | SA178 C | 3059-P2 440 | 17175 st 45.8 | — | ABS F | KSTB 42 | Sec 6 410 | Sec 4-E-TS410-1 |

| STB 510 | — | — | — | 17175 19Mn 5 | — | — | — | — | Sec 4-E-TS510 |

The tubes shall be practically straight. and the two ends shall be at right angles to the axis of the tube. The tubes shall be free from defects detrimental to practical use.

| Symbol of Class | Heat Treatment | ||||

|---|---|---|---|---|---|

| Hot finished seamless steel tube | Cold finished seamless steel tube | Electric resistance welded steel tube (other than hot/cold finished) | Finished electric resistance welded steel tube | Fold finished electric resistance welded steel tube | |

| STB340 | As manufactured, as required, low temperature annealing or normalizing may be performed. | Low temperature annealing, normalizing or full annealing. | Normalizing | As manufactured. However, as required, low temperature annealing or normalizing may be performed. | Normalizing |

| STB 410 | As manufactured. However, as required, low temperature annealing or normalizing may be performed. | Low temperature annealing, normalizing or full annealing. | Normalizing | Low temperature annealing | |

| STB 510 | Normalizing | ||||

We also offer steel fabrication service where steel plates can go through processings like cutting, welding, bending, machining, pre-coating, pre-lined, beveling, or as you require. Our steel mills have fabricating employees that have 5-10 years of working experience. If you are interested in buying JIS G3461 steel tube products, contact us now for the latest price or check the following table for equivalent steel grade of JIS G3461.

| Tolerances | Division of wall thickness (mm) | Division of method of manufacture | Hot finished seamless steel tube | Cold finished seamless steel tube | Electric resistance welded steel tube | |||

|---|---|---|---|---|---|---|---|---|

| Division of outside diameter (mm) | Under 100 | 100 or over | Under 40 | 40 or over | Under 40 | 40 or over | ||

| Tolerances on wall thickness % | Under 2 | --- | --- | +0.4mm 0 |

+22 0 |

+0.3 0 |

+18 0 |

|

| 2 or over to and excl. 2.4 | +40 0 |

--- | +20 0 |

+18 0 |

||||

| 2.4 or over to or excl. 3.8 | +35 0 |

+35 0 |

||||||

| 3.8 or over to or excl. 4.6 | +33 0 |

+33 0 |

||||||

| 4.6 or over | +28 0 |

+28 0 |

||||||

| Tolerances on thickness disparity% | --- | Within 22.8 of wall thickness | --- | --- | ||||

Explore JIS G3461 carbon steel tubes with targeted long-tail keywords, covering specifications, applications, grades, manufacturing, procurement, and dimensions for boiler and heat exchanger systems.

Note: JIS G3461 covers seamless and welded carbon steel tubes for boiler and heat exchanger applications up to 350°C. For detailed specifications, refer to the JIS G3461 standard or contact a certified supplier.

JIS G3461 Carbon Steel Tubes are widely used in industries requiring excellent heat transfer and corrosion-resistant performance in boiler and heat exchanger systems.

Handles temperatures up to 350°C for efficient steam production.

Supports high-temperature steam for enhanced boiler efficiency.

Improves combustion efficiency in boiler systems.

Enables efficient cooling in heat exchanger systems.

Resists corrosion for safe chemical processing.

Reliable for heat exchangers and turbines.

Jis g3455 carbon steel pipes, designed for high-pr...

Jis g3101 ss400 steel pipes for structural applica...

Jis g3454 stpg38 seamless pipes for pressure servi...

Jis g3458 alloy steel pipes, designed for high-tem...

Jis g3462 alloy steel tubes are designed for high-...

Jis g3429 seamless tubes for high-pressure gas cyl...