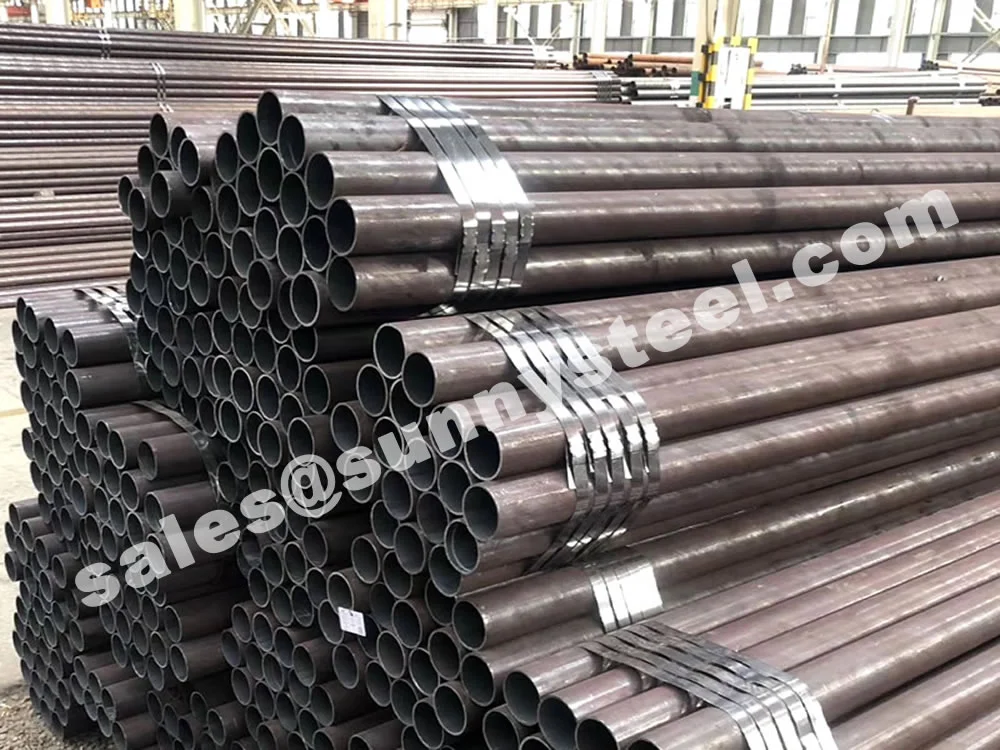

Seamless And Welded Tubes For Automotive And Mechanical Applications

Jis g3445 carbon steel tubes for machine structural purposes, offering high strength and formability, ideal for automotive, machinery, and furniture.

Seamless And Welded Tubes For Automotive And Mechanical Applications

Jis g3445 carbon steel tubes for machine structural purposes, offering high strength and formability, ideal for automotive, machinery, and furniture. available in grades stkm11a to stkm20a, these seamless and welded tubes excel in precision engineering.

JIS G3445 Carbon Steel Tubes are engineered for machine structural purposes, delivering exceptional strength, formability, and precision. These tubes are widely used in automotive steel tubes and precision mechanical tubes, conforming to the Japanese Industrial Standard (JIS). They are ideal for machinery, automobiles, bicycles, furniture, appliances, and other mechanical components. Available in grades ranging from STKM11A to STKM20A, they offer excellent corrosion resistance and durability.

These tubes are manufactured using seamless, electric resistance welding (ERW), or butt welding processes, with outer diameters from 19.05 mm to 260 mm and wall thicknesses from 2 mm to 26 mm. Lengths are available in single random, double random, or customized options up to 10 meters. They can be hot-rolled, cold-drawn, or cold-finished, with heat treatments like normalizing, annealing, or stress relieving to enhance mechanical properties. The low carbon content (e.g., 0.12% max for STKM11A) ensures excellent formability for bending, flaring, and shaping.

With a controlled chemical composition (carbon, silicon, manganese, phosphorus, and sulfur), these tubes offer high weldability and moderate corrosion resistance. For example, STKM13C, with up to 0.25% carbon, provides a tensile strength of 510 MPa minimum, compared to 290 MPa for STKM11A. Rigorous testing—tensile, flattening, bending, and nondestructive (ultrasonic or eddy current)—ensures compliance with JIS G3445 standards. Surface finishes include black painted, varnished, or galvanized options, with beveled or straight ends.

Applications include automotive manufacturing (e.g., drive shafts, steering columns), machinery (e.g., hydraulic cylinders), and furniture (e.g., chair frames). Their precision and resistance to pipeline wear make them suitable for dynamic systems. Compared to JIS G3444 or ASTM A519, JIS G3445 excels in formability and tolerances, making it a top choice for precision engineering.

These tubes tackle mechanical stress, deformation, and corrosion challenges, offering a cost-effective, robust solution for industries needing reliable machine structural parts that ensure performance, safety, and longevity.

Low carbon content ensures easy bending, flaring, and shaping without deformation.

High tensile strength supports demanding structural and mechanical applications.

Tight tolerances and smooth finishes ensure high precision in manufacturing.

Suitable for automotive, machinery, furniture, and hydraulic systems.

Low-cost material with high durability reduces overall project costs.

Certified with rigorous testing to meet JIS G3445 standards.

| Grade | C (% max) | Si (% max) | Mn (% max) | P (% max) | S (% max) |

|---|---|---|---|---|---|

| STKM 11A | 0.12 | 0.35 | 0.60 | 0.040 | 0.040 |

| STKM 12A | 0.20 | 0.35 | 0.60 | 0.040 | 0.040 |

| STKM 13A | 0.25 | 0.35 | 0.30-0.90 | 0.040 | 0.040 |

| STKM 13C | 0.25 | 0.35 | 0.30-0.90 | 0.040 | 0.040 |

| Grade | Tensile Strength (MPa min) | Yield Strength (MPa min) | Elongation (% min) |

|---|---|---|---|

| STKM 11A | 290 | - | 35 |

| STKM 12A | 340 | 175 | 35 |

| STKM 13A | 375 | 215 | 30 |

| STKM 13C | 510 | 380 | 20 |

| Feature | JIS G3445 | ASTM A519 | DIN 2391 |

|---|---|---|---|

| Material Type | Carbon Steel | Carbon/Alloy Steel | Carbon Steel |

| Temperature Range | Ambient to moderate | Ambient to moderate | Ambient to moderate |

| Tensile Strength (MPa) | ≥290 (STKM11A), ≥510 (STKM13C) | ≥345 (Grade 1010), ≥655 (Grade 1045) | ≥340 (St35) |

| Yield Strength (MPa) | ≥175 (STKM12A), ≥380 (STKM13C) | ≥275 (Grade 1010), ≥450 (Grade 1045) | ≥235 (St35) |

| Corrosion Resistance | Moderate (with coatings) | Moderate (with coatings) | Moderate (with coatings) |

| Dimensional Tolerances | OD: ±0.12–0.18 mm, WT: ±10% | OD: ±1%, WT: ±10% | OD: ±0.08–0.15 mm, WT: ±10% |

| Fabrication Options | Bending, flaring, welding | Bending, flaring, welding | Bending, flaring, welding |

| Applications | Automotive, machinery, furniture | Mechanical tubing, hydraulic systems | Precision tubing, hydraulic systems |

| Key Advantage | High formability | Wide range of grades | High precision |

| High-Temperature Suitability | Not suitable | Not suitable | Not suitable |

| NUMBER | GRADE | NUMBER | GRADE | NUMBER | GRADE | NUMBER | GRADE | |

|---|---|---|---|---|---|---|---|---|

| D 3517 | Grade 11 A | STKM 11 A | A513 | MT1010 | G-3445 | STKM11A | – | – |

| A519 | MT1010 | |||||||

| Grade 12A | STKM 12 A | A513 | MT1015 | STKM12A | 980 | CDS-3 | ||

| A519 | MT1015 | |||||||

| Grade 12 B | STKM 12 B | – | – | STKM12B | – | – | ||

| Grade 12C | STKM 12C | A512 | MT1015 | STKM12C | – | – | ||

| A513 | ||||||||

| Grade 13 A | STKM 13 A | A512 | MT 1025 | STKM13A | – | – | ||

| A513 | MTX1025 | |||||||

| A519 | MT 1025 | |||||||

| Grade13B | STKM 13 B | – | – | STKM13B | 980 | CDS-4 | ||

| Grade13 C | STKM 13 C | – | – | STKM13C | – | – | ||

| Grade14 A | STKM 14 A | A513 | MT1030 | STKM14A | 1717 | CDS-103 | ||

| A519 | MT1030 | |||||||

| Grade14 B | STKM 14 B | – | – | STKM14B | – | – | ||

| Grade14 C | STKM 14 C | – | – | STKM14C | – | – | ||

| Grade15 A | STKM 15 A | A513 | MT1033 | STKM15A | 1717 | CDS-105 | ||

| Grade15 C | STKM 15 C | – | – | STKM15C | – | – | ||

| Grade16 A | STKM 16 A | A519 | MT1040 | STKM16A | 980 | CDS-5 | ||

| Grade16 C | STKM 16 C | – | – | STKM16C | – | – | ||

| Grade17 A | STKM 17 A | A519 | MT1050 | STKM17A | 980 | CDS-7 | ||

| 1717 | CDS-107 | |||||||

| Grade17 C | STKM 17 C | – | – | STKM17B | – | – | ||

| Grade18 A | STKM 18 A | A519 | MT1524 | STKM18A | 980 | CDS-9 | ||

| Grade18 B | STKM 18 B | – | – | STKM18B | – | – | ||

| Grade18 C | STKM 18 C | – | – | STKM18C | – | – | ||

| Grade19 A | STKM 19 A | – | – | – | – | – | ||

| Grade19 C | STKM 19 C | – | – | – | – | – | ||

| Grade20 A | STKM 20 A | – | – | – | – | – | ||

Explore JIS G3445 carbon steel tubes with targeted long-tail keywords, covering specifications, applications, grades, manufacturing, procurement, and dimensions for machine structural purposes.

Note: JIS G3445 covers seamless and welded carbon steel tubes for machine structural purposes. For detailed specifications, refer to the JIS G3445 standard or contact a certified supplier.

JIS G3445 Carbon Steel Tubes are engineered for machine structural purposes, excelling in automotive, machinery, furniture, and hydraulic system applications.

Used in drive shafts, steering columns, and shock absorbers.

Ideal for hydraulic cylinders and mechanical frameworks.

Forms durable frames for chairs and tables.

Provides lightweight and strong structural support.

Used in high-precision hydraulic and pneumatic lines.

Supports structural components in household appliances.

Jis g3455 carbon steel pipes, designed for high-pr...

Jis g3101 ss400 steel pipes for structural applica...

Jis g3454 stpg38 seamless pipes for pressure servi...

Jis g3458 alloy steel pipes, designed for high-tem...

Jis g3461 carbon steel tubes offer superior streng...

Jis g3462 alloy steel tubes are designed for high-...