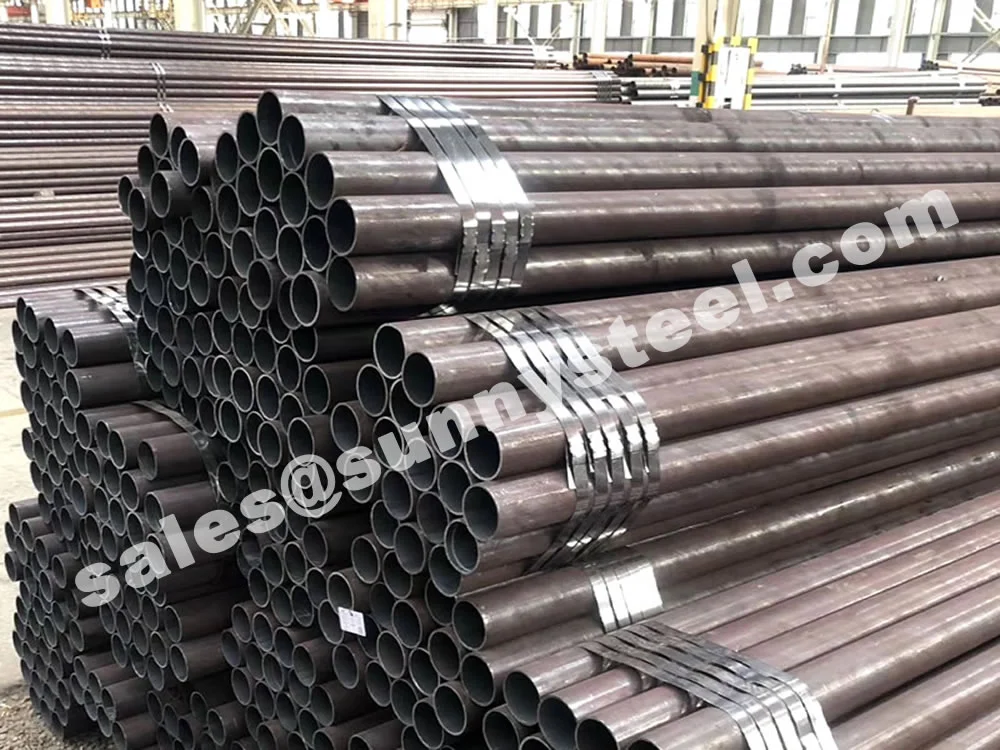

High-strength Carbon Steel Pipes For Boilers And Pipelines

Jis g3454 stpg38 seamless pipes for pressure service up to 350°c, offering high strength and corrosion resistance.

High-strength Carbon Steel Pipes For Boilers And Pipelines

Jis g3454 stpg38 seamless pipes for pressure service up to 350°c, offering high strength and corrosion resistance. ideal for boilers, pipelines, and industrial piping systems in power generation and petrochemicals.

JIS G3454 STPG38 Seamless Pipes are engineered for pressure service at temperatures up to 350°C, offering superior strength, durability, and corrosion resistance. Conforming to the Japanese Industrial Standard (JIS G3454), these seamless carbon steel pipes are ideal for boiler pipeline protection and industrial piping solutions in industries such as power generation, petrochemicals, and construction. The STPG38 grade provides a balance of strength and formability, making it suitable for high-pressure applications.

Manufactured using seamless processes (hot-finished or cold-finished), JIS G3454 STPG38 Seamless Pipes are available in outer diameters from 10.5 mm to 660.4 mm and wall thicknesses from 1.8 mm to 60 mm. Lengths can be fixed (6m, 9m, 12m) or customized (5-12m) to meet project requirements. The seamless construction ensures uniform wall thickness and eliminates weld-related weaknesses, providing reliability under high-pressure conditions. Heat treatments such as normalizing or stress relieving enhance mechanical properties, ensuring performance in demanding environments.

The chemical composition of STPG38, with controlled carbon (≤0.25%), silicon (≤0.35%), manganese (0.30–0.90%), phosphorus (≤0.040%), and sulfur (≤0.040%), ensures good weldability and moderate corrosion resistance. These pipes undergo rigorous testing, including tensile, flattening, bending, hydrostatic, and nondestructive examinations, to comply with JIS G3454 standards. Surface treatments like galvanizing, varnishing, or 3LPE coatings enhance durability, while plain or beveled ends facilitate easy installation.

JIS G3454 STPG38 Seamless Pipes are widely used in high-pressure steam boilers, pipelines for oil, gas, and water, and industrial systems requiring robust performance. Compared to JIS G3455 (higher pressure) or JIS G3452 (general piping), STPG38 offers a cost-effective solution for moderate-pressure, high-temperature applications. Its seamless design and high strength make it ideal for pressure service piping in refineries and power plants.

These pipes address challenges like pipeline wear, pressure surges, and thermal stress in industrial systems. Their robust construction, combined with JIS G3454 compliance, makes them a reliable choice for engineers seeking durable industrial piping solutions for high-pressure environments, ensuring safety, efficiency, and longevity.

| Grade | C (% max) | Si (% max) | Mn (%) | P (% max) | S (% max) |

|---|---|---|---|---|---|

| STPG38 | 0.25 | 0.35 | 0.30-0.90 | 0.040 | 0.040 |

| Grade | Tensile Strength (MPa min) | Yield Strength (MPa min) | Elongation (% min) |

|---|---|---|---|

| STPG38 | 370 | 215 | 30 |

| Feature | JIS G3454 STPG38 | ASTM A106 Grade A | DIN 1629 St37.0 |

|---|---|---|---|

| Material Type | Carbon Steel | Carbon Steel | Carbon Steel |

| Temperature Range | Up to 350°C | Up to 400°C | Up to 300°C |

| Tensile Strength (MPa) | ≥370 | ≥330 | ≥350 |

| Yield Strength (MPa) | ≥215 | ≥205 | ≥235 |

| Corrosion Resistance | Moderate (with coatings) | Moderate (with coatings) | Moderate |

| Dimensional Tolerances | OD: ±0.5–1%, WT: ±10–12.5% | OD: ±1%, WT: ±12.5% | OD: ±1%, WT: ±12.5% |

| Fabrication Options | Welding, bending, flanging | Welding, bending, flanging | Welding, bending |

| Applications | Boilers, pipelines, power plants | Boilers, pipelines, refineries | Mechanical engineering, vessels |

| Key Advantage | Cost-effective for moderate pressure | Higher temperature resistance | Cost-effective for structural use |

| Low-Temperature Suitability | Not suitable | Not suitable | Not suitable |

Designed to withstand high-pressure conditions in boilers and pipelines.

Maintains integrity at temperatures up to 350°C, ideal for steam systems.

Seamless construction ensures uniform strength and leak-proof performance.

Good weldability supports easy fabrication and system integration.

Durable design reduces maintenance and replacement costs.

Certified with rigorous testing to meet JIS G3454 standards.

Major JIS Standards

JIS Standards Since

Processing Capabilities

Quality Compliance

Manufactured in strict accordance with JIS standards, guaranteeing consistent quality, performance, and safety.

Known for excellent surface finish, precise dimensions, and tight tolerances crucial for high-performance applications.

Available in carbon steel, alloy steel, and stainless steel to suit various temperature and pressure requirements.

Designed to withstand demanding conditions, offering excellent mechanical properties including tensile strength and toughness.

Widely utilized in power generation, oil and gas, automotive, construction, and general manufacturing industries.

Undergo comprehensive testing including non-destructive testing and hydrostatic testing with full certification.

Several JIS (Japanese Industrial Standards) standards are commonly referenced for steel pipes, each specifying requirements for different types of pipes used in various applications.

Commonly used in general piping for pressure applications, offering reliable performance under pressure conditions.

Ideal for applications requiring resistance to elevated temperatures, ensuring performance in high-temperature environments.

Specifically designed for heat transfer applications in boilers and heat exchangers, optimized for thermal efficiency.

Offering enhanced strength and wear resistance for demanding mechanical applications and structural components.

Another standard for heat transfer applications, providing reliable performance in boiler and heat exchanger systems.

For more demanding heat transfer environments requiring enhanced material properties and corrosion resistance.

High-quality steel billets are carefully selected based on required chemical composition and mechanical properties.

A solid round billet is heated and pierced to create a hollow shell, typically using a rotary piercing mill.

The hollow shell is rolled (hot or cold) or drawn through dies to achieve desired outer diameter, wall thickness, and length.

Pipes undergo various heat treatments such as normalizing, annealing, or quenching and tempering to achieve specific properties.

Including straightening, cutting to precise lengths, and end finishing such as beveling or threading.

Rigorous inspection and testing including visual inspection, dimensional checks, non-destructive testing, and mechanical property tests.

JIS seamless pipes, compliant with standards like JIS G3454, G3455, G3456, and G3445, are critical for high-pressure and high-temperature systems in power generation, petrochemicals, oil and gas, construction, automotive, and manufacturing, offering superior strength, corrosion resistance, and durability up to 350°C.

Handles temperatures up to 350°C for efficient steam production.

Resists corrosion for safe fluid transport.

Durable casing and tubing for drilling operations.

High strength for construction and engineering.

Employed in vehicle components requiring high strength and precision, such as chassis parts and hydraulic systems.

Integrated into machinery, hydraulic cylinders, and equipment where seamless high-quality tubing is required.

Jis g3455 carbon steel pipes, designed for high-pr...

Jis g3101 ss400 steel pipes for structural applica...

Jis g3458 alloy steel pipes, designed for high-tem...

Jis g3461 carbon steel tubes offer superior streng...

Jis g3462 alloy steel tubes are designed for high-...

Jis g3429 seamless tubes for high-pressure gas cyl...