Seamless Pipes by Applications are engineered for demanding industrial environments, offering superior strength, durability, and corrosion resistance. Manufactured without welds, these pipes ensure uniform structure and reliability under high-pressure and high-temperature conditions, making them ideal for oil and gas piping, boiler tubes, petrochemical piping, and construction piping. Seamless pipes are used across industries like power generation, petrochemicals, oil and gas, and infrastructure for their leak-proof performance and longevity.

Seamless Pipes are produced through hot-rolling or cold-drawing processes, with outer diameters ranging from 6 mm to 914 mm and wall thicknesses from 1 mm to 100 mm. Lengths are available in standard (6m, 12m) or customized options (up to 18m) to meet project specifications. Heat treatments like normalizing, quenching, or tempering enhance mechanical properties, ensuring performance in extreme conditions. The absence of welds eliminates weak points, making these pipes suitable for high-pressure piping applications where safety and reliability are critical.

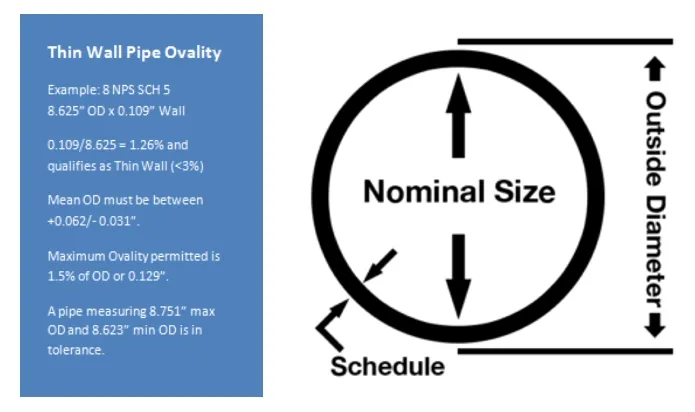

The chemical composition of seamless pipes varies by grade (e.g., carbon steel, alloy steel, or stainless steel), typically including carbon (0.08–0.30%), silicon (0.10–0.50%), manganese (0.30–1.50%), phosphorus (≤0.040%), and sulfur (≤0.040%), with alloying elements like chromium or molybdenum for enhanced corrosion resistance. Rigorous testing, including tensile, hydrostatic, flattening, and nondestructive tests (ultrasonic or eddy current), ensures compliance with standards like ASTM, JIS, or DIN. Surface treatments such as galvanizing, 3LPE, or epoxy coatings protect against pipeline wear, while plain, beveled, or threaded ends facilitate installation.

Seamless pipes excel in applications requiring high-pressure resistance, such as oil and gas pipelines, boiler systems, heat exchangers, and structural frameworks. Compared to welded pipes, seamless pipes offer superior strength and uniformity, making them the preferred choice for critical applications in refineries, power plants, and construction projects. Their versatility supports diverse industries, from transporting corrosive fluids to supporting heavy structural loads.

These pipes address challenges like high-pressure containment, corrosion, and thermal stress in industrial systems. Their seamless construction and compliance with international standards make them a reliable choice for engineers seeking durable industrial piping solutions, ensuring safety, efficiency, and extended service life in demanding environments.

Key Benefits

High-Pressure Resistance

Withstands extreme pressures in oil and gas, boiler, and petrochemical systems.

Thermal Stability

Performs reliably at high temperatures, ideal for boiler tubes.

Corrosion Resistance

Resists corrosion with coatings, suitable for harsh environments.

Seamless Durability

Uniform structure eliminates weld defects for leak-proof performance.

Cost-Effective

Long-lasting materials reduce maintenance and replacement costs.

Quality Assurance

Certified with rigorous testing to meet industry standards.