Seamless Tubes For High-pressure Boiler Waterwalls

Seamless waterwall tubes for boiler waterwall panels, offering high-pressure resistance and corrosion protection for power generation and industrial boilers.

Seamless Tubes For High-pressure Boiler Waterwalls

Seamless waterwall tubes for boiler waterwall panels, offering high-pressure resistance and corrosion protection for power generation and industrial boilers.

Waterwall Tubes are seamless steel tubes designed for use in boiler waterwall panels, providing exceptional high-pressure resistance and corrosion protection. Conforming to standards like ASTM A192, ASTM A210, and EN 10216-2, these tubes are critical for power plant boiler tubes and industrial boiler tubes in power generation and industrial heating systems. Their seamless construction ensures durability and reliability in high-temperature and high-pressure environments up to 600°C and 25 MPa.

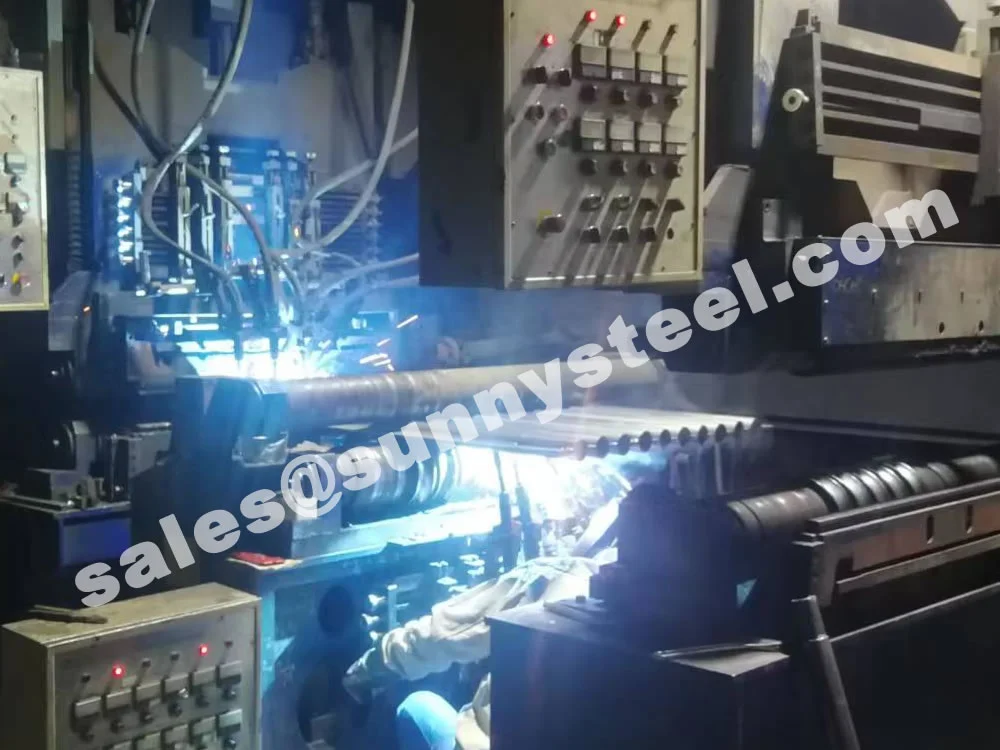

Manufactured through hot-rolling or cold-drawing processes, Seamless Waterwall Tubes are available in outer diameters from 25.4 mm to 76.2 mm and wall thicknesses from 3 mm to 12 mm. Standard lengths (6m, 12m) or customized lengths (up to 24m) meet diverse project requirements. Heat treatments such as normalizing or stress-relieving enhance mechanical properties, ensuring resistance to pipeline wear and thermal stress. The seamless design eliminates weld imperfections, making these tubes ideal for waterwall panels that absorb heat from combustion gases.

The chemical composition of waterwall tubes typically includes carbon (0.06–0.35%), silicon (0.10–0.50%), manganese (0.29–1.06%), phosphorus (≤0.035%), and sulfur (≤0.035%), with grades like ASTM A210 A1 or C offering balanced strength and corrosion resistance. Rigorous testing, including tensile, hardness, flattening, flaring, and hydrostatic tests, ensures compliance with industry standards. Surface treatments like phosphating, black oxide, or external coatings (e.g., 3LPE) protect against corrosion, while plain or beveled ends facilitate welding or installation in waterwall assemblies.

Waterwall Tubes are essential for boiler systems in coal-fired, biomass, or gas-fired power plants, where they form waterwall panels to contain high-pressure water or steam while absorbing radiant heat. Compared to other boiler tubes, waterwall tubes are optimized for heat transfer efficiency and structural integrity under cyclic thermal loads. Their ability to resist oxidation, scaling, and erosion ensures reliable performance in harsh combustion environments.

These tubes address challenges like high-pressure containment, corrosion, and thermal fatigue in boiler waterwalls. Their seamless construction, adherence to stringent standards, and robust material properties make them a dependable choice for engineers seeking durable high-pressure boiler piping solutions, ensuring safety, efficiency, and prolonged service life in demanding boiler applications.

Withstands pressures up to 25 MPa in waterwall panels.

Optimizes heat absorption at temperatures up to 600°C.

Resists scaling and oxidation with coatings and material properties.

Eliminates weld imperfections for reliable performance.

Minimizes maintenance with durable construction.

Certified with rigorous testing to meet ASTM and EN standards.

Other structural pipes provide high strength and v...

Steel pipe for gas cylinder offers high-strength, ...

Seamless pipes for high-temperature applications o...