Seamless and Welded Steel Tubes for Efficient Heat Transfer

Seamless heat exchange tubes for efficient heat transfer, offering corrosion resistance and durability for power, petrochemical, and hvac applications.

Heat Exchange Tubes are seamless steel tubes designed for efficient heat transfer in heat exchangers, offering exceptional corrosion resistance and durability. Conforming to standards like ASTM A179, ASTM A213, and EN 10216-2, these tubes are ideal for power plant heat exchangers, petrochemical heat transfer, and HVAC systems. Their seamless construction ensures reliable performance under high-pressure conditions up to 25 MPa and temperatures up to 600°C.

Manufactured through cold-drawing or hot-rolling processes, Seamless Heat Exchanger Tubes are available in outer diameters from 6.35 mm to 101.6 mm and wall thicknesses from 0.5 mm to 7.0 mm. Standard lengths (6m, 12m) or customized lengths (up to 24m) meet diverse project requirements. Heat treatments such as annealing or normalizing enhance mechanical properties, ensuring resistance to pipeline wear and thermal fatigue. The seamless design eliminates weld imperfections, critical for maintaining heat transfer efficiency.

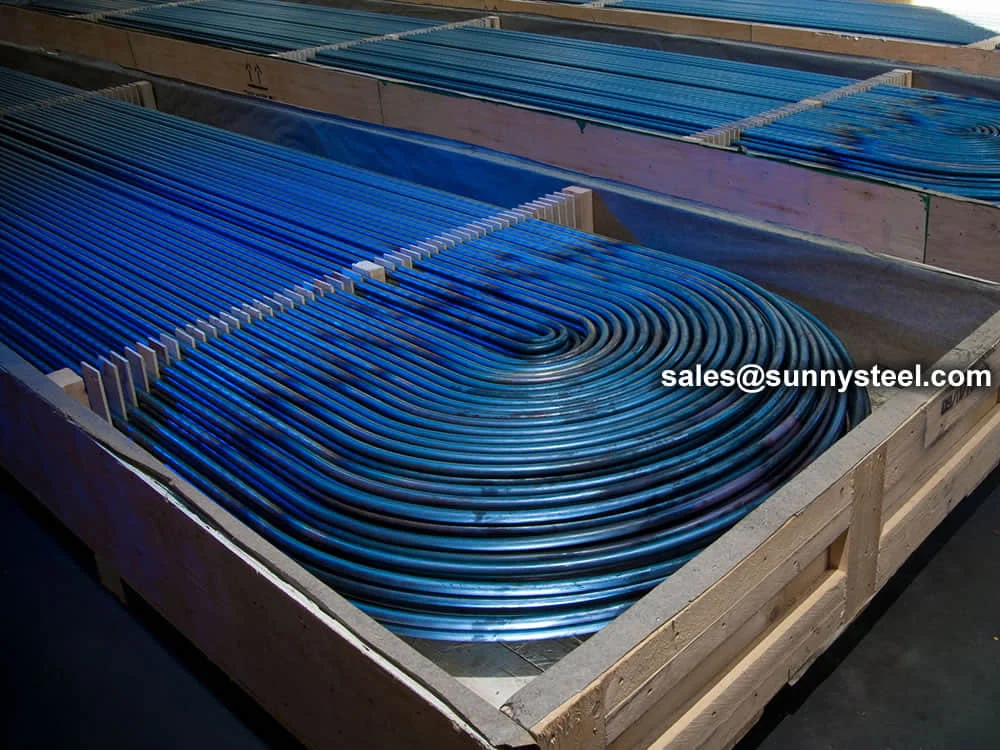

The chemical composition of heat exchange tubes typically includes carbon (0.06–0.18%), manganese (0.27–0.63%), phosphorus (≤0.035%), sulfur (≤0.035%), and silicon (0.10–0.35%), with grades like ASTM A179 or A213 T11 offering excellent corrosion resistance and thermal conductivity. Rigorous testing, including tensile, hardness, flattening, flaring, and hydrostatic tests, ensures compliance with industry standards. Surface treatments like phosphating, passivation, or external coatings (e.g., 3LPE) protect against corrosion, while U-bend or straight configurations facilitate installation in heat exchanger assemblies.

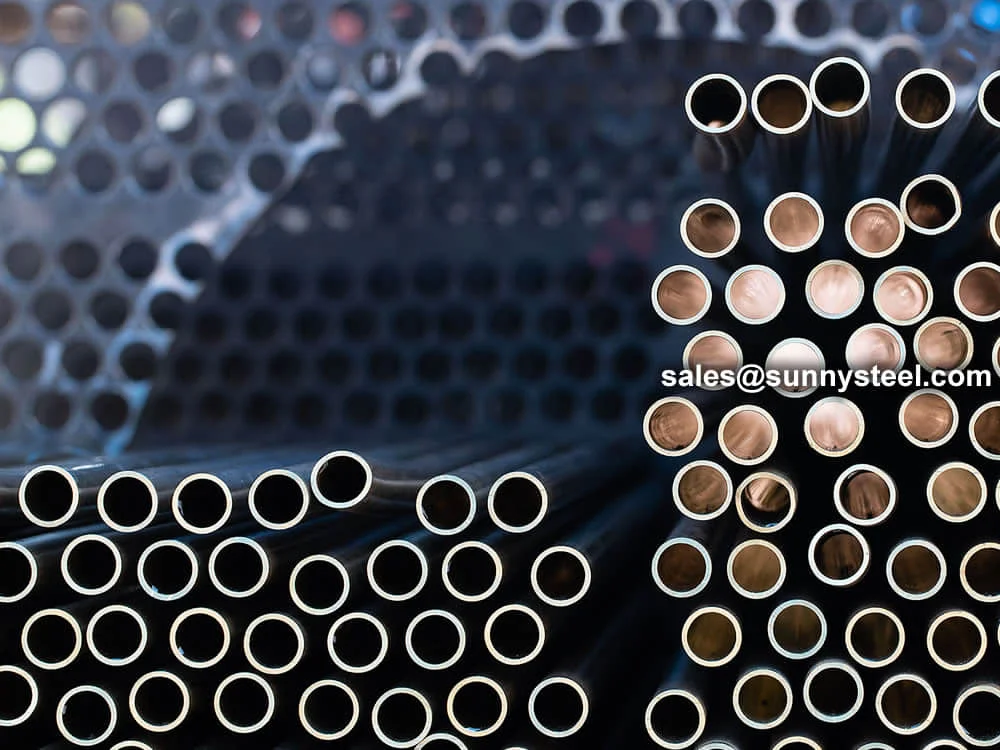

Heat Exchange Tubes are essential for shell-and-tube heat exchangers, condensers, and evaporators in power plants, refineries, and HVAC systems. Compared to welded tubes, seamless heat exchange tubes offer superior thermal conductivity and pressure resistance, making them suitable for transferring heat in corrosive environments like cooling water or chemical fluids. Their ability to resist scaling, oxidation, and thermal stress ensures reliable performance in demanding applications.

These tubes address challenges like heat transfer efficiency, corrosion, and mechanical stress in heat exchanger systems. Their seamless construction, adherence to stringent standards, and robust material properties make them a dependable choice for engineers seeking durable seamless heat exchanger tubes solutions, ensuring safety, efficiency, and prolonged service life in heat transfer applications.

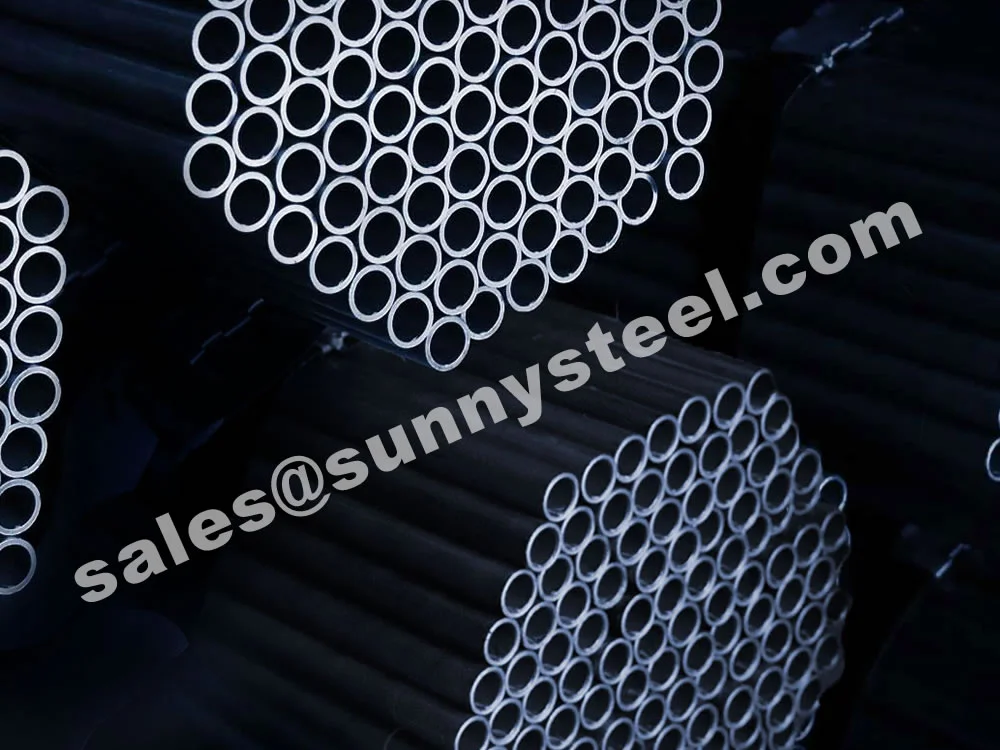

Heat Exchanger Tubes bundle

Exchanger & condensers

Types of

The heat exchange tube is one of the elements of the heat exchanger, which is placed in the cylinder and used for heat exchange between the two media.

Has high thermal conductivity and good isothermal properties. It is a device that can quickly transfer heat energy from one point to another with almost no heat loss, so it is called a heat transfer superconductor, and its thermal conductivity is thousands of times that of copper.

ASTM A556 Superheater Steel Tube Heat Exchanger

SUNNY STEEL

Alloy steel pipes, made from high-quality carbon steel, alloy structural steel, and stainless heat-resisting steel, offer superior performance where carbon steel tubes are limited.

Containing elements like nickel, chromium, molybdenum, and vanadium, these tubes provide enhanced corrosion resistance, high-temperature tolerance (up to 600°C), and strength for demanding applications. Available as seamless or welded tubes (e.g., ASTM A335 Gr P1, P5, P9, P11 for pipes; ASTM A234 WP5, WP9, WP11 for fittings), they are 100% recyclable, environmentally friendly, and energy-saving, aligning with national strategies to expand high-pressure alloy pipe applications. Their lightweight design, economic advantages, and ability to handle diverse fluids make them a preferred choice for heat exchanger systems in chemical, petrochemical, and power generation industries.

| Grade | C (%) | Si (%) | Mn (%) | P (% max) | S (% max) |

|---|---|---|---|---|---|

| ASTM A179 | 0.06–0.18 | - | 0.27–0.63 | 0.035 | 0.035 |

| ASTM A213 T11 | 0.05–0.15 | 0.50–1.00 | 0.30–0.60 | 0.025 | 0.025 |

| EN 10216-2 P235GH | 0.16 max | 0.35 max | 1.20 max | 0.025 | 0.020 |

Material: Commonly used materials are carbon steel, low alloy steel, stainless steel, copper, copper-nickel alloy, aluminum alloy, titanium, etc. In addition, there are some non-metallic materials, such as graphite, ceramics, polytetrafluoroethylene, etc. In the design, appropriate materials should be selected according to the working pressure, temperature and corrosiveness of the medium.

| Grade | Tensile Strength (MPa min) | Yield Strength (MPa min) | Elongation (% min) |

|---|---|---|---|

| ASTM A179 | 325 | 180 | 35 |

| ASTM A213 T11 | 415 | 205 | 30 |

| EN 10216-2 P235GH | 360–500 | 235 | 25 |

| Feature | Heat Exchange Tubes | Fluid Tubes | Superheater Tubes |

|---|---|---|---|

| Material Type | Carbon/Low-Alloy Steel | Carbon Steel | Carbon/Alloy Steel |

| Temperature Range | Up to 600°C | -40°C to 450°C | Up to 500°C |

| Tensile Strength (MPa) | 325–500 | 360–500 | 325–480 |

| Yield Strength (MPa) | 180–235 | 235–240 | 180–280 |

| Corrosion Resistance | High (with coatings) | Moderate (with coatings) | Moderate (with coatings) |

| Pressure Resistance | High (up to 25 MPa) | High (up to 30 MPa) | Moderate (up to 20 MPa) |

| Cost | Moderate | Moderate | Moderate |

| Applications | Heat exchangers, condensers | Fluid transport (oil, gas) | Superheaters, feedwater heaters |

| Key Advantage | High thermal conductivity | High-pressure fluid reliability | Thermal conductivity in boilers |

| Manufacturing Process | Seamless, heat-treated | Seamless, heat-treated | Seamless, cold-drawn |

Explore seamless heat exchange tubes with targeted long-tail keywords, covering specifications, applications, manufacturing, procurement, and dimensions for heat exchanger systems.

Note: Heat exchange tubes are designed for efficient heat transfer in demanding applications. For detailed specifications, refer to ASTM A179, A213, EN 10216-2, or contact a certified supplier.

Heat Exchange Tubes are vital for efficient heat transfer in power generation, petrochemical, and HVAC systems, ensuring optimal performance and durability.

Transfers heat in condensers and feedwater heaters.

Manages heat in chemical processing systems.

Facilitates heat transfer in heating and cooling units.

Handles corrosive fluids in heat exchangers.

Supports cooling systems in marine applications.

Recovers heat in industrial processes.

Other structural pipes provide high strength and v...

Steel pipe for gas cylinder offers high-strength, ...

Seamless pipes for high-temperature applications o...