High-precision Seamless Tubes For Machinery And Structural Use

Mechanical tubes offer high precision and strength for industrial applications, including machinery, automotive, and structural systems.

High-precision Seamless Tubes For Machinery And Structural Use

Mechanical tubes offer high precision and strength for industrial applications, including machinery, automotive, and structural systems.

Mechanical Tubes are seamless or welded steel tubes engineered for precision steel tubes applications in machinery, automotive, and structural systems. Conforming to standards such as ASTM A519, DIN 2391, and EN 10305-1, these tubes offer exceptional high strength and dimensional accuracy, making them ideal for demanding industrial environments, including construction equipment, automotive components, and heavy machinery.

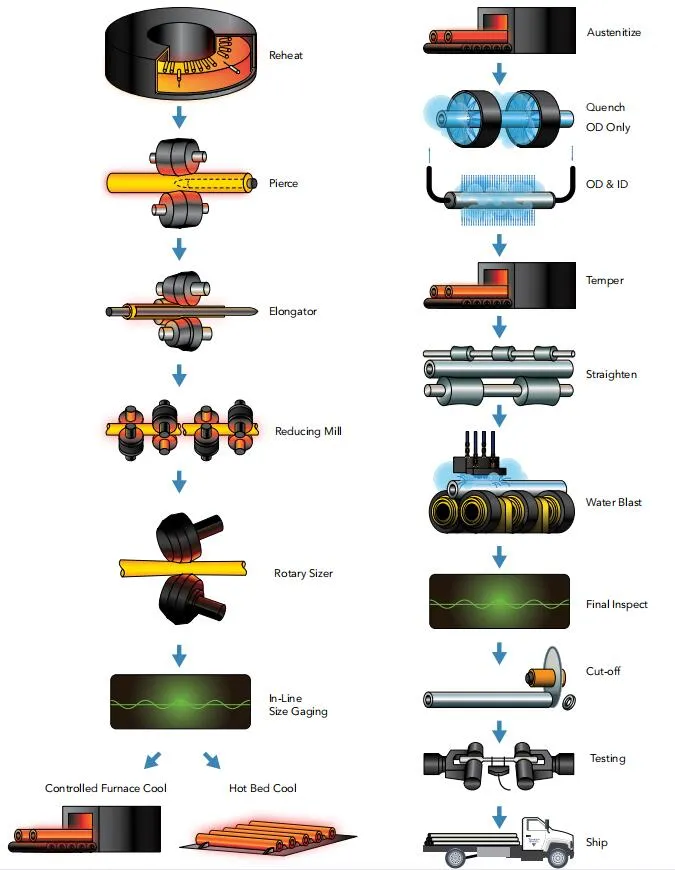

Manufactured through cold-drawing, hot-rolling, or welding processes, Seamless Mechanical Tubes achieve tight tolerances (H8–H10) and smooth surface finishes (Ra ≤ 0.8 µm), ensuring compatibility with precision components. Available in outer diameters from 6 mm to 406 mm and wall thicknesses from 0.5 mm to 40 mm, they are designed to withstand high mechanical stress and resist pipeline wear. Materials like carbon steel (AISI 1020, 1045), alloy steel (AISI 4140), and stainless steel (304, 316) are selected for their strength and durability, with optional coatings like zinc or phosphate for enhanced corrosion resistance.

Mechanical Tubes address challenges like mechanical stress, fatigue, and dimensional inconsistencies in industrial applications. Their robust construction and versatility make them a preferred choice for engineers seeking reliable industrial tubing solutions for high-performance systems.

Mechanical tubes

Mechanical tubes are engineered to meet stringent requirements for industrial applications:

These specifications ensure mechanical tubes meet the demands of precision machinery and structural applications, providing durability and reliability.

Tight tolerances (H8–H10) ensure compatibility with precision components.

Withstands high mechanical stress and fatigue in demanding applications.

Ra ≤ 0.8 µm reduces friction and enhances component compatibility.

Available in seamless and welded forms for diverse applications.

Durable design reduces maintenance and replacement costs.

Available in various diameters and lengths up to 12 m.

Unlike standard pipes, which primarily transport fluids, mechanical tubing is produced to meet specific performance requirements like strength, dimensional accuracy, and surface finish.

| Abbr. | Corresponding | Application |

|---|---|---|

| A511 | ASTM A511 / A511M | Specification for Seamless Stainless Steel Mechanical Tubing |

| A512 | ASTM A512 / ASME SA512 | Specification for Cold-Drawn Buttweld Carbon Steel Mechanical Tubing |

| A513 | ASTM A513 / A513M | Specification for Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing |

| A519 | ASTM A519 / A519M | Specification for Seamless Carbon and Alloy Steel Mechanical Tubing |

| A554 | ASTM A554 | Specification for Welded Stainless Steel Mechanical Tubing |

| OD Size Range (Inches, Inclusive) | Wall Percent of OD | OD (Inches) | ID (Inches) | Quenched & Tempered OD & ID (± Inches) | OD Size Range (mm, Inclusive) | Wall Percent of OD | OD (mm) | ID (mm) | Quenched & Tempered OD & ID (± mm) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Over | Under | Over | Under | Over | Under | Over | Under | ||||||

| 0.500-1.699 1.700-2.099 2.100-2.499 |

All All All |

.005 .006 .007 |

.000 .000 .000 |

.000 .000 .000 |

.005 .006 .007 |

.015 .020 .023 |

12.70-43.16 43.17-53.32 53.33-63.48 |

All All All |

0.13 0.15 0.18 |

0.00 0.00 0.00 |

0.00 0.00 0.00 |

0.13 0.15 0.18 |

0.38 0.51 0.58 |

| 2.500-2.899 2.900-3.299 3.300-3.699 3.700-4.099 |

All All All All |

.008 .009 .010 .011 |

.000 .000 .000 .000 |

.000 .000 .000 .000 |

.008 .009 .010 .011 |

.025 .028 .030 .033 |

63.49-73.64 73.65-83.80 83.81-93.96 93.97-104.12 |

All All All All |

0.20 0.23 0.25 0.28 |

0.00 0.00 0.00 0.00 |

0.00 0.00 0.00 0.00 |

0.20 0.23 0.25 0.28 |

0.64 0.71 0.76 0.84 |

| 4.100-4.499 4.500-4.899 4.900-5.299 5.300-5.549 |

All All All All |

.012 .013 .014 .015 |

.000 .000 .000 .000 |

.000 .000 .000 .000 |

.012 .013 .014 .015 |

.036 .038 .041 .044 |

104.13-114.28 114.29-124.44 124.45-134.60 134.61-140.95 |

All All All All |

0.30 0.33 0.36 0.38 |

0.00 0.00 0.00 0.00 |

0.00 0.00 0.00 0.00 |

0.30 0.33 0.36 0.38 |

0.91 0.97 1.04 1.12 |

| 5.550-5.999 | Under 6 6 to 7½ Over 7½ |

.010 .009 .018 |

.010 .009 .000 |

.010 .009 .009 |

.010 .009 .009 |

.047 .047 .047 |

140.96-152.38 | Under 6 6 to 7½ Over 7½ |

0.25 0.23 0.46 |

0.25 0.23 0.00 |

0.25 0.23 0.23 |

0.25 0.23 0.23 |

1.19 1.19 1.19 |

| 6.000-6.499 | Under 6 6 to 7½ Over 7½ |

.013 .010 .020 |

.013 .010 .000 |

.013 .010 .010 |

.013 .010 .010 |

.050 .050 .050 |

152.39-165.08 | Under 6 6 to 7½ Over 7½ |

0.33 0.25 0.51 |

0.33 0.25 0.00 |

0.33 0.25 0.25 |

0.33 0.25 0.25 |

1.27 1.27 1.27 |

| 6.500-6.999 | Under 6 6 to 7½ Over 7½ |

.015 .012 .023 |

.015 .012 .000 |

.015 .012 .012 |

.015 .012 .012 |

.057 .053 .053 |

165.09-177.78 | Under 6 6 to 7½ Over 7½ |

0.38 0.30 0.58 |

0.38 0.30 0.00 |

0.38 0.30 0.30 |

0.38 0.36 0.30 |

1.45 1.35 1.35 |

| 7.000-7.499 | Under 6 6 to 7½ Over 7½ |

.018 .013 .026 |

.018 .013 .000 |

.018 .013 .013 |

.018 .013 .013 |

.065 .056 .056 |

177.79-190.48 | Under 6 6 to 7½ Over 7½ |

0.46 0.33 0.66 |

0.46 0.33 0.00 |

0.46 0.33 0.33 |

0.46 0.33 0.33 |

1.65 1.42 1.42 |

| 7.500-8.000 | Under 6 6 to 7½ Over 7½ |

.020 .015 .030 |

.020 .015 .000 |

.020 .015 .015 |

.020 .015 .015 |

.070 .060 .060 |

190.49-203.20 | Under 6 6 to 7½ Over 7½ |

0.51 0.38 0.76 |

0.51 0.38 0.00 |

0.51 0.38 0.38 |

0.51 0.38 0.38 |

1.78 1.52 1.52 |

Seamless mechanical tubing is furnished in both cold-drawn and hotfinished form in a wide range of sizes, from 1.375" to 7.750" OD and from 0.188" to 1.625" wall thickness, as shown on the chart to the right.

| Wall Thickness Percent of OD | Maximum Percent Over & Under Nominal | Wall Thickness Percent of OD | Maximum Percent Over & Under Nominal | ||

|---|---|---|---|---|---|

| Under 1.499" ID | 1.500" ID & Over | Under 38.07mm ID | 38.07mm ID & Over | ||

| Under 10 | 10.0 | 7.5 | Under 10 | 10.0 | 7.5 |

| 10 to 25 | 10.0 | 6.0 | 10 to 25 | 10.0 | 6.0 |

| Over 25 | 12.5 | 7.5 | Over 25 | 12.5 | 7.5 |

| Feature | Honed Tubes | Standard Tubes |

|---|---|---|

| Material Type | Carbon/Alloy Steel (ST52, E355) | Carbon Steel |

| Surface Finish | Ra ≤0.4 µm (Honed/SR-B) | Ra ≥1.0 µm |

| Tolerance | H7–H9 | H11 or lower |

| Tensile Strength (MPa) | 515–600 | 400–500 |

| Applications | Hydraulic/Pneumatic Cylinders | General Piping |

| Cost | Higher (precision processing) | Lower |

| Key Advantage | Precision bore, extended seal life | Cost-effective for non-precision uses |

| Feature | Mechanical Tubes | Hydraulic Tubes | Structural Tubes |

|---|---|---|---|

| Material Type | Carbon/Alloy/Stainless Steel | Carbon/Stainless Steel | Carbon Steel |

| Surface Finish | Ra ≤ 0.8 µm | Ra ≤ 0.4 µm | Ra ≥ 1.0 µm |

| Tolerance | H8–H10 | H7–H9 | H11 or lower |

| Tensile Strength (MPa) | 420–850 | 340–630 | 400–600 |

| Applications | Machinery, Automotive, Structural | Hydraulic/Pneumatic Systems | Construction, Frameworks |

| Cost | Moderate | Moderate to High | Low to Moderate |

| Key Advantage | Versatility, precision | High precision, pressure resistance | Cost-effective for structural use |

Note: Mechanical tubes offer a balance of precision and strength, making them suitable for both machinery and structural applications, while hydraulic tubes prioritize pressure resistance and surface finish.

Explore mechanical tubes with targeted long-tail keywords for specifications, applications, and manufacturing.

Note: Mechanical tubes meet ASTM A519, DIN 2391, and EN 10305-1 standards, offering precision and strength. Contact suppliers for detailed specifications.

Mechanical Tubes are critical for a wide range of industries, delivering high strength, precision, and versatility in applications from automotive to renewable energy.

Used in exhaust systems, chassis, suspension components, and fuel delivery systems.

Supports structural frameworks, scaffolding, bridges, tunnels, and plumbing/HVAC systems.

Used in conveyors, robotic arms, hydraulic systems, shafts, cylinders, and machine frames.

Supports wind turbine frameworks, solar tracking systems, oil/gas pipelines, and power generation components.

Used in aircraft structures, rocket components, defense equipment, and hydraulic systems.

Supports tractor components, ground clearing equipment, and irrigation systems.

Used in frames, supports, and aesthetic elements for durable furniture designs.

Used in playground equipment, greenhouse structures, restaurant equipment, hospital beds, and garden tools.

Why Mechanical Tubes?

Their precision manufacturing, high-strength materials, and versatile applications ensure reliable performance across diverse industries.

Other structural pipes provide high strength and v...

Steel pipe for gas cylinder offers high-strength, ...

Seamless pipes for high-temperature applications o...