Vacuum-insulated Pipes For Ultra-low-temperature Fluid Transfer

Pipes for cryogenic devices ensure safe, efficient transfer of ultra-low-temperature fluids like lng and liquid nitrogen with superior insulation and durability.

Vacuum-insulated Pipes For Ultra-low-temperature Fluid Transfer

Pipes for cryogenic devices ensure safe, efficient transfer of ultra-low-temperature fluids like lng and liquid nitrogen with superior insulation and durability.

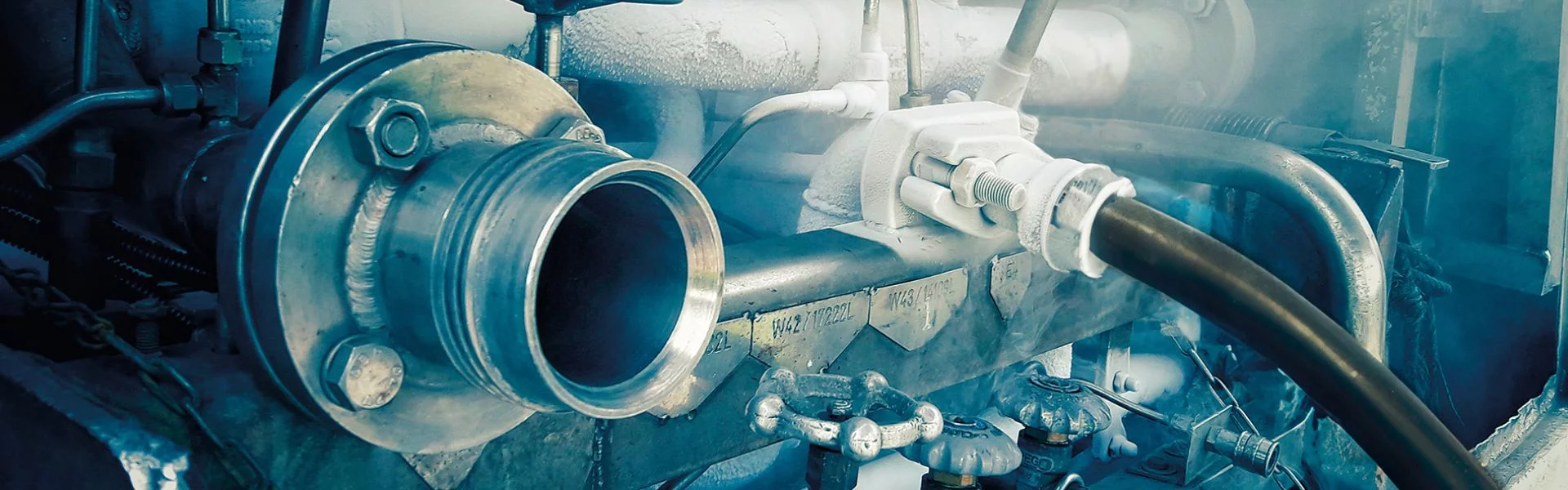

Pipes for Cryogenic Devices are specialized piping systems designed for safe and efficient transport of ultra-low-temperature fluids, such as liquid nitrogen (LN2), liquid oxygen (LOX), liquid argon (LAR), liquid helium (LHe), and liquefied natural gas (LNG), at temperatures below -150°C (-238°F). These cryogenic piping systems, often featuring vacuum insulation, minimize heat transfer to prevent gasification, ensuring thermal efficiency and safety in applications like aerospace, medical, and LNG processing. They comply with standards such as ASME B31.3 and EN 13480, offering durability in extreme conditions.

Constructed from high-grade materials like stainless steel (304, 316L) or nickel-based alloys (e.g., Inconel), vacuum insulated pipes utilize a double-walled design with a vacuum jacket to reduce heat ingress. Available in sizes from 1/2” to 40” (DN15–DN1000) and pressures up to 30 bar, these pipes offer flexible or rigid configurations with options like bayonet connections, flexible hoses, or welded joints for ease of installation. Advanced insulation, such as multilayer insulation (MLI) or perlite, ensures minimal heat leak, ideal for cryogenic storage and transfer systems.

Stainless steel cryogenic tubes are rigorously tested through vacuum leak tests, hydrostatic tests, and thermal cycling to ensure compliance with industry standards. With tensile strengths ranging from 485 MPa (316L SS) to 690 MPa (Inconel 625), they resist brittleness and thermal stress at cryogenic temperatures. Surface treatments like passivation and specialized coatings enhance corrosion resistance, while vacuum-jacketed designs provide up to 50 times better insulation than conventional foam, reducing boil-off gas (BOG) and operational costs.

Unlike standard piping, Pipes for Cryogenic Devices are engineered to handle extreme cold, preventing material embrittlement and ensuring safe transport of flammable or reactive fluids like liquid hydrogen (LH2). Their modularity makes them suitable for applications such as offshore LNG platforms, medical gas delivery, and food processing, where maintaining low temperatures is critical. These pipes withstand high pressures, thermal contraction, and environmental stresses, ensuring long-term reliability.

By addressing challenges like heat leak, frost buildup, and safety risks (e.g., cold burns, pressure buildup), low-temperature piping ensures efficient and secure fluid transfer in cryogenic devices. From aerospace fuel systems to medical cryopreservation, these pipes deliver unmatched performance, safety, and cost-efficiency, making them essential for industries handling cryogenic fluids.

| Usage | Specification | Steel Grade |

|---|---|---|

| Seamless and Welding Nominal Pipe used for Low Temperature | ASME SA-333M | Gr.3, Gr.6, Gr.8 and so on |

| Seamless Steel Pipe used for Low Temperature Pipeline | GB/T18984 | 16MnDG, 06Ni3MoDG, 06Ni9MoDG and so on |

Implement specifications such as ASME SA-333M, GB/T18984. The seamless steel tubes are applied for low temperature pressure vessel pipeline and low temperature heat exchanger pipeline.

Cryogenic piping is used to transport substances that have an extremely low temperature. The pipes must be able to withstand extreme changes in the liquids or gasses as they shift forms or thermal states. Cryogenic pipes are unique because they must be created with much higher quality materials, valves, and insulation than everyday pipes.

Our pipe systems use high-quality and flexible corrugated stainless-steel piping, providing versatility for various installation requirements and movement accommodation.

The flexible piping for cryogenic liquefied gases is vacuum-insulated and comes with high-quality "superinsulation" (vacuum + insulating material) for optimal thermal performance.

All superinsulated piping is pre-assembled in our factories. Cut to length, welded connections checked, and vacuum generated – ready for immediate installation and use.

| Grade | C (%) |

Si (%) |

Mn (%) |

P (max) (%) |

S (max) (%) |

Ni (%) |

Mo (%) |

V (%) |

|---|---|---|---|---|---|---|---|---|

| 16MnDG | 0.12-0.20 | 0.20-0.55 | 1.20-1.60 | 0.025 | 0.025 | — | — | — |

| 10MnDG | ≤0.13 | 0.17-0.37 | ≤1.35 | 0.025 | 0.025 | — | — | ≤0.07 |

| 09DG | ≤0.12 | 0.17-0.37 | ≤0.95 | 0.025 | 0.025 | — | — | ≤0.07 |

| 09Mn2VDG | ≤0.12 | 0.17-0.37 | ≤1.85 | 0.025 | 0.025 | — | — | ≤0.12 |

| 06Ni3MoDG | ≤0.08 | 0.17-0.37 | ≤0.85 | 0.025 | 0.025 | 2.5-3.7 | 0.15-0.30 | ≤0.05 |

| Grade | Tensile Strength (Rm/MPa) | Lower Yield Strength (Rcl/MPa) | Elongation (A/%) | |

|---|---|---|---|---|

| W.T.≤16mm | W.T.>16mm | |||

| 16MnDG | 490-665 | ≥325 | ≥315 | ≥30 |

| 10MnDG | ≥400 | ≥240 | — | ≥35 |

| 09DG | ≥385 | ≥210 | — | ≥35 |

| 09Mn2VDG | ≥450 | ≥300 | — | ≥30 |

| 06Ni3MoDG | ≥455 | ≥250 | — | ≥30 |

| Feature | GB/T 18984 16MnDG | ASTM A333 Grade 6 | JIS G3460 STPL450 |

|---|---|---|---|

| Material Type | Low-Alloy Steel (Seamless) | Carbon Steel (Seamless) | Carbon Steel (Seamless) |

| Temperature Range | -45°C to -196°C | -45°C to -195°C | -45°C to -100°C |

| Pressure Range | High pressure | High pressure | Moderate pressure |

| Corrosion Resistance | Good (With coatings) | Good | Moderate |

| Applications | Cryogenic piping, LNG transport | Low-temperature piping | Low-temperature systems |

| Tensile Strength (MPa) | 500–630 | ≥415 | ≥450 |

| Yield Strength (MPa) | ≥325 | ≥240 | ≥245 |

| Key Advantage | Optimized for cryogenic toughness | High low-temperature strength | Precision for low-temperature systems |

| Grade | Heat Treatment |

|---|---|

| 10# | Normalization: Normalizing temperature 880℃-940℃ |

| 20# | Normalization: Normalizing temperature 880℃-940℃ |

| 12CrMo | Normalized and tempered: Normalizing temperature 900℃-960℃, tempering temperature 670℃-730℃ |

| 15CrMo | Normalized and tempered: Normalizing temperature 900℃-960℃, tempering temperature 680℃-730℃ |

| 12Cr5MoI | Full annealing or isothermal annealing |

| Application | OD Range | WT Range | Length Range | Standards |

|---|---|---|---|---|

| Cracking Furnaces | 10-426 mm | 1.5-50 mm | 5-12 m | GB/T 9948, ASTM A335, EN 10216-2 |

| Heat Exchangers | 1/2" – 12" | SCH 40, 80, 160 | Up to 12 m | ASTM A213, A312, GB/T 9948 |

| Transfer Lines | 1/8" – 24" | SCH 40, 80, XXS | Up to 12 m | GB/T 9948, ASTM A335, GOST 9941 |

| Refinery Piping | 10-323 mm | 1.5-40 mm | 5-12 m | GB/T 9948, ASTM A106, EN 10216-2 |

GB/T 18984 seamless steel tubes are critical for low-temperature heat exchangers, cryogenic piping, and refrigeration systems, offering superior toughness and reliability.

Used in heat exchangers for cryogenic fluid processing.

Transports liquefied natural gas at low temperatures.

Supports cooling in industrial refrigeration units.

Used in low-temperature chemical processing.

Ensures safe LNG and gas transport in pipelines.

Used in cryogenic pressure vessel piping systems.

Other structural pipes provide high strength and v...

Steel pipe for gas cylinder offers high-strength, ...

Seamless pipes for high-temperature applications o...